Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (10): 210-220.DOI: 10.13304/j.nykjdb.2022.0313

• BIO-MANUFACTURING & RESOURCE AND ECOLOGY • Previous Articles

Yingmei WANG1,2( ), Yanzhuang WANG1, Yingjie LI1, Yan LI1, Miao HE1, Xiaojing WANG1, Hongbin DU1(

), Yanzhuang WANG1, Yingjie LI1, Yan LI1, Miao HE1, Xiaojing WANG1, Hongbin DU1( )

)

Received:2022-04-18

Accepted:2022-10-08

Online:2023-10-15

Published:2023-10-27

Contact:

Hongbin DU

王应梅1,2( ), 王艳壮1, 李莹杰1, 李燕1, 何苗1, 王晓璟1, 杜红斌1(

), 王艳壮1, 李莹杰1, 李燕1, 何苗1, 王晓璟1, 杜红斌1( )

)

通讯作者:

杜红斌

作者简介:王应梅 E-mail:1543056863@qq.com;

基金资助:CLC Number:

Yingmei WANG, Yanzhuang WANG, Yingjie LI, Yan LI, Miao HE, Xiaojing WANG, Hongbin DU. Research on Acid-base Pretreatment and Fermentation Process of Walnut Leaf Matrixing[J]. Journal of Agricultural Science and Technology, 2023, 25(10): 210-220.

王应梅, 王艳壮, 李莹杰, 李燕, 何苗, 王晓璟, 杜红斌. 核桃树叶基质化的酸碱前处理与发酵工艺研究[J]. 中国农业科技导报, 2023, 25(10): 210-220.

| 处理Treatment | 是否进行前处理Ammonia pretreatment | 鼠李糖脂添加量Rhamnolipid added/% | |

|---|---|---|---|

| A | A0 | 是Yes | — |

| A3 | 是Yes | 0.3 | |

| A6 | 是Yes | 0.6 | |

| A9 | 是Yes | 0.9 | |

| B | B0 | 否No | — |

| B3 | 否No | 0.3 | |

| B6 | 否No | 0.6 | |

| B9 | 否No | 0.9 | |

Table 1 Walnut leaves fermentation treatments

| 处理Treatment | 是否进行前处理Ammonia pretreatment | 鼠李糖脂添加量Rhamnolipid added/% | |

|---|---|---|---|

| A | A0 | 是Yes | — |

| A3 | 是Yes | 0.3 | |

| A6 | 是Yes | 0.6 | |

| A9 | 是Yes | 0.9 | |

| B | B0 | 否No | — |

| B3 | 否No | 0.3 | |

| B6 | 否No | 0.6 | |

| B9 | 否No | 0.9 | |

| 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking | 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking |

|---|---|---|---|---|---|---|---|---|---|

| C1H1 | 0.626 | 16 | 0.687 | 8 | C4H1 | 0.640 | 13 | 0.591 | 20 |

| C1H2 | 0.684 | 5 | 0.711 | 4 | C4H2 | 0.602 | 21 | 0.560 | 26 |

| C1H3 | 0.641 | 12 | 0.685 | 9 | C4H3 | 0.551 | 28 | 0.562 | 25 |

| C1H4 | 0.646 | 9 | 0.695 | 7 | C4H4 | 0.548 | 29 | 0.537 | 29 |

| C1H5 | 0.707 | 3 | 0.756 | 2 | C4H5 | 0.518 | 30 | 0.494 | 30 |

| C2H1 | 0.765 | 1 | 0.766 | 1 | C5H1 | 0.635 | 15 | 0.604 | 18 |

| C2H2 | 0.746 | 2 | 0.749 | 3 | C5H2 | 0.613 | 19 | 0.625 | 12 |

| C2H3 | 0.677 | 6 | 0.705 | 6 | C5H3 | 0.615 | 18 | 0.612 | 14 |

| C2H4 | 0.624 | 17 | 0.673 | 10 | C5H4 | 0.555 | 26 | 0.553 | 27 |

| C2H5 | 0.686 | 4 | 0.711 | 5 | C5H5 | 0.600 | 22 | 0.582 | 23 |

| C3H1 | 0.586 | 25 | 0.604 | 17 | C6H1 | 0.638 | 14 | 0.588 | 21 |

| C3H2 | 0.588 | 24 | 0.580 | 24 | C6H2 | 0.663 | 7 | 0.606 | 16 |

| C3H3 | 0.607 | 20 | 0.610 | 15 | C6H3 | 0.642 | 11 | 0.625 | 11 |

| C3H4 | 0.590 | 23 | 0.582 | 22 | C6H4 | 0.553 | 27 | 0.544 | 28 |

| C3H5 | 0.644 | 10 | 0.595 | 19 | C6H5 | 0.647 | 8 | 0.622 | 13 |

Table 2 Ranking of correlation degree on physical and chemical indexes of walnut leaves treated by different pretreatment

| 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking | 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking |

|---|---|---|---|---|---|---|---|---|---|

| C1H1 | 0.626 | 16 | 0.687 | 8 | C4H1 | 0.640 | 13 | 0.591 | 20 |

| C1H2 | 0.684 | 5 | 0.711 | 4 | C4H2 | 0.602 | 21 | 0.560 | 26 |

| C1H3 | 0.641 | 12 | 0.685 | 9 | C4H3 | 0.551 | 28 | 0.562 | 25 |

| C1H4 | 0.646 | 9 | 0.695 | 7 | C4H4 | 0.548 | 29 | 0.537 | 29 |

| C1H5 | 0.707 | 3 | 0.756 | 2 | C4H5 | 0.518 | 30 | 0.494 | 30 |

| C2H1 | 0.765 | 1 | 0.766 | 1 | C5H1 | 0.635 | 15 | 0.604 | 18 |

| C2H2 | 0.746 | 2 | 0.749 | 3 | C5H2 | 0.613 | 19 | 0.625 | 12 |

| C2H3 | 0.677 | 6 | 0.705 | 6 | C5H3 | 0.615 | 18 | 0.612 | 14 |

| C2H4 | 0.624 | 17 | 0.673 | 10 | C5H4 | 0.555 | 26 | 0.553 | 27 |

| C2H5 | 0.686 | 4 | 0.711 | 5 | C5H5 | 0.600 | 22 | 0.582 | 23 |

| C3H1 | 0.586 | 25 | 0.604 | 17 | C6H1 | 0.638 | 14 | 0.588 | 21 |

| C3H2 | 0.588 | 24 | 0.580 | 24 | C6H2 | 0.663 | 7 | 0.606 | 16 |

| C3H3 | 0.607 | 20 | 0.610 | 15 | C6H3 | 0.642 | 11 | 0.625 | 11 |

| C3H4 | 0.590 | 23 | 0.582 | 22 | C6H4 | 0.553 | 27 | 0.544 | 28 |

| C3H5 | 0.644 | 10 | 0.595 | 19 | C6H5 | 0.647 | 8 | 0.622 | 13 |

| 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking | 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking |

|---|---|---|---|---|---|---|---|---|---|

| N1H1 | 0.617 | 19 | 0.610 | 19 | N4H1 | 0.646 | 7 | 0.623 | 16 |

| N1H2 | 0.625 | 17 | 0.654 | 9 | N4H2 | 0.662 | 6 | 0.637 | 13 |

| N1H3 | 0.625 | 16 | 0.666 | 6 | N4H3 | 0.636 | 9 | 0.631 | 14 |

| N1H4 | 0.707 | 2 | 0.739 | 1 | N4H4 | 0.636 | 10 | 0.630 | 15 |

| N1H5 | 0.632 | 11 | 0.683 | 5 | N4H5 | 0.680 | 3 | 0.697 | 3 |

| N2H1 | 0.664 | 5 | 0.659 | 8 | N5H1 | 0.581 | 26 | 0.522 | 30 |

| N2H2 | 0.597 | 22 | 0.646 | 10 | N5H2 | 0.561 | 27 | 0.540 | 29 |

| N2H3 | 0.588 | 23 | 0.577 | 24 | N5H3 | 0.546 | 29 | 0.571 | 26 |

| N2H4 | 0.532 | 30 | 0.545 | 28 | N5H4 | 0.613 | 20 | 0.577 | 23 |

| N2H5 | 0.626 | 15 | 0.644 | 11 | N5H5 | 0.602 | 21 | 0.619 | 17 |

| N3H1 | 0.629 | 13 | 0.601 | 21 | N6H1 | 0.621 | 18 | 0.639 | 12 |

| N3H2 | 0.732 | 1 | 0.698 | 2 | N6H2 | 0.559 | 28 | 0.573 | 25 |

| N3H3 | 0.630 | 12 | 0.599 | 22 | N6H3 | 0.643 | 8 | 0.663 | 7 |

| N3H4 | 0.584 | 25 | 0.617 | 18 | N6H4 | 0.587 | 24 | 0.557 | 27 |

| N3H5 | 0.627 | 14 | 0.602 | 20 | N6H5 | 0.677 | 4 | 0.695 | 4 |

Table 3 Correlation degree of physical and chemical indexes of walnut leaves treated by different concentration of hartshorn and different duration

| 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking | 处理Treatment | 等权关联度Equai-weighted correlation | 排序Ranking | 加权关联度Weighted correlation | 排序Ranking |

|---|---|---|---|---|---|---|---|---|---|

| N1H1 | 0.617 | 19 | 0.610 | 19 | N4H1 | 0.646 | 7 | 0.623 | 16 |

| N1H2 | 0.625 | 17 | 0.654 | 9 | N4H2 | 0.662 | 6 | 0.637 | 13 |

| N1H3 | 0.625 | 16 | 0.666 | 6 | N4H3 | 0.636 | 9 | 0.631 | 14 |

| N1H4 | 0.707 | 2 | 0.739 | 1 | N4H4 | 0.636 | 10 | 0.630 | 15 |

| N1H5 | 0.632 | 11 | 0.683 | 5 | N4H5 | 0.680 | 3 | 0.697 | 3 |

| N2H1 | 0.664 | 5 | 0.659 | 8 | N5H1 | 0.581 | 26 | 0.522 | 30 |

| N2H2 | 0.597 | 22 | 0.646 | 10 | N5H2 | 0.561 | 27 | 0.540 | 29 |

| N2H3 | 0.588 | 23 | 0.577 | 24 | N5H3 | 0.546 | 29 | 0.571 | 26 |

| N2H4 | 0.532 | 30 | 0.545 | 28 | N5H4 | 0.613 | 20 | 0.577 | 23 |

| N2H5 | 0.626 | 15 | 0.644 | 11 | N5H5 | 0.602 | 21 | 0.619 | 17 |

| N3H1 | 0.629 | 13 | 0.601 | 21 | N6H1 | 0.621 | 18 | 0.639 | 12 |

| N3H2 | 0.732 | 1 | 0.698 | 2 | N6H2 | 0.559 | 28 | 0.573 | 25 |

| N3H3 | 0.630 | 12 | 0.599 | 22 | N6H3 | 0.643 | 8 | 0.663 | 7 |

| N3H4 | 0.584 | 25 | 0.617 | 18 | N6H4 | 0.587 | 24 | 0.557 | 27 |

| N3H5 | 0.627 | 14 | 0.602 | 20 | N6H5 | 0.677 | 4 | 0.695 | 4 |

| 指标Index | 草酸 Oxalic acid | 氨水 Ammonia |

|---|---|---|

| 溶液浓度Solution concentration/% | 1.00 | 0.50 |

| 处理时长Processing time/h | 0.50 | 2.00 |

| 容重Bulk density/(g·cm-3) | 0.13 | 0.11 |

| 总孔隙度Total porosity/% | 74.23 | 75.93 |

| 通气孔隙度Ventilation porosity/% | 34.11 | 35.40 |

| 持水孔隙度Water holding porosity/% | 40.12 | 40.53 |

| 气水比Gas water ratio | 0.86 | 0.87 |

| pH | 3.09 | 6.61 |

| 电导率EC/(mS·cm-1) | 0.98 | 0.99 |

Table 4 Physicochemical properties of walnut leaves treated with oxalic acid and ammonia

| 指标Index | 草酸 Oxalic acid | 氨水 Ammonia |

|---|---|---|

| 溶液浓度Solution concentration/% | 1.00 | 0.50 |

| 处理时长Processing time/h | 0.50 | 2.00 |

| 容重Bulk density/(g·cm-3) | 0.13 | 0.11 |

| 总孔隙度Total porosity/% | 74.23 | 75.93 |

| 通气孔隙度Ventilation porosity/% | 34.11 | 35.40 |

| 持水孔隙度Water holding porosity/% | 40.12 | 40.53 |

| 气水比Gas water ratio | 0.86 | 0.87 |

| pH | 3.09 | 6.61 |

| 电导率EC/(mS·cm-1) | 0.98 | 0.99 |

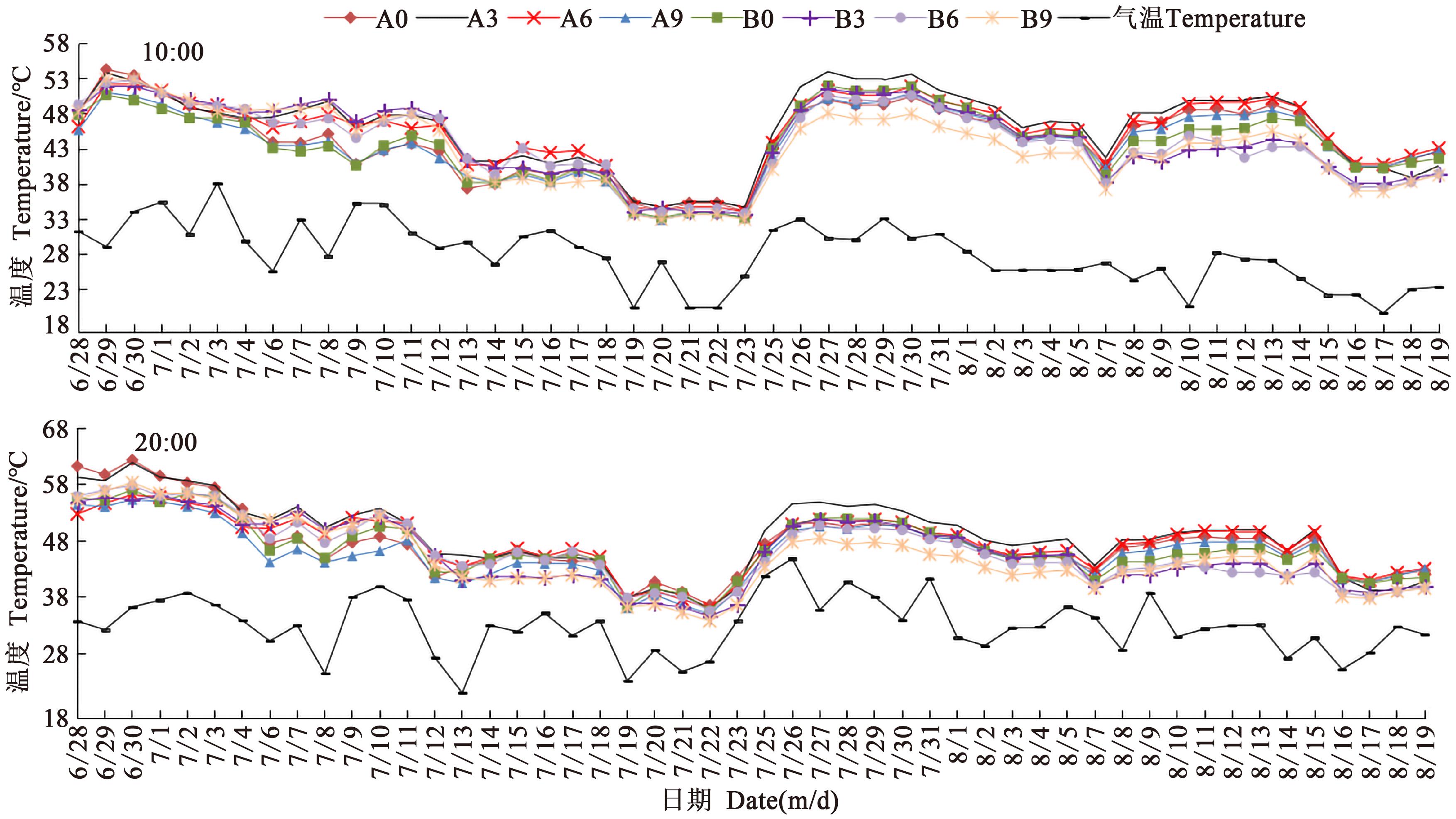

Fig. 1 Changes of heap temperature and temperature under different fermentation treatmentsNote: The dump was turned on 5 July, 24 July and 6 August, and the temperature was not determined.

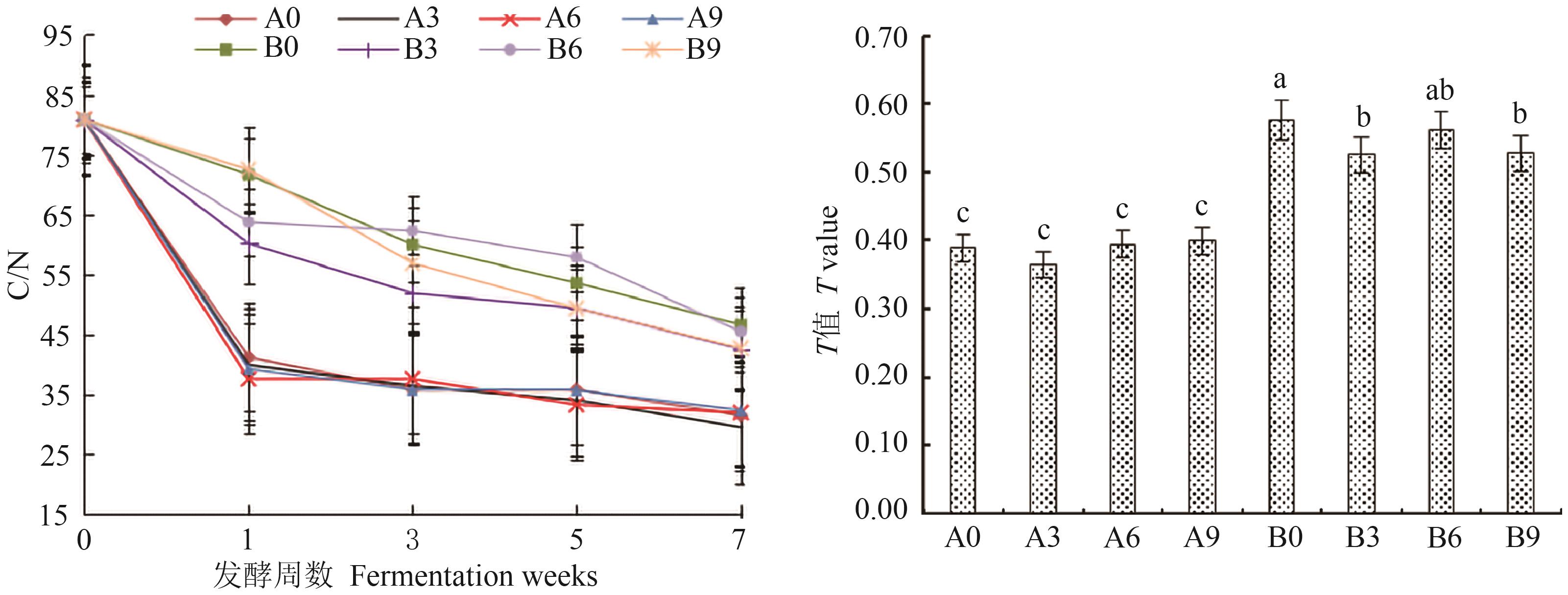

Fig. 4 C/N and T value under different fermentation treatmentsNote: Different lowercase latters indicate significant differenmes betwen different treatments at P<0.05 level.

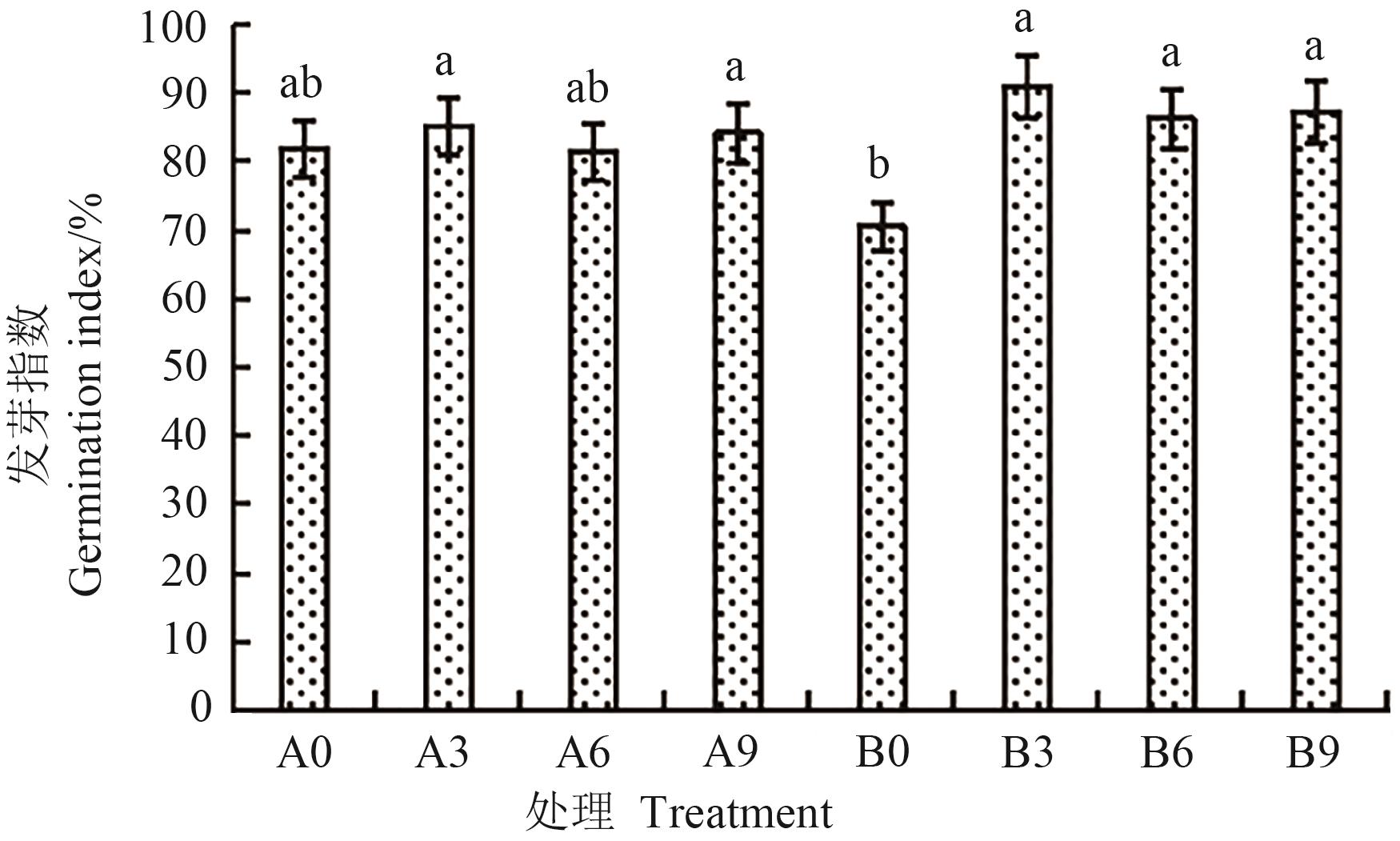

Fig. 5 Seed germination index of substrate extracts under different fermentation treatmentsNote: Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

| 元素 Element | A0 | A3 | A6 | A9 | B0 | B3 | B6 | B9 |

|---|---|---|---|---|---|---|---|---|

| 钼Mo/(mg·kg-1) | 8.11±0.11 a | 0.44±0.16 g | 1.14±0.08 f | 4.01±0.18 c | 2.56±0.17 e | 3.15±0.17 d | 6.99±0.22 b | 2.59±0.11 e |

| 锌Zn/(mg·kg-1) | 85.25±0.25 a | 51.44±0.18 d | 42.35±0.12 g | 59.93±0.20 c | 48.59±0.24 e | 60.44±0.16 b | 59.81±0.10 c | 46.03±0.01 f |

| 银Ag/(mg·kg-1) | 0.19±0.01 d | 0.01±0.00 e | 0.01±0.00 e | 0.29±0.01 b | 0.02±0.00 e | 0.01±0.00 e | 0.25±0.01 c | 1.79±0.05 a |

| 镍Ni/(mg·kg-1) | 14.43±0.15 f | 10.55±0.15 g | 23.07±0.09 b | 26.78±0.15 a | 20.49±0.15 e | 21.93±0.23 c | 21.41±0.22 d | 20.69±0.21 e |

| 铅Pb/(mg·kg-1) | 11.48±0.22 a | 6.82±0.18 d | 5.65±0.17 f | 9.57±0.12 b | 6.49±0.09 e | 6.54±0.16 e | 7.52±0.11 c | 4.22±0.12 g |

| 钠Na/(mg·L-1) | 80.53±2.31 g | 117.94±2.31 d | 100.57±2.31 e | 89.88±2.31 f | 162.02±2.31 c | 164.70±2.31 bc | 167.37±0.00 b | 188.74±2.31 a |

| 氯Cl/(mg·L-1) | 114.15±0.71 g | 155.27±0.71 e | 148.89±0.71 f | 108.24±0.82 h | 983.38±1.88 c | 894.76±1.42 d | 988.35±1.42 b | 1 033.48±1.08 a |

| 钒V/ (mg·kg-1) | 20.53±0.12 a | 13.34±0.14 c | 11.42±0.11 e | 17.88±0.18 b | 10.27±0.25 f | 12.73±0.23 d | 10.56±0.17 f | 6.78±0.19 g |

| 铬Cr/(mg·kg-1) | 23.95±0.11 b | 15.32±0.13 f | 14.47±0.09 g | 21.81±0.19 c | 17.11±0.23 e | 27.82±0.13 a | 20.81±0.21 d | 13.72±0.19 h |

| 钴Co/(mg·kg-1) | 3.25±0.23 a | 1.89±0.12 e | 1.78±0.07 e | 2.86±0.09 b | 1.97±0.12 de | 2.33±0.08 c | 2.16±0.13 cd | 1.47±0.1 f |

| 砷As/(mg·kg-1) | 5.57±0.33 d | 0.67±0.11 g | 0.58±0.05 g | 6.39±0.07 c | 1.12±0.07 f | 7.08±0.15 b | 8.87±0.31 a | 4.39±0.13 e |

| 汞Hg/(mg·kg-1) | 0.30±0.10 a | 0.17±0.03 b | 0.16±0.00 b | 0.14±0.01 b | 0.14±0.00 b | 0.14±0.00 b | 0.06±0.00 c | 0.04±0.00 c |

| 镉Cd/(mg·kg-1) | 0.260±0.018 a | 0.001±0.001 f | 0.001±0.001 f | 0.096±0.002 c | 0.031±0.005 d | 0.018±0.008 e | 0.177±0.002 b | 0.003±0.002 f |

| 铜Cu/(mg·kg-1) | 16.43±0.14 b | 11.54±0.17 f | 10.47±0.12 g | 15.30±0.14 c | 13.90±0.05 e | 16.52±0.17 b | 20.91±0.13 a | 14.37±0.21 d |

Table 5 Contents of heavy metals and potentially toxic elements in walnut leaf substrate

| 元素 Element | A0 | A3 | A6 | A9 | B0 | B3 | B6 | B9 |

|---|---|---|---|---|---|---|---|---|

| 钼Mo/(mg·kg-1) | 8.11±0.11 a | 0.44±0.16 g | 1.14±0.08 f | 4.01±0.18 c | 2.56±0.17 e | 3.15±0.17 d | 6.99±0.22 b | 2.59±0.11 e |

| 锌Zn/(mg·kg-1) | 85.25±0.25 a | 51.44±0.18 d | 42.35±0.12 g | 59.93±0.20 c | 48.59±0.24 e | 60.44±0.16 b | 59.81±0.10 c | 46.03±0.01 f |

| 银Ag/(mg·kg-1) | 0.19±0.01 d | 0.01±0.00 e | 0.01±0.00 e | 0.29±0.01 b | 0.02±0.00 e | 0.01±0.00 e | 0.25±0.01 c | 1.79±0.05 a |

| 镍Ni/(mg·kg-1) | 14.43±0.15 f | 10.55±0.15 g | 23.07±0.09 b | 26.78±0.15 a | 20.49±0.15 e | 21.93±0.23 c | 21.41±0.22 d | 20.69±0.21 e |

| 铅Pb/(mg·kg-1) | 11.48±0.22 a | 6.82±0.18 d | 5.65±0.17 f | 9.57±0.12 b | 6.49±0.09 e | 6.54±0.16 e | 7.52±0.11 c | 4.22±0.12 g |

| 钠Na/(mg·L-1) | 80.53±2.31 g | 117.94±2.31 d | 100.57±2.31 e | 89.88±2.31 f | 162.02±2.31 c | 164.70±2.31 bc | 167.37±0.00 b | 188.74±2.31 a |

| 氯Cl/(mg·L-1) | 114.15±0.71 g | 155.27±0.71 e | 148.89±0.71 f | 108.24±0.82 h | 983.38±1.88 c | 894.76±1.42 d | 988.35±1.42 b | 1 033.48±1.08 a |

| 钒V/ (mg·kg-1) | 20.53±0.12 a | 13.34±0.14 c | 11.42±0.11 e | 17.88±0.18 b | 10.27±0.25 f | 12.73±0.23 d | 10.56±0.17 f | 6.78±0.19 g |

| 铬Cr/(mg·kg-1) | 23.95±0.11 b | 15.32±0.13 f | 14.47±0.09 g | 21.81±0.19 c | 17.11±0.23 e | 27.82±0.13 a | 20.81±0.21 d | 13.72±0.19 h |

| 钴Co/(mg·kg-1) | 3.25±0.23 a | 1.89±0.12 e | 1.78±0.07 e | 2.86±0.09 b | 1.97±0.12 de | 2.33±0.08 c | 2.16±0.13 cd | 1.47±0.1 f |

| 砷As/(mg·kg-1) | 5.57±0.33 d | 0.67±0.11 g | 0.58±0.05 g | 6.39±0.07 c | 1.12±0.07 f | 7.08±0.15 b | 8.87±0.31 a | 4.39±0.13 e |

| 汞Hg/(mg·kg-1) | 0.30±0.10 a | 0.17±0.03 b | 0.16±0.00 b | 0.14±0.01 b | 0.14±0.00 b | 0.14±0.00 b | 0.06±0.00 c | 0.04±0.00 c |

| 镉Cd/(mg·kg-1) | 0.260±0.018 a | 0.001±0.001 f | 0.001±0.001 f | 0.096±0.002 c | 0.031±0.005 d | 0.018±0.008 e | 0.177±0.002 b | 0.003±0.002 f |

| 铜Cu/(mg·kg-1) | 16.43±0.14 b | 11.54±0.17 f | 10.47±0.12 g | 15.30±0.14 c | 13.90±0.05 e | 16.52±0.17 b | 20.91±0.13 a | 14.37±0.21 d |

| 1 | 李源,马文强,朱占江,等.新疆核桃产业发展现状及对策建议[J].农学学报,2019,9(7):80-86. |

| LI Y, MA W Q, ZHU Z J, et al.. Xinjiang walnut industry: the development status and countermeasures [J]. J. Agric., 2019, 9(7):80-86. | |

| 2 | 胡东宇,高健,黄力平,等.南疆四地州核桃产业现状与发展思路[J].北方园艺,2021(13):148-154. |

| HU D Y, GAO J, HUANG L P, et al.. Current situation and development idea of walnut industry in four prefectures of Southern Xinjiang [J]. North Hortic., 2021(13):148-154. | |

| 3 | 柴艳芳.碱预处理对大花蕙兰基质松树皮发酵进程的影响[D].北京:北京林业大学,2014. |

| CHAI Y F. Effect of alkali pretreatment on Cymbidium matrix—pink bark fermentation process [D]. Beijing: Beijing Forestry University, 2014. | |

| 4 | 郭程程.酸化处理对玉木耳菌糠腐熟过程的影响及水稻育苗基质研制[D].长春:吉林农业大学,2018. |

| GUO C C. Effect of sulfuric acid pretreatment on the chemical properties and decay process during the composting process of white fungus chaff and preparation of rice seedling substrate [D]. Changchun: Jilin Agricultural University, 2018. | |

| 5 | 姚文英.南疆低成本复合基质的研制及育苗效果研究[D].阿拉尔:塔里木大学,2020. |

| YAO W Y. The study of the development and application effect of walnut leaf substrate [D]. Alar: Tarim University, 2020. | |

| 6 | 陈广银,王德汉,吴艳,等.石灰预处理对树叶堆肥过程中养分转化的影响[J].生态环境,2007(1):77-82. |

| CHEN G Y, WANG D H, WU Y, et al.. Effect of lime-pretreatment on nutrient transformation of leaves compost [J]. Ecol. Environ. Sci., 2007(1):77-82. | |

| 7 | 曾琼,刘德春,刘勇.植物角质层蜡质的化学组成研究综述[J].生态学报,2013,33(17):5133-5140. |

| ZENG Q, LIU D C, LIU Y. The overview and prospect of chemical composition of plant cuticular wax [J]. Acta Ecol. Sin., 2013, 33(17):5133-5140. | |

| 8 | 张璐.园林绿化废弃物堆肥化的过程控制及其产品改良与应用研究[D].北京:北京林业大学,2015. |

| ZHANG L. The process control of green waste composting and the improvement and application of compost product [D]. Beijing: Beijing Forestry University, 2015. | |

| 9 | 王艳壮,姚晓杰,李莹杰,等.核桃树叶基质化的酸碱前处理方式探究[J].农业灾害研究,2022,12(6):10-12. |

| WANG Y Z, YAO X J, LI Y J, et al.. Exploration of acid and alkaline pre-treatment methods for basalization of walnut leaves [J]. J. Agric. Catastrophol., 2022, 12(6):10-12 | |

| 10 | 王应梅,申耀东,杨宗贤,等.有机发酵基质理化性质变化及对甜瓜出苗的影响[J].塔里木大学学报,2022,34(3):53-60. |

| WANG Y M, SHEN Y D, YANG Z X, et al.. Effects of organic fermentation substrates on the emergence of melon seedlings and change of physicochemical properties [J]. J. Tarim Univ., 2022, 34(3):53-60. | |

| 11 | 环境保护部. 固体废物 有机质的测定 灼烧减量法: [S].北京:中国标准出版社,2015. |

| 12 | 白永娟.菇渣腐熟发酵条件及其在蔬菜育苗中的应用效果研究[D].杨凌:西北农林科技大学,2016. |

| BAI Y J. The conditions of mushroom composting fermentation and seedling effects of composting substrates in vegetables [D]. Yangling: Northwest A&F University, 2016. | |

| 13 | 邓聚龙.灰色系统基本方法[M].武汉:华中科技大学出版社,2001:174. |

| DENG J L. Basic Method of Grey System [M]. Wuhan: Huazhong University of Science & Technology Press, 2001:174. | |

| 14 | 杨泽敏,王维金,卢碧林.灰色关联分析在稻米品质综合评价上的应用[J].中国粮油学报,2003,18(3):4-6. |

| YANG Z M, WANG W J, LU B L. Application of gray relational analysis in comprehensive evaluation of quality of rice [J]. J. Chin. Cereals Oils Assoc., 2003, 18(3):4-6. | |

| 15 | 农业农村部. 蔬菜育苗基质: [S].北京:中国农业出版社,2012. |

| 16 | 许燕,陈如凯,张木清.嗜热侧孢霉生物学特性及其液体发酵研究[J].福建农林大学学报(自然科学版),2008,37(1):99-104. |

| XU Y, CHEN R K, ZHANG M Q. Study on liquid fermentation and biological characteristics of Sporotrichum thermophile [J]. J. Fujian Agric. For. Univ., 2008, 37(1):99-104. | |

| 17 | 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 绿化用有机基质: [S].北京:中国标准出版社,2017. |

| 18 | ZUCCONI F, MONACO A, DEBERTOLDI M. Biological evaluation of compost maturity [J]. Biocycle, 1981, 22(4):27-29. |

| 19 | 冯海萍,杨志刚,杨冬艳,等.枸杞枝条基质化发酵工艺及参数优化[J].农业工程学报,2015,31(5):252-258. |

| FENG H P, YANG Z G, YANG D Y, et al.. Parameter optimization of fermented substrate from wolfberry shoots [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(5):252-258. | |

| 20 | 白永娟,徐炜南,常晓晓,等.不同碳氮比及氮源对菇渣发酵的影响[J].浙江大学学报(农业与生命科学版),2016,42(6):760-768. |

| BAI Y J, XU W N, CHANG X X, et al.. Effects of carbon-to-nitrogen ratios and nitrogen sources on composting of mushroom residue [J]. J. Zhejiang. Univ. (Agric. Life Sci.), 2016, 42(6):760-768. | |

| 21 | 姚文英,张中荣,黄亚星,等.不同发酵菌剂对树叶堆腐的效果[J].北方园艺,2019(5):26-31. |

| YAO W Y, ZHANG Z R, HUANG Y X, et al.. Effects of different fermentation bacteria on leaf compost [J]. North Hortic., 2019 (5):26-31. | |

| 22 | 陈汉才,李桂花,廖森泰,等.农业废弃物无害化处理技术规范[J].广东农业科学,2010,37(8):222-239. |

| 23 | ZHANG S, WEI Z, ZHAO M, et al.. Influence of malonic acid and manganese dioxide on humic substance formation and inhibition of CO2 release during composting [J/OL]. Bioresour. Technol., 2020, 318(2):124075 [2022-03-02]. . |

| 24 | ZHOU Y, SELVAM A, WONG J W C. Evaluation of humic substances during co-composting of food waste, sawdust and Chinese medicinal herbal residues [J]. Bioresour. Technol., 2014, 168(9):229-234. |

| 25 | 马怀良,许修宏.接种菌剂对鸡粪堆肥的影响[J].中国土壤与肥料,2009(5):61-63. |

| MA H L, XU X H. Effect of microbial inoculants on composting of chicken manure [J]. Soil Fert. Sci. Chin., 2009(5):61-63. | |

| 26 | 蒋志伟.赤泥对堆肥中木质纤维素降解和腐殖质形成及功能微生物群落演替的影响[D].南宁:广西大学,2020. |

| JIANG Z W. Effects of red mud on the degradation of humus formation and succession of functional microbial communies during composting [D]. Nanning: Guangxi University, 2020. | |

| 27 | 张陆,曹玉博,王惟帅,等.鸡粪添加对蔬菜废弃物堆肥腐殖化过程的影响[J].中国生态农业学报,2022,30(2):258-267. |

| ZHANG L, CAO Y B, WANG W S, et al.. Effect of chicken manure addition on humification of vegetable waste in composting process [J]. Chin. J. Eco-Agric., 2022, 30(2):258-267. | |

| 28 | 张阅,王磊,陈金海.物料预处理对堆肥减量化、腐殖化和稳定化的影响及其微生物机制[J].工业微生物,2015,45(1):7-14. |

| ZHANG Y, WANG L, CHEN J H. Effect of windrow pretreatment on reduction and humification during composting and its microbial mechanism [J]. Ind. Microbiol., 2015, 45(1):7-14. | |

| 29 | 吴阳,徐乐中,梅娟.C/N调控对园林绿化废弃物堆肥效果的影响[J].安全与环境工程,2016,23(1):64-69. |

| WU Y, XU L Z, MEI J. Effect of C/N regulation on the performance of composting of green plant waste [J]. Saf. Environ. Eng., 2016, 23(1):64-69. | |

| 30 | 吴梦婷,梅娟,苏良湖,等.硫酸亚铁和过磷酸钙对牛粪秸秆混合堆肥氮损失和腐殖化的影响[J].生态与农村环境学报,2020,36(10):1353-1361. |

| WU M T, MEI J, SU L H, et al.. Effects of ferrous sulfate and calcium superphosphate on nitrogen loss and humification during composting of cattle manure with straw [J]. J. Ecol. Rur. Environ, 2020, 36(10):1353-1361. | |

| 31 | 陈广银,王德汉,吴艳,等.落叶堆肥过程中有机物的动态变化[J].华南农业大学学报,2007,28(02):1-4. |

| CHEN G Y, WANG D H, WU Y, et al.. Dynamic transformation of organic matter during thermophilic composting of litter [J]. J. South Chin. Agric. Univ., 2007, 28(2):1-4. | |

| 32 | 孙桂阳,张国言,董元杰.不同来源农业废弃物堆肥进程与产品肥效研究[J].水土保持学报,2021,35(4):349-360. |

| SUN G Y, ZHANG G Y, DONG Y J. Composting process of agricultural wastes from different sources and fertilizer efficiency of theie products [J]. J. Soil Water Conser., 2021, 35(4):349-360. | |

| 33 | MOREL T L, COLIN F, GERMON J C, et al.. Methods for the Evaluation of the Matutity of Municipal Refuse Compost [M]. London: El Sevier Applied Science publishers, 1985:56-72. |

| [1] | Shegang SHAO, Ting LI, Yong LIU, Lanwen LIN, Dong ZHANG, Dong NI, Junjie LI, Li’an ZHU. Effects of Exogenous Promoting Bacteria Agent on Decomposition Characteristics and Microbial Community Structure of Rice Straw [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 166-177. |

| [2] | Dongmeng ZHANG, Dongping YAO, Jun WU, Qiuhong LUO, Wen ZHUANG, Xionglun LIU, Qiyun DENG, Bin BAI. Effect of Natural Low Temperature on Cooking and Eating Quality of Rice During Grain Filling Stage [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 144-153. |

| [3] | Zhongxiu RAO, Jimin SUN, Na ZHANG, Longtao LI, Chunhua DONG, Zengping YANG, Fengqiu HUANG. Impacts from Adding Artemisia argyi Straw into Substrates on Growth and Quality of Pleurotus ostreatus [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 208-215. |

| [4] | Lifang ZHANG, Zhiyuan LI, Yuxiang LIU, Hongli ZHANG, Yong QIN. Comprehensive Evaluation of Different Composite Substrates on Growth Condition of Coriandrum sativum L. [J]. Journal of Agricultural Science and Technology, 2023, 25(5): 204-214. |

| [5] | Chunlin CHEN, Linyang WANG, Mengwei SHAN, Tiantian PEI, Jiqing WANG, Huaijuan XIAO, Juanqi LI, Meng LI, Qingjie DU. Effects of Fermented Peanut Shell and Cow Dung Instead of Peat Substrate on Tomato Seedling [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 205-214. |

| [6] | Kemeng AN, Lixin ZHAO, Zonglu YAO, Jiadong YU, Zaixing LI, Yali HUANG, Yi LIANG, Ruixia SHEN. Research Progress of High-value Utilization of Straw to Synthesize Medium-chain Fatty Acids [J]. Journal of Agricultural Science and Technology, 2023, 25(3): 198-211. |

| [7] | Qian HU, Yining WANG, Pengfei SHEN, Yaqian LI, Yang YANG, Yancheng WANG, Wenxiu JI, Weiwei DONG. Fermentation Products Analysis of Producing β-glucosidase Endophytic Bacteria in Martianus dermestoides Transformated to Ginsenoside and Its Anti-tumor Activity [J]. Journal of Agricultural Science and Technology, 2023, 25(2): 119-127. |

| [8] | Hangfan GUO, Ping WANG, Ying WANG. Inhibitory Effect of Solanum nigrum L. Extracts on Escherichia coli and Enterococcus faecalis and Biofilm Formation [J]. Journal of Agricultural Science and Technology, 2023, 25(10): 152-164. |

| [9] | Li LIU, Zhongping DU, Yi LI, Laisheng CHEN, Rui HAN. Effect of NaOH Pretreatment on Anaerobic Fermentation Characteristics of Hulless Barley Straw [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 192-200. |

| [10] | Jinzhi MA, Zhiping ZHU, Lianshui LU, Wanqin ZHANG. Effect of Ventilation Rate on Treatment of Meat Duck Manure by Ectopic Fermentation System [J]. Journal of Agricultural Science and Technology, 2022, 24(3): 210-217. |

| [11] | JIAO Jing, ZHENG Yong, LI Zunxiang, HUANG Xiaohong, DU Jihua, ZHENG Jin. JIAO Jing1,2, ZHENG Yong3*, LI Zunxiang1, HUANG Xiaohong1, DU Jihua1, ZHENG Jin1 [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 87-95. |

| [12] | LI Baoshi, LIU Wenke, WANG Qi, ZHA Lingyan, ZHANG Yubin, ZHOU Chengbo, SHAO Mingjie. Influences of DMPP on the Cucumber Yield and Root Zone Greenhouse Gas Emission under Different Cultivation Methods [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 184-192. |

| [13] | XIA Hongze, HUANG Wenzhi, ZHANG Linlin, ZHANG Xiaohan, CUI Zhanhong, LIU Shujie. Influences of Oat Hay and Alfalfa Hay Combination with Different Grading Indexes on Rumen Fermentation of Yak in Vitro [J]. Journal of Agricultural Science and Technology, 2021, 23(7): 199-201. |

| [14] | HUANG Qingyang, JIANG Chao, YU Yuanchun, XIE Zubin. Effects of Different Straw Biochar Substrate on the Physiological Properties of Cosmos bipinnatus [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 147-153. |

| [15] | ZHOU Wanlai, YANG Rui, ZHANG Dongdong, LIN Wei, CHEN Xuejiao, WANG Hong, LI Jie, QI Zhiyong. Problems and Countermeasures in Substrate Utilization of Spent Mushroom Substrates [J]. Journal of Agricultural Science and Technology, 2021, 23(10): 117-123. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号