中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (2): 238-249.DOI: 10.13304/j.nykjdb.2023.0362

• 生物制造 资源生态 • 上一篇

邓奕龙1( ), 王建安1, 顾少龙2, 张小全1, 苗晓辉3, 施守杰2, 段卫东3(

), 王建安1, 顾少龙2, 张小全1, 苗晓辉3, 施守杰2, 段卫东3( )

)

收稿日期:2023-05-21

接受日期:2023-07-28

出版日期:2025-02-15

发布日期:2025-02-14

通讯作者:

段卫东

作者简介:邓奕龙 E-mail:dyl19980321@gmail.com;

基金资助:

Yilong DENG1( ), Jianan WANG1, Shaolong GU2, Xiaoquan ZHANG1, Xiaohui MIAO3, Shoujie SHI2, Weidong DUAN3(

), Jianan WANG1, Shaolong GU2, Xiaoquan ZHANG1, Xiaohui MIAO3, Shoujie SHI2, Weidong DUAN3( )

)

Received:2023-05-21

Accepted:2023-07-28

Online:2025-02-15

Published:2025-02-14

Contact:

Weidong DUAN

摘要:

为优化烤烟上部叶烘烤工艺,以‘云烟87’为试验材料,当地常规烘烤工艺为对照(CK),分别在烟叶烘烤过程中的变黄期设置变温处理(T1:变温幅度±1 ℃,变温频率3 h;T2:变温幅度±1.5 ℃,变温频率5 h),利用相关性分析和逐步回归对烟叶颜色参数及色素的协同关系进行系统分析,研究烟叶烘烤过程中变温处理对烟叶外观质量的影响。结果表明, 3种工艺处理烟叶烘烤过程中的明度值(lightness value, L)、红度值(redness value, a)、黄度值(yellowness value, b)、饱和度值(chroma, C)、色相角(hue angle, h)、色泽比(color ratio, H)和色差值(color difference, ΔE)的变化趋势基本一致;烟叶内在色素的降解规律也较一致。当烟叶烘烤结束时,不同工艺处理烟叶的L、a、b值均存在显著差异,T1处理的L和b值最大,a值最小,即T1工艺处理变黄结束时及烤后烟叶的黄度值较好,烟叶颜色饱和度高,富有光泽。相关性分析表明,烟叶L值与a、b、C和H值呈显著或极显著正相关;L、a、b值与叶绿素a和叶绿素b呈显著或极显著负相关。T1工艺处理烟叶的叶绿素a(?1)、叶绿素b (?2)和类胡萝卜素含量(?3)与各颜色参数的回归方程分别为?1=-0.158-0.013a+0.005h(R2=0.931,F=122.08),?2=0.148-0.189H(R2=0.808,F=79.97),?3=0.051-0.003a+0.001b(R2=0.754,F=27.59),a、b、h和H与烟叶色素含量协同关系较大。T1工艺处理的还原糖、总糖及淀粉含量均降低,其中淀粉含量为4.65%,与优质烟叶淀粉含量要求(2%~4%)较为接近;烤后烟叶的上等烟和中上等烟比例均最大,外观质量和感官质量得以明显改善。综上所述,在38 ℃定温变黄的基础上采用幅度±1 ℃,频率3 h的正弦式程序控制的温度变化,能够促进上部叶颜色参数与色素含量协同变化,并提高烤后烟叶的质量。

中图分类号:

邓奕龙, 王建安, 顾少龙, 张小全, 苗晓辉, 施守杰, 段卫东. 变黄期变温烘烤对上部叶颜色参数与色素含量协同关系的影响[J]. 中国农业科技导报, 2025, 27(2): 238-249.

Yilong DENG, Jianan WANG, Shaolong GU, Xiaoquan ZHANG, Xiaohui MIAO, Shoujie SHI, Weidong DUAN. Effect of Variable Temperature During Yellowing Stage on Synergistic Relationship Between Color Parameters and Pigment Contents of Upper leaves[J]. Journal of Agricultural Science and Technology, 2025, 27(2): 238-249.

| 指标Index | 处理Treatment | 烘烤时间Curing time/h | 烤后烟叶 Cured tobacco leaves | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 36 | 48 | 60 | 72 | 84 | 96 | |||

| L | CK | 50.77±0.56 a | 57.64±0.60 b | 57.98±1.83 c | 68.11±1.65 ab | 66.58±0.91 b | 67.80±1.17 a | 65.75±1.98 a | 51.43±1.37 b |

| T1 | 53.80±0.72 a | 64.90±0.58 a | 70.11±1.49 a | 70.24±0.22 a | 70.29±0.83 a | 69.03±0.26 a | 65.99±1.05 a | 58.36±0.52 a | |

| T2 | 51.43±2.27 a | 57.09±0.16 b | 62.41±3.08 b | 67.17±2.47 b | 67.00±0.27 b | 65.45±2.10 b | 55.75±2.72 b | 48.30±2.02 c | |

| a | CK | -8.55±0.20 a | -3.37±0.30 ab | -1.86±0.65 b | 5.06±0.67 a | 5.56±0.16 b | 7.63±0.70 a | 8.51±0.09 a | 12.50±0.25 b |

| T1 | -7.65±0.55 a | -1.58±1.87 a | -1.02±0.14 b | 4.87±0.72 a | 7.20±0.94 a | 7.61±0.39 a | 7.82±0.62 a | 10.63±0.10 c | |

| T2 | -8.04±0.98 a | -4.38±0.09 b | 3.53±1.04 a | 5.39±0.47 a | 5.81±0.03 b | 5.98±0.55 b | 7.39±1.85 a | 13.83±0.16 a | |

| b | CK | 38.82±0.65 a | 53.13±0.97 b | 53.47±3.71 a | 58.97±1.81 b | 59.25±0.07 ab | 55.86±1.67 a | 53.72±1.22 a | 48.24±1.88 ab |

| T1 | 38.96±2.99 a | 55.72±1.24 a | 56.53±2.98 a | 62.71±1.53 a | 60.87±1.46 a | 56.15±3.37 a | 56.12±0.77 a | 51.80±1.12 a | |

| T2 | 37.58±1.61 a | 47.93±0.16 c | 56.42±1.51 a | 59.05±0.96 b | 55.82±2.13 b | 55.59±1.94 a | 45.98±2.20 b | 45.66±3.24 b | |

表1 烟叶烘烤过程中的L、a和b值

Table 1 L, a and b value of flue-cured tobacco leaves during curing

| 指标Index | 处理Treatment | 烘烤时间Curing time/h | 烤后烟叶 Cured tobacco leaves | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 36 | 48 | 60 | 72 | 84 | 96 | |||

| L | CK | 50.77±0.56 a | 57.64±0.60 b | 57.98±1.83 c | 68.11±1.65 ab | 66.58±0.91 b | 67.80±1.17 a | 65.75±1.98 a | 51.43±1.37 b |

| T1 | 53.80±0.72 a | 64.90±0.58 a | 70.11±1.49 a | 70.24±0.22 a | 70.29±0.83 a | 69.03±0.26 a | 65.99±1.05 a | 58.36±0.52 a | |

| T2 | 51.43±2.27 a | 57.09±0.16 b | 62.41±3.08 b | 67.17±2.47 b | 67.00±0.27 b | 65.45±2.10 b | 55.75±2.72 b | 48.30±2.02 c | |

| a | CK | -8.55±0.20 a | -3.37±0.30 ab | -1.86±0.65 b | 5.06±0.67 a | 5.56±0.16 b | 7.63±0.70 a | 8.51±0.09 a | 12.50±0.25 b |

| T1 | -7.65±0.55 a | -1.58±1.87 a | -1.02±0.14 b | 4.87±0.72 a | 7.20±0.94 a | 7.61±0.39 a | 7.82±0.62 a | 10.63±0.10 c | |

| T2 | -8.04±0.98 a | -4.38±0.09 b | 3.53±1.04 a | 5.39±0.47 a | 5.81±0.03 b | 5.98±0.55 b | 7.39±1.85 a | 13.83±0.16 a | |

| b | CK | 38.82±0.65 a | 53.13±0.97 b | 53.47±3.71 a | 58.97±1.81 b | 59.25±0.07 ab | 55.86±1.67 a | 53.72±1.22 a | 48.24±1.88 ab |

| T1 | 38.96±2.99 a | 55.72±1.24 a | 56.53±2.98 a | 62.71±1.53 a | 60.87±1.46 a | 56.15±3.37 a | 56.12±0.77 a | 51.80±1.12 a | |

| T2 | 37.58±1.61 a | 47.93±0.16 c | 56.42±1.51 a | 59.05±0.96 b | 55.82±2.13 b | 55.59±1.94 a | 45.98±2.20 b | 45.66±3.24 b | |

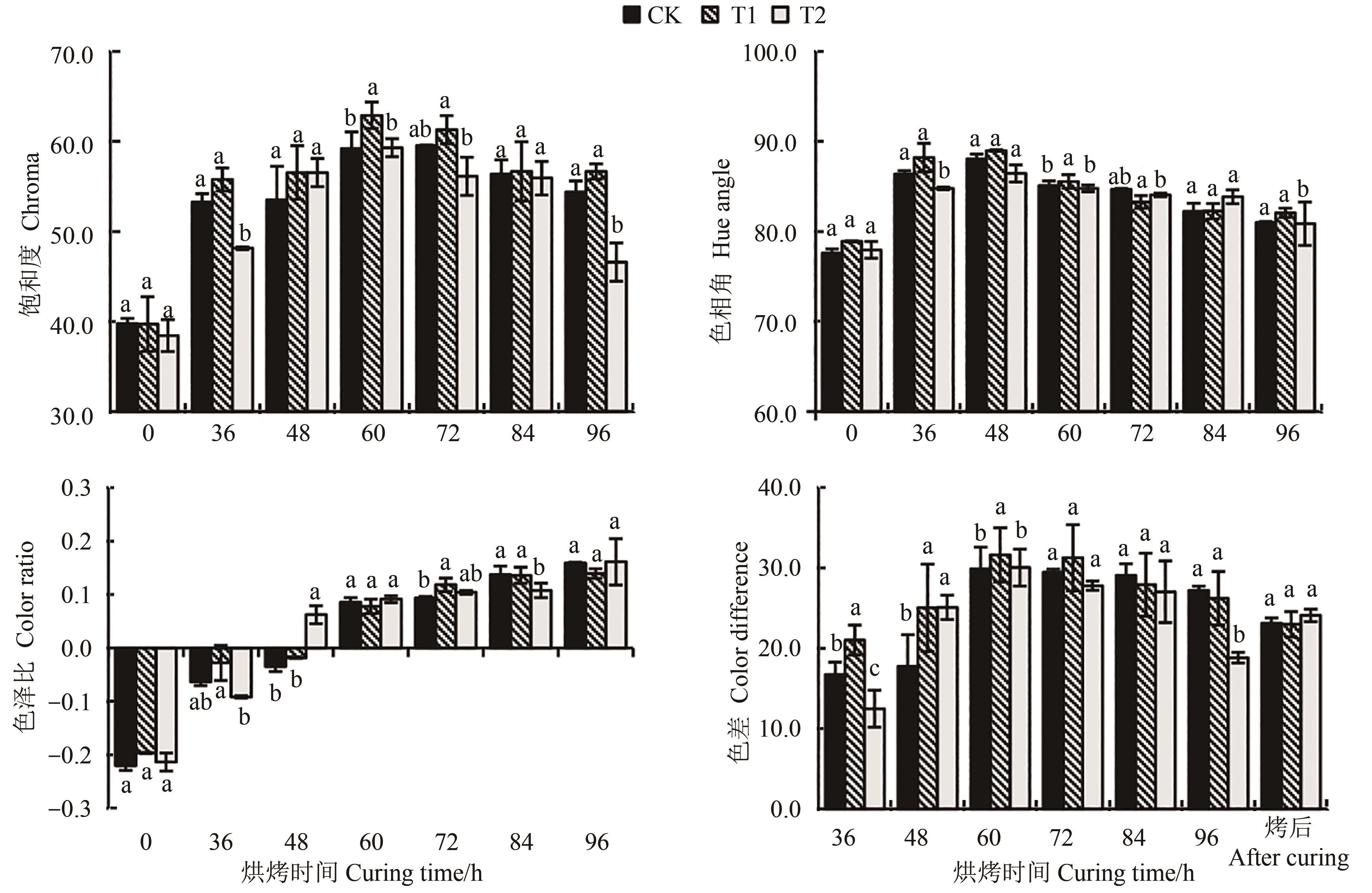

图4 烟叶烘烤过程中的C、h、H、ΔE注:不同小写字母表示同一时间不同处理间在P<0.05水平差异显著。

Fig. 4 C, h, H and ΔE of flue-cured tobacco leaves during curingNote: Different lowercase letters indicate significant differences between different treatments in same time at P<0.05 level.

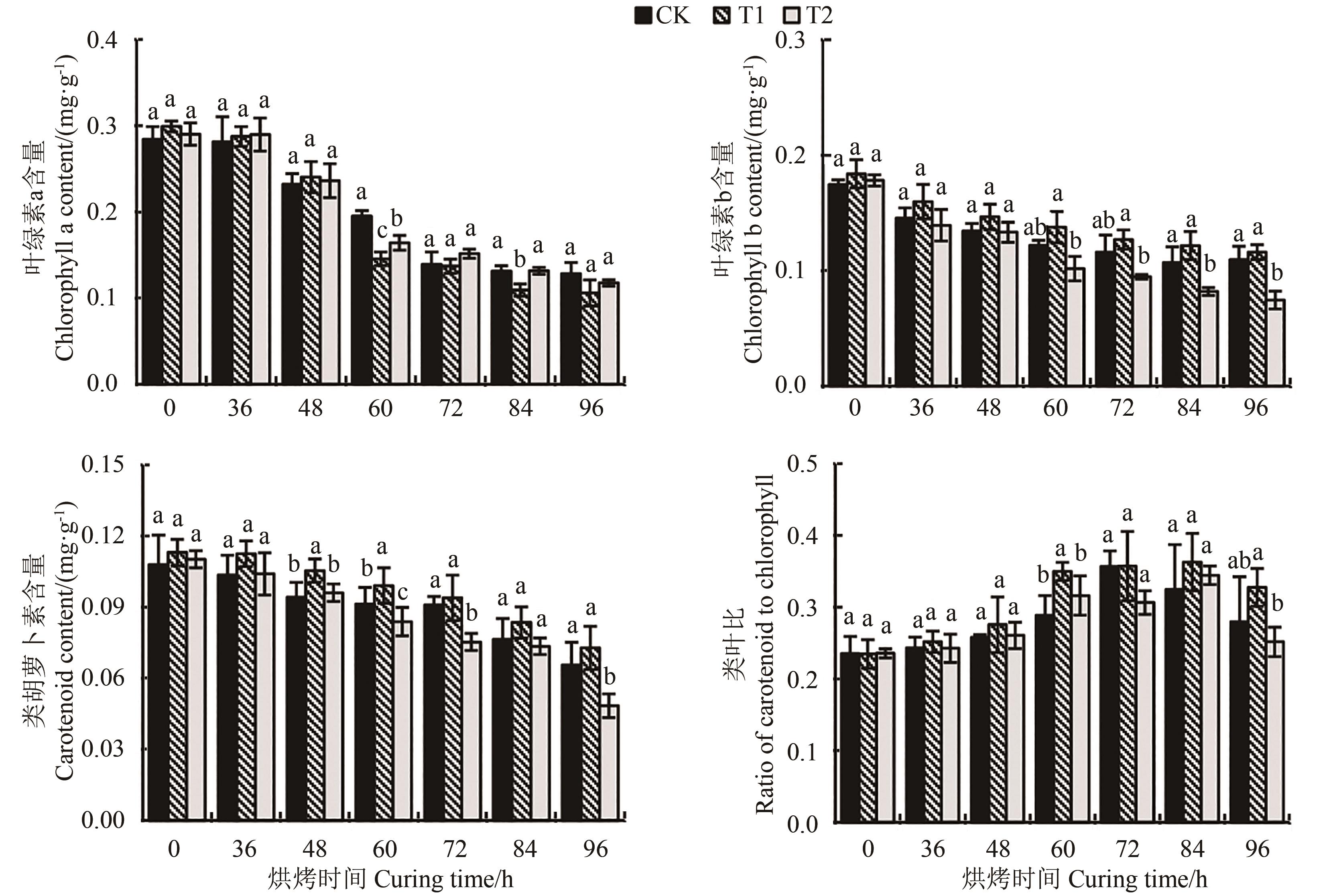

图5 烟叶烘烤过程中色素含量注:不同小写字母表示同一时间不同处理间在P<0.05水平差异显著。

Fig. 5 Pigment contents of flue-cured tobacco leaves during curingNote: Different lowercase letters indicate significant differences between different treatments in same time at P<0.05 level.

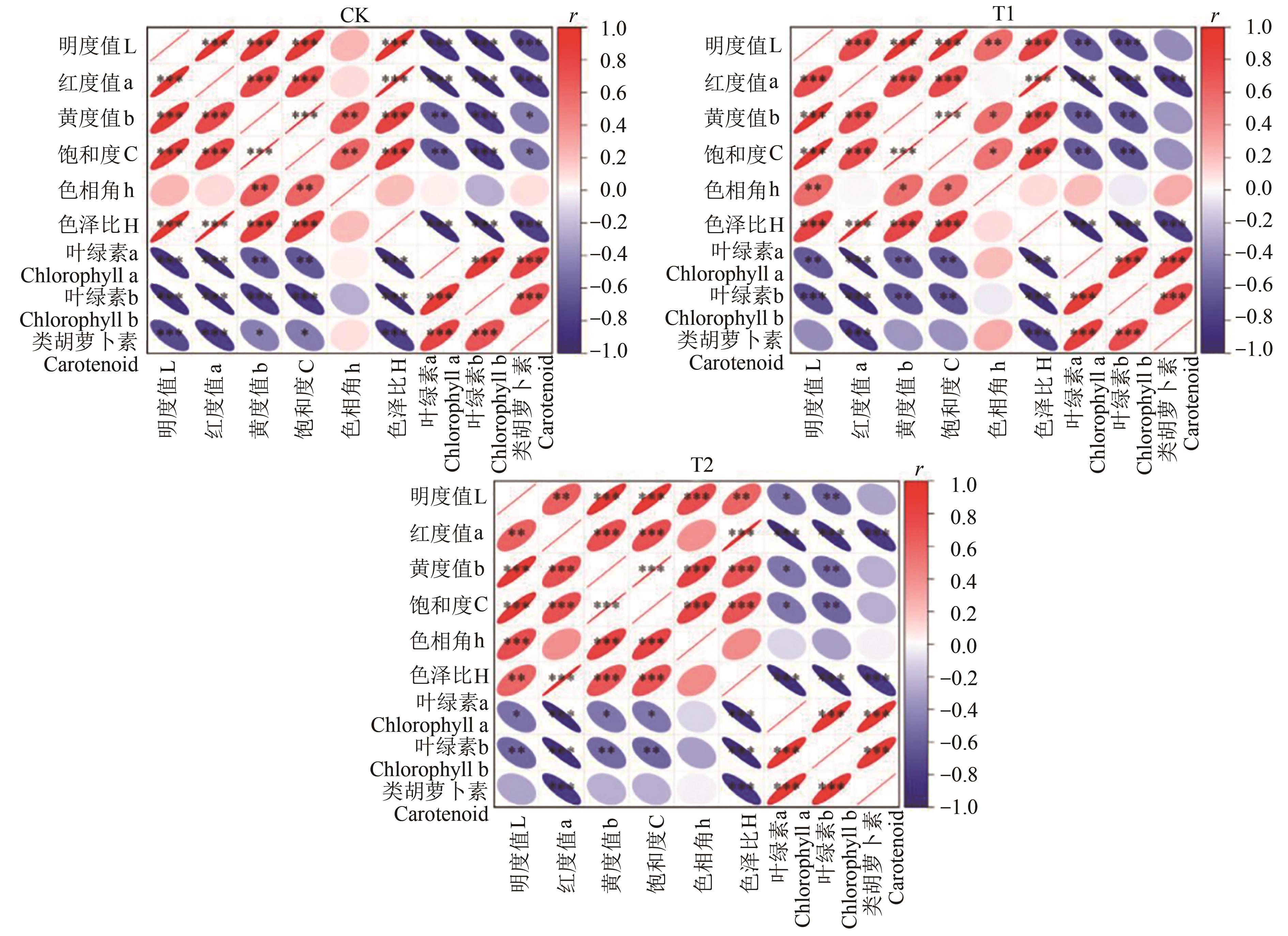

图6 烘烤过程中烟叶颜色参数与色素含量的相关性注:*、**和***分别表示在P<0.05、P<0.01和P<0.001水平相关。红色椭圆表示正相关,蓝色椭圆表示负相关,椭圆面积大小表示相关性大小。

Fig. 6 Correlation of color parameters and pigment contents of flue-cured tobacco leaves during curingNote: *, ** and *** indicate significant correlation at P<0.05, P<0.01 and P<0.001 levels, respectively. The red ellipse indicates positive correlation, the blue ellipse indicates negative correlation, and the size of the ellipse area indicates the size of the correlation.

处理 Treatment | 指标 Index | 回归方程 Regression equation | R2 | F值 F value |

|---|---|---|---|---|

| CK | 叶绿素a Chlorophyll a | ŷ1=0.229-0.024x2+0.675x6 | 0.897 | 78.18** |

| 叶绿素b Chlorophyll b | ŷ2=0.134-0.176x6 | 0.872 | 130.00** | |

| 类胡萝卜素 Carotenoid | ŷ3=0.094-0.002x2 | 0.611 | 29.85** | |

| T1 | 叶绿素a Chlorophyll a | ŷ1=-0.158-0.013x2+0.005x5 | 0.931 | 122.08** |

| 叶绿素b Chlorophyll b | ŷ2=0.148-0.189x6 | 0.808 | 79.97** | |

| 类胡萝卜素Carotenoid | ŷ3=0.051-0.003x2+0.001x3 | 0.754 | 27.59** | |

| T2 | 叶绿素a Chlorophyll a | ŷ1=-0.349-0.013x2+0.007x5 | 0.903 | 83.58** |

| 叶绿素b Chlorophyll b | ŷ2=0.123-0.253x6 | 0.820 | 86.42** | |

| 类胡萝卜素Carotenoid | ŷ3=0.037-0.199x6+0.003x4-0.002x1 | 0.894 | 48.00** |

表2 烟叶颜色参数与色素含量的逐步回归分析

Table 2 Stepwise regression analysis of color parameters and pigment contents of flue-cured tobacco leaves during curing

处理 Treatment | 指标 Index | 回归方程 Regression equation | R2 | F值 F value |

|---|---|---|---|---|

| CK | 叶绿素a Chlorophyll a | ŷ1=0.229-0.024x2+0.675x6 | 0.897 | 78.18** |

| 叶绿素b Chlorophyll b | ŷ2=0.134-0.176x6 | 0.872 | 130.00** | |

| 类胡萝卜素 Carotenoid | ŷ3=0.094-0.002x2 | 0.611 | 29.85** | |

| T1 | 叶绿素a Chlorophyll a | ŷ1=-0.158-0.013x2+0.005x5 | 0.931 | 122.08** |

| 叶绿素b Chlorophyll b | ŷ2=0.148-0.189x6 | 0.808 | 79.97** | |

| 类胡萝卜素Carotenoid | ŷ3=0.051-0.003x2+0.001x3 | 0.754 | 27.59** | |

| T2 | 叶绿素a Chlorophyll a | ŷ1=-0.349-0.013x2+0.007x5 | 0.903 | 83.58** |

| 叶绿素b Chlorophyll b | ŷ2=0.123-0.253x6 | 0.820 | 86.42** | |

| 类胡萝卜素Carotenoid | ŷ3=0.037-0.199x6+0.003x4-0.002x1 | 0.894 | 48.00** |

处理 Treatment | 烟碱 Nicotine | 还原糖 Reducing sugar | 总糖 Total sugar | 总氮 Total nitrogen | 钾 Potassium | 氯 Chlorine | 淀粉 Starch |

|---|---|---|---|---|---|---|---|

| CK | 2.31±0.06 b | 26.40±0.37 b | 36.10±0.87 b | 2.21±0.15 b | 1.60±0.25 a | 0.28±0.07 a | 5.35±0.16 b |

| T1 | 2.02±0.10 b | 23.20±0.07 c | 29.90±0.17 c | 2.02±0.10 b | 1.38±0.10 a | 0.27±0.06 a | 4.65±0.09 c |

| T2 | 3.24±0.20 a | 27.10±0.07 a | 37.90±0.11 a | 2.72±0.05 a | 1.48±0.09 a | 0.23±0.02 a | 6.44±0.14 a |

表3 3种工艺处理烟叶的化学成分 (%)

Table 3 Chemical composition of flue-cured tobacco leaves by three kinds of technology

处理 Treatment | 烟碱 Nicotine | 还原糖 Reducing sugar | 总糖 Total sugar | 总氮 Total nitrogen | 钾 Potassium | 氯 Chlorine | 淀粉 Starch |

|---|---|---|---|---|---|---|---|

| CK | 2.31±0.06 b | 26.40±0.37 b | 36.10±0.87 b | 2.21±0.15 b | 1.60±0.25 a | 0.28±0.07 a | 5.35±0.16 b |

| T1 | 2.02±0.10 b | 23.20±0.07 c | 29.90±0.17 c | 2.02±0.10 b | 1.38±0.10 a | 0.27±0.06 a | 4.65±0.09 c |

| T2 | 3.24±0.20 a | 27.10±0.07 a | 37.90±0.11 a | 2.72±0.05 a | 1.48±0.09 a | 0.23±0.02 a | 6.44±0.14 a |

处理 Treatment | 成熟度 Maturity | 颜色 Color | 油分 Tar | 身份 Thickness | 结构 Structure | 色度 Tint | 挂灰杂色 Surface dusting | 含青 Green content |

|---|---|---|---|---|---|---|---|---|

| CK | 成熟 Mature | 橘黄色 Orange | 有+ Exist+ | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 无 None |

| T1 | 成熟 Mature | 橘黄色 Orange | 多 Much | 适中- Moderate- | 尚疏松 Slightly loose | 浓 Concentrated | 微有 Slightly exist | 无 None |

| T2 | 成熟 Mature | 红棕色 Reddish brown | 有 Exist | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 微有 Slightly exist |

表4 3种工艺处理烟叶的外观质量

Table 4 Appearance quality evaluation of flue-cured tobacco leaves by 3 kinds of technology

处理 Treatment | 成熟度 Maturity | 颜色 Color | 油分 Tar | 身份 Thickness | 结构 Structure | 色度 Tint | 挂灰杂色 Surface dusting | 含青 Green content |

|---|---|---|---|---|---|---|---|---|

| CK | 成熟 Mature | 橘黄色 Orange | 有+ Exist+ | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 无 None |

| T1 | 成熟 Mature | 橘黄色 Orange | 多 Much | 适中- Moderate- | 尚疏松 Slightly loose | 浓 Concentrated | 微有 Slightly exist | 无 None |

| T2 | 成熟 Mature | 红棕色 Reddish brown | 有 Exist | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 微有 Slightly exist |

| 1 | 张烨,王松峰,许锡祥,等.烟叶烘烤中不同区段叶片含水量、色素和酶活性变化[J].中国烟草科学,2018,39(6):66-72. |

| ZHANG Y, WANG S F, XU X X, et al.. Changes of water content, pigments and enzymes activities in tobacco leaves of different sections during flue-curing process [J]. Chin. Tob. Sci., 2018, 39(6):66-72. | |

| 2 | 李晓辉,甄焕菊,牛慧伟,等.不同烘烤工艺对红花大金元上部烟叶烘烤质量的影响[J].山东农业科学,2022,54(5):79-83. |

| LI X H, ZHEN H J, NIU H W, et al.. Effects of different curing processes on curing quality of upper leaves of tobacco Honghuadajinyuan [J]. Shandong Agric. Sci., 2022, 54(5):79-83. | |

| 3 | 过伟民,郑劲民,常乃杰,等.基于温湿度时序数据的烟叶烘烤工艺特征分析[J].中国烟草学报,2022,28(5):56-63. |

| GUO W M, ZHENG J M, CHANG N J, et al.. Analysis of flue-curing process characteristics based on temperature and humidity time series data [J]. Acta Tab. Sin., 2022, 28(5):56-63. | |

| 4 | 李昱霖,赵亚峰,徐志强,等.烤烟分状态变风机频率烘烤工艺参数优化[J].中南农业科技,2023,44(1):69-73. |

| 5 | 王爱华,王松峰,管志坤,等.烤烟密集烘烤过程中阶梯升温变黄生理生化特性研究[J].中国烟草科学,2012,33(1):69-73. |

| WANG A H, WANG S F, GUAN Z K, et al.. Physiology and biochemistry characters of step temperature yellowing during bulk curing process of tobacco leaves [J]. Chin. Tob. Sci., 2012, 33(1):69-73. | |

| 6 | 王鹏泽,来苗,陶陶,等.不同香型烤烟主要香味物质成分与香韵指标的关系研究[J].中国农业科技导报,2015,17(3):126-135. |

| WANG P Z, LAI M, TAO T, et al.. Relationships between main aroma constituents and aroma notes index of flue-cured tobacco leaves of different flavor styles [J]. J. Agric. Sci. Technol., 2015, 17(3):126-135. | |

| 7 | JIA J X, ZHANG M J, ZHAO J H, et al.. The effects of increasing the dry-bulb temperature during the stem-drying stage on the quality of upper leaves of flue-cured tobacco [J/OL]. Processes, 2023, 11(3):726 [2023-04-10]. . |

| 8 | WU S J, GUO Y S, JOAN H I, et al.. ITRAQ-based comparative proteomic analysis reveals high temperature accelerated leaf senescence of tobacco (Nicotiana tabacum L.) during flue-curing [J]. Genomics, 2020, 112(5):3075-3088. |

| 9 | 王建安,范艺宽,张同庆,等.密集烤房内置式生物质供热炉体的设计与试验[J].中国烟草学报,2021,27(4):36-44. |

| WANG J A, FAN Y K, ZHANG T Q, et al.. Design and test of biomass furnace in intensive baking room [J]. Acta Tab. Sin., 2021, 27(4):36-44. | |

| 10 | CHEN Z G, HUANG J R, PU H Y, et al.. The effects of temperature on starch molecular conformation and hydrogen bonding [J/OL]. Starch‐Stärke, 2022, 74(7-8):2100288 [2023-04-10]. . |

| 11 | ZHANG W J, DONG X L, LIN M S, et al.. Curing technology for improving the quality of upper tobacco leaves [J]. Asian J. Agric. Res., 2018, 10(11):68-74. |

| 12 | 王爱华,徐秀红,王松峰,等.变黄温度对烤烟烘烤过程中生理指标及烤后质量的影响[J].中国烟草学报,2008,14(1):27-31. |

| WANG A H, XU X H, WANG S F, et al.. Effect of temperature in yellowing stage on physiological indices and quality of flue-cured tobacco [J]. Acta Tab. Sin., 2008, 14(1):27-31. | |

| 13 | 任杰,王涛,饶智,等.不同变黄变筋温度对红花大金元香气物质含量的影响[J].中国烟草科学,2017,38(3):61-66. |

| REN J, WANG T, RAO Z, et al.. Effects of different leaf-yellowing and midrib-yellowing temperature on aroma constituents of Honghuadajinyuan [J]. Chin. Tob. Sci., 2017, 38(3):61-66. | |

| 14 | 高相彬,宗胜杰,孟智勇,等.变黄期温湿度对豫烟10号碳代谢及烤后品质的影响[J].西南农业学报,2019,32(10):2454-2458. |

| GAO X B, ZONG S J, MENG Z Y, et al.. Effect of temperature and humidity during yellowing stage on carbon metabolism and cured quality of Yuyan 10 [J]. Southwest China J. Agric. Sci., 2019, 32(10):2454-2458. | |

| 15 | 孟智勇,李建华,马浩波,等.烘烤工艺对豫中浓香型烤烟上六片烟叶品质的影响[J].河南农业科学,2021,50(10):154-162. |

| MENG Z Y, LI J H, MA H B, et al.. Effect of curing technology on the quality of upper six leaves of strong flavor type flue‑cured tobacco grown in central Henan [J]. J. Henan Agric. Sci., 2021, 50(10):154-162. | |

| 16 | 裴晓东,王涛,李帆,等.密集烘烤过程中烤烟上部叶颜色参数与主要化学成分变化[J].华北农学报,2012,27():218-222. |

| PEI X D, WANG T, LI F, et al.. Relationship between changes of color parameters and chemical components of upper flue-cured tobacco leaves during bulk-curing process [J]. Acta Agric. Boreal-Sin., 2012, 27(S1):218-222. | |

| 17 | 张佳佳,过伟民,段卫东,等.上6片烟叶烘烤过程中水分与颜色及化学成分的协同变化[J].烟草科技,2021,54(3):17-23, 57. |

| ZHANG J J, GUO W M, DUAN W D, et al.. Coordinated variations of moisture content, color and chemical components of top six upper leaves during flue-curing [J]. Tob. Sci. Technol., 2021, 54(3):17-23, 57. | |

| 18 | 贺帆,王涛,王梅,等.烘烤过程中烟叶颜色变化与主要化学成分的关系[J].中国烟草学报,2014,20(6):97-102. |

| HE F, WANG T, WANG M, et al.. Relationship between color changes and chemical components of flue-cured tobacco leaves during curing [J]. Acta Tab. Sin., 2014, 20(6):97-102. | |

| 19 | 王学奎,黄见良.植物生理生化实验原理和技术[M].2版.北京:高等教育出版社,2014: 1-324. |

| 20 | 国家烟草专卖局. 烟草及烟草制品总植物碱的测定连续流动法: [S].北京:中国标准出版社,2002. |

| 21 | 国家烟草专卖局. 烟草及烟草制品总氮的测定连续流动法: [S].北京:中国标准出版社,2002. |

| 22 | 国家烟草专卖局. 烟草及烟草制品水溶性糖的测定连续流动法: [S].北京:中国标准出版社,2002. |

| 23 | 国家烟草专卖局. 烟草及烟草制品钾的测定连续流动法: [S].北京:中国标准出版社,2007. |

| 24 | 国家烟草专卖局. 烟草及烟草制品氯的测定连续流动法: [S].北京:中国标准出版社,2011. |

| 25 | 国家烟草专卖局. 烟草及烟草制品淀粉的测定连续流动法: [S].北京:中国标准出版社,2013. |

| 26 | 国家烟草专卖局. 烤烟: [S].北京:中国标准出版社,1992. |

| 27 | 国家烟草专卖局. 烤烟-烟叶质量风格特色感官评价方法: [S].北京:中国标准出版社,2015. |

| 28 | LIU A M, YUAN K L, XU H Q, et al.. Proteomic and metabolomic revealed differences in the distribution and synthesis mechanism of aroma precursors in Yunyan 87 tobacco leaf, stem, and root at the seedling stage [J]. ACS Omega, 2022, 7(37):33295-33306. |

| 29 | 丁根胜,张庆明,巴金莎,等.烟叶颜色色度学指标与烤烟品质的关系分析[J].中国烟草科学,2011,32(4):14-18. |

| DING G S, ZHANG Q M, BA J S, et al.. Analysis of relationship between colorimetry indices and quality of flue-cured tobacco [J]. Chin. Tob. Sci., 2011, 32(4):14-18. | |

| 30 | TANG Z X, CHEN L L, CHEN Z B, et al.. Climatic factors determine the yield and quality of Honghe flue-cured tobacco [J/OL]. Sci. Rep., 2020, 10(1):19868 [2023-04-10]. . |

| 31 | 武圣江,周义和,宋朝鹏,等.密集烘烤过程中烤烟上部叶质地和色度变化研究[J].中国烟草学报,2010,16(5):72-77. |

| WU S J, ZHOU Y H, SONG Z P, et al.. Study on texture and col or change in upper leaves during bulk flue-curing [J]. Acta Tab. Sin., 2010, 16(5):72-77. | |

| 32 | 孟可爱,聂荣邦,肖春生,等.密集烘烤过程中烟叶水分和色素含量的动态变化[J].湖南农业大学学报(自然科学版),2006, 32(2):144-148. |

| MENG K A, NIE R B, XIAO C S, et al.. Changes of pigment and moisture content in cured tobacco leaves during bulk curing process [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2006, 32(2):144-148. | |

| 33 | 杨立均,宫长荣,马京民.烘烤过程中烟叶色素的降解及与化学成分的相关分析[J].中国烟草科学,2002(2):5-7. |

| YANG L J, GONG C R, MA J M, et al.. Degradation of pigment in tobacco leaf during flue-curing process and relative analysis with chemical compositions [J]. Chin. Tob. Sci., 2002(2):5-7. | |

| 34 | 杨虹琦,周冀衡,杨述元,等.不同产区烤烟中主要潜香型物质对评吸质量的影响研究[J].湖南农业大学学报(自然科学版),2005, 31(1):11-14. |

| YANG H Q, ZHOU J H, YANG S Y, et al.. Effect on chiefly latent fragrant substance on panel test flue-cured tobacco from different producing area [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2005, 31(1):11-14. | |

| 35 | ZONG J J, HE X, LIN Z L, et al.. Effect of two drying methods on chemical transformations in flue-cured tobacco [J]. Dry. Technol., 2022, 40(1):188-196. |

| 36 | LI C, JI J, WANG G, et al.. Over-expression of LcPDS, LcZDS and LcCRTISO genes from wolfberry for carotenoid biosynthesis, enhanced carotenoid accumulation, and salt tolerance in tobacco [J/OL]. Front. Plant Sci., 2020, 11:119 [2023-04-10]. . |

| 37 | 董淑君,黄明迪,王耀锋,等.密集烤房与普通烤房烘烤中烟叶色素和多酚含量的变化分析[J].中国烟草科学,2015,36(1):90-95. |

| DONG S J, HUANG M D, WANG Y F, et al.. Change difference of pigment and polyphenol contents between bulk-curing barn and traditional flue-curing barn during curing process [J]. Chin. Tob. Sci., 2015, 36(1):90-95. | |

| 38 | ZHANG H H, XU Z S, GUO K W, et al.. Toxic effects of heavy metal Cd and Zn on chlorophyll, carotenoid metabolism and photosynthetic function in tobacco leaves revealed by physiological and proteomics analysis [J/OL]. Ecotoxicol. Environ. Saf., 2020, 202:110856 [2023-04-10]. . |

| [1] | 时晓宇, 焦连庆, 于敏, 田义新, 焦安妮, 栾依琳. 多维度评价及优化黄芪瞬时高温灭菌工艺[J]. 中国农业科技导报, 2024, 26(7): 223-233. |

| [2] | 张二豪, 刘盼盼, 何萍, 简阅, 徐雨婷, 陈诚欣, 禄亚洲, 兰小中, 索朗桑姆. 甘青青兰根际土壤理化性质及微生物群落结构特征分析[J]. 中国农业科技导报, 2024, 26(3): 201-213. |

| [3] | 刘峰峰, 吴明, 周迎辉, 吴勇, 田嘉树, 许嘉阳, 许自成, 何结望. 生长素与钼配施对烤烟上部叶生理代谢及品质的影响[J]. 中国农业科技导报, 2024, 26(2): 208-215. |

| [4] | 梁永进, 朱睿璇, 韦贝蕾, 袁小迈, 成武洋, 彭博, 王梓廷, 韦建玉. 有机肥配施对我国烟叶品质影响的整合分析[J]. 中国农业科技导报, 2024, 26(12): 164-175. |

| [5] | 路宁宁, 陈凌云, 杨太新, 杨树林, 刘国库. 珊瑚菜果实形成与内源激素含量的相关性分析[J]. 中国农业科技导报, 2024, 26(1): 63-69. |

| [6] | 贾滢暄, 张树林, 张达娟, 戴伟, 毕相东. 磷恢复对磷饥饿铜绿微囊藻光合色素和部分抗氧化酶活性的影响[J]. 中国农业科技导报, 2024, 26(1): 70-77. |

| [7] | 胡永涛, 汪代斌, 陈益银, 杨超, 郑林林, 史宏志, 王建安. 不同成熟度鲜烟素质对烤后烟叶品质贡献度的研究[J]. 中国农业科技导报, 2023, 25(8): 157-164. |

| [8] | 刘鹏飞, 陆小双, 迪力木拉提·热合曼, 唐努尔·斯拉依, 曲延英, 陈全家, 邓晓娟. 陆地棉棉籽主要品质性状与农艺性状的遗传变异分析[J]. 中国农业科技导报, 2023, 25(8): 22-32. |

| [9] | 周文, 郭笑恒, 徐锐, 王晓丽, 牛慧伟, 韩丹, 邵惠芳. 烤烟间作半夏对烤烟生长及产量和品质的影响[J]. 中国农业科技导报, 2023, 25(7): 161-169. |

| [10] | 麻仲花, 陈娟, 吴娜, 满本菊, 王晓港, 者永清, 刘吉利. 盐胁迫与供磷水平对柳枝稷苗期光合特性与总生物量的影响[J]. 中国农业科技导报, 2023, 25(6): 190-200. |

| [11] | 刘咏艳, 宋正熊, 金佳威, 王静, 徐敏, 周俊学, 李占民, 赵世民, 符云鹏, 代晓燕. 钼锌营养对烤烟生理特性及品质的影响[J]. 中国农业科技导报, 2023, 25(6): 216-224. |

| [12] | 赵文军, 杨继周, 尹梅, 陈检锋, 薛开政, 胡保文, 付利波, 王伟, 王志远, 杨艳鲜, 陈华. 绿肥模式下减量施氮对烤烟产量与品质的影响[J]. 中国农业科技导报, 2023, 25(4): 189-196. |

| [13] | 侯志雄, 井长青, 王公鑫, 郭文章, 赵苇康. 1998—2018年北疆天然草地植被覆盖度时空变化及其与气象因子的关系[J]. 中国农业科技导报, 2023, 25(2): 140-151. |

| [14] | 黄丽芳, 龙宇宙, 李金芹, 董云萍, 王晓阳, 陈鹏, 王宪文, 闫林. 低温胁迫对小粒种咖啡幼苗生理特性的影响[J]. 中国农业科技导报, 2023, 25(2): 60-67. |

| [15] | 范业赓, 丘立杭, 陈荣发, 周慧文, 李燕娇, 闫海锋, 罗含敏, 周忠凤, 邓宇驰, 吴建明. 不同分蘖特性甘蔗品种生产力差异和相关性研究[J]. 中国农业科技导报, 2023, 25(12): 35-43. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号