Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (2): 238-249.DOI: 10.13304/j.nykjdb.2023.0362

• BIO-MANUFACTURING & RESOURCE AND ECOLOGY • Previous Articles

Yilong DENG1( ), Jianan WANG1, Shaolong GU2, Xiaoquan ZHANG1, Xiaohui MIAO3, Shoujie SHI2, Weidong DUAN3(

), Jianan WANG1, Shaolong GU2, Xiaoquan ZHANG1, Xiaohui MIAO3, Shoujie SHI2, Weidong DUAN3( )

)

Received:2023-05-21

Accepted:2023-07-28

Online:2025-02-15

Published:2025-02-14

Contact:

Weidong DUAN

邓奕龙1( ), 王建安1, 顾少龙2, 张小全1, 苗晓辉3, 施守杰2, 段卫东3(

), 王建安1, 顾少龙2, 张小全1, 苗晓辉3, 施守杰2, 段卫东3( )

)

通讯作者:

段卫东

作者简介:邓奕龙 E-mail:dyl19980321@gmail.com;

基金资助:CLC Number:

Yilong DENG, Jianan WANG, Shaolong GU, Xiaoquan ZHANG, Xiaohui MIAO, Shoujie SHI, Weidong DUAN. Effect of Variable Temperature During Yellowing Stage on Synergistic Relationship Between Color Parameters and Pigment Contents of Upper leaves[J]. Journal of Agricultural Science and Technology, 2025, 27(2): 238-249.

邓奕龙, 王建安, 顾少龙, 张小全, 苗晓辉, 施守杰, 段卫东. 变黄期变温烘烤对上部叶颜色参数与色素含量协同关系的影响[J]. 中国农业科技导报, 2025, 27(2): 238-249.

| 指标Index | 处理Treatment | 烘烤时间Curing time/h | 烤后烟叶 Cured tobacco leaves | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 36 | 48 | 60 | 72 | 84 | 96 | |||

| L | CK | 50.77±0.56 a | 57.64±0.60 b | 57.98±1.83 c | 68.11±1.65 ab | 66.58±0.91 b | 67.80±1.17 a | 65.75±1.98 a | 51.43±1.37 b |

| T1 | 53.80±0.72 a | 64.90±0.58 a | 70.11±1.49 a | 70.24±0.22 a | 70.29±0.83 a | 69.03±0.26 a | 65.99±1.05 a | 58.36±0.52 a | |

| T2 | 51.43±2.27 a | 57.09±0.16 b | 62.41±3.08 b | 67.17±2.47 b | 67.00±0.27 b | 65.45±2.10 b | 55.75±2.72 b | 48.30±2.02 c | |

| a | CK | -8.55±0.20 a | -3.37±0.30 ab | -1.86±0.65 b | 5.06±0.67 a | 5.56±0.16 b | 7.63±0.70 a | 8.51±0.09 a | 12.50±0.25 b |

| T1 | -7.65±0.55 a | -1.58±1.87 a | -1.02±0.14 b | 4.87±0.72 a | 7.20±0.94 a | 7.61±0.39 a | 7.82±0.62 a | 10.63±0.10 c | |

| T2 | -8.04±0.98 a | -4.38±0.09 b | 3.53±1.04 a | 5.39±0.47 a | 5.81±0.03 b | 5.98±0.55 b | 7.39±1.85 a | 13.83±0.16 a | |

| b | CK | 38.82±0.65 a | 53.13±0.97 b | 53.47±3.71 a | 58.97±1.81 b | 59.25±0.07 ab | 55.86±1.67 a | 53.72±1.22 a | 48.24±1.88 ab |

| T1 | 38.96±2.99 a | 55.72±1.24 a | 56.53±2.98 a | 62.71±1.53 a | 60.87±1.46 a | 56.15±3.37 a | 56.12±0.77 a | 51.80±1.12 a | |

| T2 | 37.58±1.61 a | 47.93±0.16 c | 56.42±1.51 a | 59.05±0.96 b | 55.82±2.13 b | 55.59±1.94 a | 45.98±2.20 b | 45.66±3.24 b | |

Table 1 L, a and b value of flue-cured tobacco leaves during curing

| 指标Index | 处理Treatment | 烘烤时间Curing time/h | 烤后烟叶 Cured tobacco leaves | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 36 | 48 | 60 | 72 | 84 | 96 | |||

| L | CK | 50.77±0.56 a | 57.64±0.60 b | 57.98±1.83 c | 68.11±1.65 ab | 66.58±0.91 b | 67.80±1.17 a | 65.75±1.98 a | 51.43±1.37 b |

| T1 | 53.80±0.72 a | 64.90±0.58 a | 70.11±1.49 a | 70.24±0.22 a | 70.29±0.83 a | 69.03±0.26 a | 65.99±1.05 a | 58.36±0.52 a | |

| T2 | 51.43±2.27 a | 57.09±0.16 b | 62.41±3.08 b | 67.17±2.47 b | 67.00±0.27 b | 65.45±2.10 b | 55.75±2.72 b | 48.30±2.02 c | |

| a | CK | -8.55±0.20 a | -3.37±0.30 ab | -1.86±0.65 b | 5.06±0.67 a | 5.56±0.16 b | 7.63±0.70 a | 8.51±0.09 a | 12.50±0.25 b |

| T1 | -7.65±0.55 a | -1.58±1.87 a | -1.02±0.14 b | 4.87±0.72 a | 7.20±0.94 a | 7.61±0.39 a | 7.82±0.62 a | 10.63±0.10 c | |

| T2 | -8.04±0.98 a | -4.38±0.09 b | 3.53±1.04 a | 5.39±0.47 a | 5.81±0.03 b | 5.98±0.55 b | 7.39±1.85 a | 13.83±0.16 a | |

| b | CK | 38.82±0.65 a | 53.13±0.97 b | 53.47±3.71 a | 58.97±1.81 b | 59.25±0.07 ab | 55.86±1.67 a | 53.72±1.22 a | 48.24±1.88 ab |

| T1 | 38.96±2.99 a | 55.72±1.24 a | 56.53±2.98 a | 62.71±1.53 a | 60.87±1.46 a | 56.15±3.37 a | 56.12±0.77 a | 51.80±1.12 a | |

| T2 | 37.58±1.61 a | 47.93±0.16 c | 56.42±1.51 a | 59.05±0.96 b | 55.82±2.13 b | 55.59±1.94 a | 45.98±2.20 b | 45.66±3.24 b | |

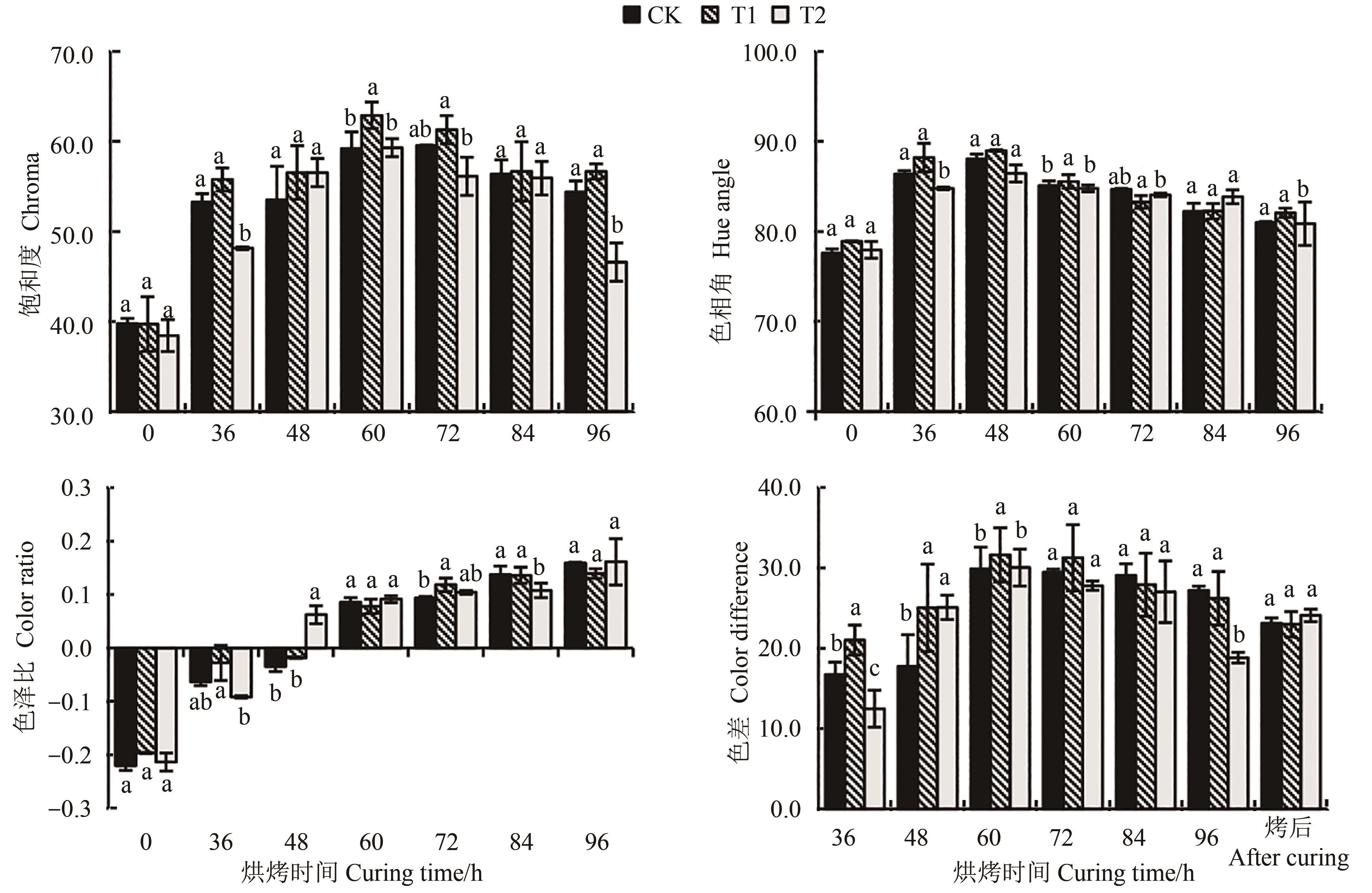

Fig. 4 C, h, H and ΔE of flue-cured tobacco leaves during curingNote: Different lowercase letters indicate significant differences between different treatments in same time at P<0.05 level.

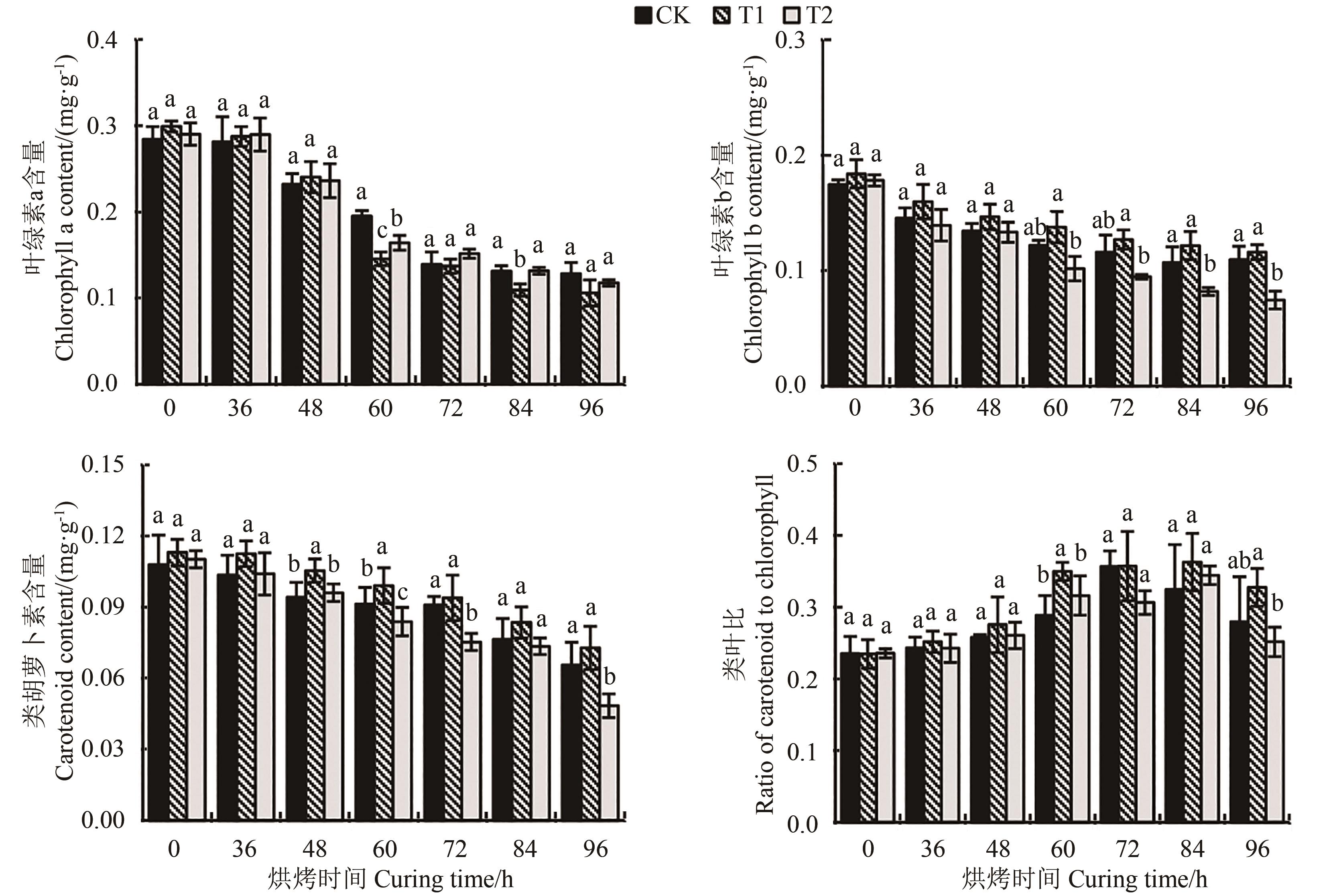

Fig. 5 Pigment contents of flue-cured tobacco leaves during curingNote: Different lowercase letters indicate significant differences between different treatments in same time at P<0.05 level.

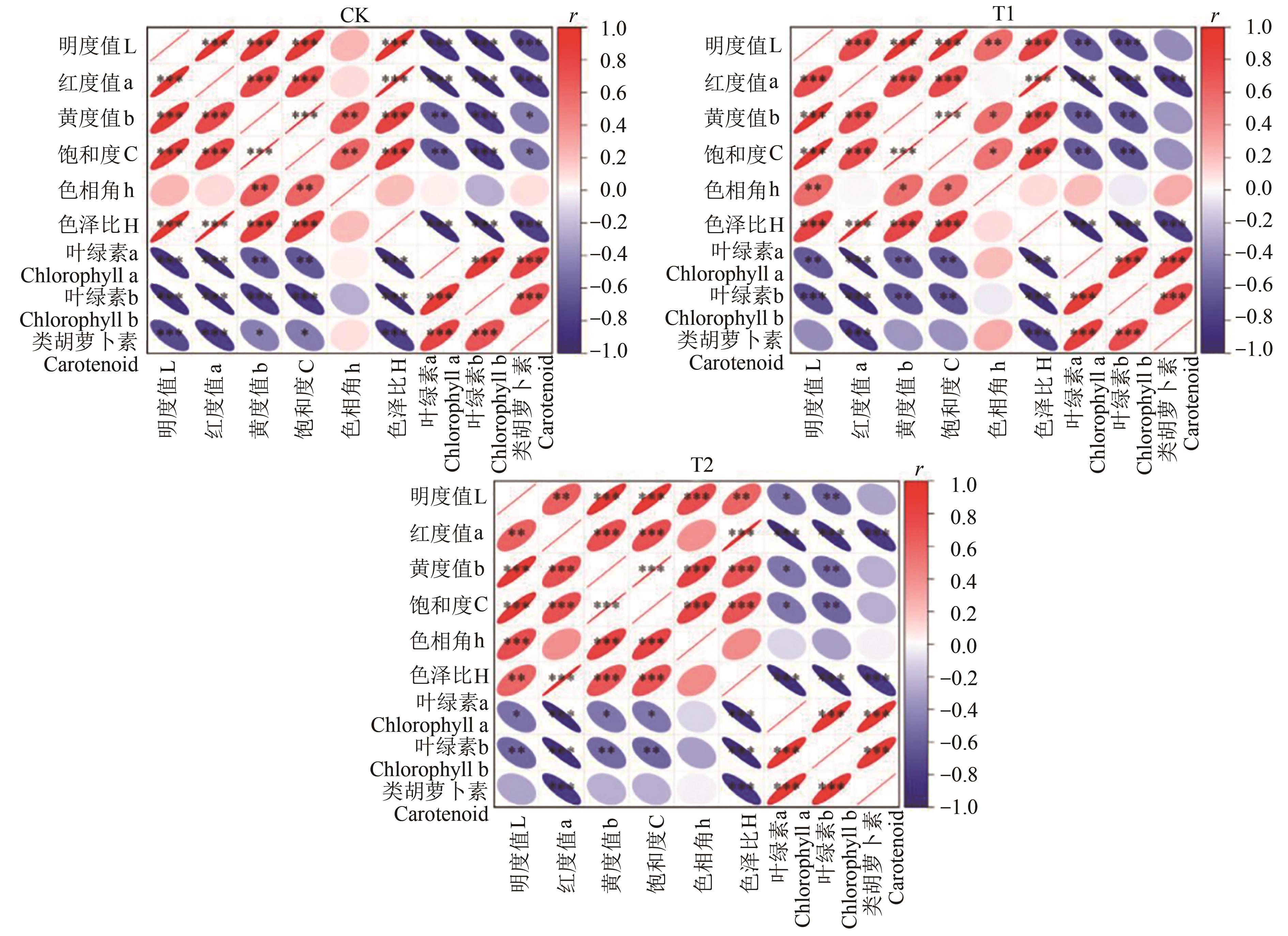

Fig. 6 Correlation of color parameters and pigment contents of flue-cured tobacco leaves during curingNote: *, ** and *** indicate significant correlation at P<0.05, P<0.01 and P<0.001 levels, respectively. The red ellipse indicates positive correlation, the blue ellipse indicates negative correlation, and the size of the ellipse area indicates the size of the correlation.

处理 Treatment | 指标 Index | 回归方程 Regression equation | R2 | F值 F value |

|---|---|---|---|---|

| CK | 叶绿素a Chlorophyll a | ŷ1=0.229-0.024x2+0.675x6 | 0.897 | 78.18** |

| 叶绿素b Chlorophyll b | ŷ2=0.134-0.176x6 | 0.872 | 130.00** | |

| 类胡萝卜素 Carotenoid | ŷ3=0.094-0.002x2 | 0.611 | 29.85** | |

| T1 | 叶绿素a Chlorophyll a | ŷ1=-0.158-0.013x2+0.005x5 | 0.931 | 122.08** |

| 叶绿素b Chlorophyll b | ŷ2=0.148-0.189x6 | 0.808 | 79.97** | |

| 类胡萝卜素Carotenoid | ŷ3=0.051-0.003x2+0.001x3 | 0.754 | 27.59** | |

| T2 | 叶绿素a Chlorophyll a | ŷ1=-0.349-0.013x2+0.007x5 | 0.903 | 83.58** |

| 叶绿素b Chlorophyll b | ŷ2=0.123-0.253x6 | 0.820 | 86.42** | |

| 类胡萝卜素Carotenoid | ŷ3=0.037-0.199x6+0.003x4-0.002x1 | 0.894 | 48.00** |

Table 2 Stepwise regression analysis of color parameters and pigment contents of flue-cured tobacco leaves during curing

处理 Treatment | 指标 Index | 回归方程 Regression equation | R2 | F值 F value |

|---|---|---|---|---|

| CK | 叶绿素a Chlorophyll a | ŷ1=0.229-0.024x2+0.675x6 | 0.897 | 78.18** |

| 叶绿素b Chlorophyll b | ŷ2=0.134-0.176x6 | 0.872 | 130.00** | |

| 类胡萝卜素 Carotenoid | ŷ3=0.094-0.002x2 | 0.611 | 29.85** | |

| T1 | 叶绿素a Chlorophyll a | ŷ1=-0.158-0.013x2+0.005x5 | 0.931 | 122.08** |

| 叶绿素b Chlorophyll b | ŷ2=0.148-0.189x6 | 0.808 | 79.97** | |

| 类胡萝卜素Carotenoid | ŷ3=0.051-0.003x2+0.001x3 | 0.754 | 27.59** | |

| T2 | 叶绿素a Chlorophyll a | ŷ1=-0.349-0.013x2+0.007x5 | 0.903 | 83.58** |

| 叶绿素b Chlorophyll b | ŷ2=0.123-0.253x6 | 0.820 | 86.42** | |

| 类胡萝卜素Carotenoid | ŷ3=0.037-0.199x6+0.003x4-0.002x1 | 0.894 | 48.00** |

处理 Treatment | 烟碱 Nicotine | 还原糖 Reducing sugar | 总糖 Total sugar | 总氮 Total nitrogen | 钾 Potassium | 氯 Chlorine | 淀粉 Starch |

|---|---|---|---|---|---|---|---|

| CK | 2.31±0.06 b | 26.40±0.37 b | 36.10±0.87 b | 2.21±0.15 b | 1.60±0.25 a | 0.28±0.07 a | 5.35±0.16 b |

| T1 | 2.02±0.10 b | 23.20±0.07 c | 29.90±0.17 c | 2.02±0.10 b | 1.38±0.10 a | 0.27±0.06 a | 4.65±0.09 c |

| T2 | 3.24±0.20 a | 27.10±0.07 a | 37.90±0.11 a | 2.72±0.05 a | 1.48±0.09 a | 0.23±0.02 a | 6.44±0.14 a |

Table 3 Chemical composition of flue-cured tobacco leaves by three kinds of technology

处理 Treatment | 烟碱 Nicotine | 还原糖 Reducing sugar | 总糖 Total sugar | 总氮 Total nitrogen | 钾 Potassium | 氯 Chlorine | 淀粉 Starch |

|---|---|---|---|---|---|---|---|

| CK | 2.31±0.06 b | 26.40±0.37 b | 36.10±0.87 b | 2.21±0.15 b | 1.60±0.25 a | 0.28±0.07 a | 5.35±0.16 b |

| T1 | 2.02±0.10 b | 23.20±0.07 c | 29.90±0.17 c | 2.02±0.10 b | 1.38±0.10 a | 0.27±0.06 a | 4.65±0.09 c |

| T2 | 3.24±0.20 a | 27.10±0.07 a | 37.90±0.11 a | 2.72±0.05 a | 1.48±0.09 a | 0.23±0.02 a | 6.44±0.14 a |

处理 Treatment | 成熟度 Maturity | 颜色 Color | 油分 Tar | 身份 Thickness | 结构 Structure | 色度 Tint | 挂灰杂色 Surface dusting | 含青 Green content |

|---|---|---|---|---|---|---|---|---|

| CK | 成熟 Mature | 橘黄色 Orange | 有+ Exist+ | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 无 None |

| T1 | 成熟 Mature | 橘黄色 Orange | 多 Much | 适中- Moderate- | 尚疏松 Slightly loose | 浓 Concentrated | 微有 Slightly exist | 无 None |

| T2 | 成熟 Mature | 红棕色 Reddish brown | 有 Exist | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 微有 Slightly exist |

Table 4 Appearance quality evaluation of flue-cured tobacco leaves by 3 kinds of technology

处理 Treatment | 成熟度 Maturity | 颜色 Color | 油分 Tar | 身份 Thickness | 结构 Structure | 色度 Tint | 挂灰杂色 Surface dusting | 含青 Green content |

|---|---|---|---|---|---|---|---|---|

| CK | 成熟 Mature | 橘黄色 Orange | 有+ Exist+ | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 无 None |

| T1 | 成熟 Mature | 橘黄色 Orange | 多 Much | 适中- Moderate- | 尚疏松 Slightly loose | 浓 Concentrated | 微有 Slightly exist | 无 None |

| T2 | 成熟 Mature | 红棕色 Reddish brown | 有 Exist | 稍厚 Slightly thick | 稍密 Slightly dense | 强 Strong | 有 Exist | 微有 Slightly exist |

| 1 | 张烨,王松峰,许锡祥,等.烟叶烘烤中不同区段叶片含水量、色素和酶活性变化[J].中国烟草科学,2018,39(6):66-72. |

| ZHANG Y, WANG S F, XU X X, et al.. Changes of water content, pigments and enzymes activities in tobacco leaves of different sections during flue-curing process [J]. Chin. Tob. Sci., 2018, 39(6):66-72. | |

| 2 | 李晓辉,甄焕菊,牛慧伟,等.不同烘烤工艺对红花大金元上部烟叶烘烤质量的影响[J].山东农业科学,2022,54(5):79-83. |

| LI X H, ZHEN H J, NIU H W, et al.. Effects of different curing processes on curing quality of upper leaves of tobacco Honghuadajinyuan [J]. Shandong Agric. Sci., 2022, 54(5):79-83. | |

| 3 | 过伟民,郑劲民,常乃杰,等.基于温湿度时序数据的烟叶烘烤工艺特征分析[J].中国烟草学报,2022,28(5):56-63. |

| GUO W M, ZHENG J M, CHANG N J, et al.. Analysis of flue-curing process characteristics based on temperature and humidity time series data [J]. Acta Tab. Sin., 2022, 28(5):56-63. | |

| 4 | 李昱霖,赵亚峰,徐志强,等.烤烟分状态变风机频率烘烤工艺参数优化[J].中南农业科技,2023,44(1):69-73. |

| 5 | 王爱华,王松峰,管志坤,等.烤烟密集烘烤过程中阶梯升温变黄生理生化特性研究[J].中国烟草科学,2012,33(1):69-73. |

| WANG A H, WANG S F, GUAN Z K, et al.. Physiology and biochemistry characters of step temperature yellowing during bulk curing process of tobacco leaves [J]. Chin. Tob. Sci., 2012, 33(1):69-73. | |

| 6 | 王鹏泽,来苗,陶陶,等.不同香型烤烟主要香味物质成分与香韵指标的关系研究[J].中国农业科技导报,2015,17(3):126-135. |

| WANG P Z, LAI M, TAO T, et al.. Relationships between main aroma constituents and aroma notes index of flue-cured tobacco leaves of different flavor styles [J]. J. Agric. Sci. Technol., 2015, 17(3):126-135. | |

| 7 | JIA J X, ZHANG M J, ZHAO J H, et al.. The effects of increasing the dry-bulb temperature during the stem-drying stage on the quality of upper leaves of flue-cured tobacco [J/OL]. Processes, 2023, 11(3):726 [2023-04-10]. . |

| 8 | WU S J, GUO Y S, JOAN H I, et al.. ITRAQ-based comparative proteomic analysis reveals high temperature accelerated leaf senescence of tobacco (Nicotiana tabacum L.) during flue-curing [J]. Genomics, 2020, 112(5):3075-3088. |

| 9 | 王建安,范艺宽,张同庆,等.密集烤房内置式生物质供热炉体的设计与试验[J].中国烟草学报,2021,27(4):36-44. |

| WANG J A, FAN Y K, ZHANG T Q, et al.. Design and test of biomass furnace in intensive baking room [J]. Acta Tab. Sin., 2021, 27(4):36-44. | |

| 10 | CHEN Z G, HUANG J R, PU H Y, et al.. The effects of temperature on starch molecular conformation and hydrogen bonding [J/OL]. Starch‐Stärke, 2022, 74(7-8):2100288 [2023-04-10]. . |

| 11 | ZHANG W J, DONG X L, LIN M S, et al.. Curing technology for improving the quality of upper tobacco leaves [J]. Asian J. Agric. Res., 2018, 10(11):68-74. |

| 12 | 王爱华,徐秀红,王松峰,等.变黄温度对烤烟烘烤过程中生理指标及烤后质量的影响[J].中国烟草学报,2008,14(1):27-31. |

| WANG A H, XU X H, WANG S F, et al.. Effect of temperature in yellowing stage on physiological indices and quality of flue-cured tobacco [J]. Acta Tab. Sin., 2008, 14(1):27-31. | |

| 13 | 任杰,王涛,饶智,等.不同变黄变筋温度对红花大金元香气物质含量的影响[J].中国烟草科学,2017,38(3):61-66. |

| REN J, WANG T, RAO Z, et al.. Effects of different leaf-yellowing and midrib-yellowing temperature on aroma constituents of Honghuadajinyuan [J]. Chin. Tob. Sci., 2017, 38(3):61-66. | |

| 14 | 高相彬,宗胜杰,孟智勇,等.变黄期温湿度对豫烟10号碳代谢及烤后品质的影响[J].西南农业学报,2019,32(10):2454-2458. |

| GAO X B, ZONG S J, MENG Z Y, et al.. Effect of temperature and humidity during yellowing stage on carbon metabolism and cured quality of Yuyan 10 [J]. Southwest China J. Agric. Sci., 2019, 32(10):2454-2458. | |

| 15 | 孟智勇,李建华,马浩波,等.烘烤工艺对豫中浓香型烤烟上六片烟叶品质的影响[J].河南农业科学,2021,50(10):154-162. |

| MENG Z Y, LI J H, MA H B, et al.. Effect of curing technology on the quality of upper six leaves of strong flavor type flue‑cured tobacco grown in central Henan [J]. J. Henan Agric. Sci., 2021, 50(10):154-162. | |

| 16 | 裴晓东,王涛,李帆,等.密集烘烤过程中烤烟上部叶颜色参数与主要化学成分变化[J].华北农学报,2012,27():218-222. |

| PEI X D, WANG T, LI F, et al.. Relationship between changes of color parameters and chemical components of upper flue-cured tobacco leaves during bulk-curing process [J]. Acta Agric. Boreal-Sin., 2012, 27(S1):218-222. | |

| 17 | 张佳佳,过伟民,段卫东,等.上6片烟叶烘烤过程中水分与颜色及化学成分的协同变化[J].烟草科技,2021,54(3):17-23, 57. |

| ZHANG J J, GUO W M, DUAN W D, et al.. Coordinated variations of moisture content, color and chemical components of top six upper leaves during flue-curing [J]. Tob. Sci. Technol., 2021, 54(3):17-23, 57. | |

| 18 | 贺帆,王涛,王梅,等.烘烤过程中烟叶颜色变化与主要化学成分的关系[J].中国烟草学报,2014,20(6):97-102. |

| HE F, WANG T, WANG M, et al.. Relationship between color changes and chemical components of flue-cured tobacco leaves during curing [J]. Acta Tab. Sin., 2014, 20(6):97-102. | |

| 19 | 王学奎,黄见良.植物生理生化实验原理和技术[M].2版.北京:高等教育出版社,2014: 1-324. |

| 20 | 国家烟草专卖局. 烟草及烟草制品总植物碱的测定连续流动法: [S].北京:中国标准出版社,2002. |

| 21 | 国家烟草专卖局. 烟草及烟草制品总氮的测定连续流动法: [S].北京:中国标准出版社,2002. |

| 22 | 国家烟草专卖局. 烟草及烟草制品水溶性糖的测定连续流动法: [S].北京:中国标准出版社,2002. |

| 23 | 国家烟草专卖局. 烟草及烟草制品钾的测定连续流动法: [S].北京:中国标准出版社,2007. |

| 24 | 国家烟草专卖局. 烟草及烟草制品氯的测定连续流动法: [S].北京:中国标准出版社,2011. |

| 25 | 国家烟草专卖局. 烟草及烟草制品淀粉的测定连续流动法: [S].北京:中国标准出版社,2013. |

| 26 | 国家烟草专卖局. 烤烟: [S].北京:中国标准出版社,1992. |

| 27 | 国家烟草专卖局. 烤烟-烟叶质量风格特色感官评价方法: [S].北京:中国标准出版社,2015. |

| 28 | LIU A M, YUAN K L, XU H Q, et al.. Proteomic and metabolomic revealed differences in the distribution and synthesis mechanism of aroma precursors in Yunyan 87 tobacco leaf, stem, and root at the seedling stage [J]. ACS Omega, 2022, 7(37):33295-33306. |

| 29 | 丁根胜,张庆明,巴金莎,等.烟叶颜色色度学指标与烤烟品质的关系分析[J].中国烟草科学,2011,32(4):14-18. |

| DING G S, ZHANG Q M, BA J S, et al.. Analysis of relationship between colorimetry indices and quality of flue-cured tobacco [J]. Chin. Tob. Sci., 2011, 32(4):14-18. | |

| 30 | TANG Z X, CHEN L L, CHEN Z B, et al.. Climatic factors determine the yield and quality of Honghe flue-cured tobacco [J/OL]. Sci. Rep., 2020, 10(1):19868 [2023-04-10]. . |

| 31 | 武圣江,周义和,宋朝鹏,等.密集烘烤过程中烤烟上部叶质地和色度变化研究[J].中国烟草学报,2010,16(5):72-77. |

| WU S J, ZHOU Y H, SONG Z P, et al.. Study on texture and col or change in upper leaves during bulk flue-curing [J]. Acta Tab. Sin., 2010, 16(5):72-77. | |

| 32 | 孟可爱,聂荣邦,肖春生,等.密集烘烤过程中烟叶水分和色素含量的动态变化[J].湖南农业大学学报(自然科学版),2006, 32(2):144-148. |

| MENG K A, NIE R B, XIAO C S, et al.. Changes of pigment and moisture content in cured tobacco leaves during bulk curing process [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2006, 32(2):144-148. | |

| 33 | 杨立均,宫长荣,马京民.烘烤过程中烟叶色素的降解及与化学成分的相关分析[J].中国烟草科学,2002(2):5-7. |

| YANG L J, GONG C R, MA J M, et al.. Degradation of pigment in tobacco leaf during flue-curing process and relative analysis with chemical compositions [J]. Chin. Tob. Sci., 2002(2):5-7. | |

| 34 | 杨虹琦,周冀衡,杨述元,等.不同产区烤烟中主要潜香型物质对评吸质量的影响研究[J].湖南农业大学学报(自然科学版),2005, 31(1):11-14. |

| YANG H Q, ZHOU J H, YANG S Y, et al.. Effect on chiefly latent fragrant substance on panel test flue-cured tobacco from different producing area [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2005, 31(1):11-14. | |

| 35 | ZONG J J, HE X, LIN Z L, et al.. Effect of two drying methods on chemical transformations in flue-cured tobacco [J]. Dry. Technol., 2022, 40(1):188-196. |

| 36 | LI C, JI J, WANG G, et al.. Over-expression of LcPDS, LcZDS and LcCRTISO genes from wolfberry for carotenoid biosynthesis, enhanced carotenoid accumulation, and salt tolerance in tobacco [J/OL]. Front. Plant Sci., 2020, 11:119 [2023-04-10]. . |

| 37 | 董淑君,黄明迪,王耀锋,等.密集烤房与普通烤房烘烤中烟叶色素和多酚含量的变化分析[J].中国烟草科学,2015,36(1):90-95. |

| DONG S J, HUANG M D, WANG Y F, et al.. Change difference of pigment and polyphenol contents between bulk-curing barn and traditional flue-curing barn during curing process [J]. Chin. Tob. Sci., 2015, 36(1):90-95. | |

| 38 | ZHANG H H, XU Z S, GUO K W, et al.. Toxic effects of heavy metal Cd and Zn on chlorophyll, carotenoid metabolism and photosynthetic function in tobacco leaves revealed by physiological and proteomics analysis [J/OL]. Ecotoxicol. Environ. Saf., 2020, 202:110856 [2023-04-10]. . |

| [1] | Chengliang XIONG, Qingfu ZHANG, Weiyuan YAO, Tao XIA, Qingping XU, Xixin ZHOU, Yi ZHANG, Lijuan CHEN, Liu YANG. Effects of Different Types of Rice Straw Addition on Soil Microbial Communities Under Continuous Tobacco Cropping [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 233-240. |

| [2] | Xiaoyu SHI, Lianqing JIAO, Min YU, Yixin TIAN, Anni JIAO, Yilin LUAN. Multidimensional Evaluation and Optimization of High Temperature Short Time Process of Astragalus membranaceus [J]. Journal of Agricultural Science and Technology, 2024, 26(7): 223-233. |

| [3] | Fengfeng LIU, Ming WU, Yinghui ZHOU, Yong WU, Jiashu TIAN, Jiayang XU, Zicheng XU, Jiewang HE. Effects of Combined Application of Auxin and Molybdenum on Physiological Metabolism and Quality of Upper Leaves of Flue-cured Tobacco [J]. Journal of Agricultural Science and Technology, 2024, 26(2): 208-215. |

| [4] | Yongjin LIANG, Ruixuan ZHU, Beilei WEI, Xiaomai YUAN, Wuyang CHENG, Bo PENG, Ziting WANG, Jianyu WEI. Effect of Combined Application of Organic Fertilizer on Tobacco Leaf Quality in China: a Meta-analysis [J]. Journal of Agricultural Science and Technology, 2024, 26(12): 164-175. |

| [5] | Yingxuan JIA, Shulin ZHANG, Dajuan ZHANG, Wei DAI, Xiangdong BI. Effects of Phosphorus Recovery on Photosynthetic Pigments and Some Antioxidant Enzymes Activities of Phosphorus Starved Microcystis aeruginosa [J]. Journal of Agricultural Science and Technology, 2024, 26(1): 70-77. |

| [6] | Yongtao HU, Daibin WANG, Yiyin CHEN, Chao YANG, Linlin ZHENG, Hongzhi SHI, Jianan WANG. Research on Contribution of Different Maturation with Fresh Tobacco Quality to Flue-cured Tobacco Quality [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 157-164. |

| [7] | Wen ZHOU, Xiaoheng GUO, Rui XU, Xiaoli WANG, Huiwei NIU, Dan HAN, Huifang SHAO. Effects of Intercropping Pinellia ternata on Growth, Yield and Quality of Flue-cured Tobacco [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 161-169. |

| [8] | Yulu WU, Jiaxin HU, Yuxi CHEN, Bingsong ZHENG, DaoLiang YAN. Effects of External Application of α-Ketoglutarate on Growth, Carbon, Nitrogen and Phosphorus Accumulation and Their Stoichiometric Relationships in Kosteletzkya virginica Under Salt Stress [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 170-177. |

| [9] | Yongyan LIU, Zhengxiong SONG, Jiawei JIN, Jing WANG, Min XU, Junxue ZHOU, Zhanmin LI, Shimin ZHAO, Yunpeng FU, Xiaoyan DAI. Effects of Molybdenum and Zinc Nutrition on Physiological Characteristics and Quality of Flue-cured Tobacco [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 216-224. |

| [10] | Xingfu WU, Fangchan JIAO, Xuejun CHEN, Zhiyu FANG, Guanghai ZHANG, Yihan ZHANG, Yongping LI. Phenotypic Genetic Diversity Analysis of Leaf Shrinkage and Economic Traits of Flue-cured Tobacco for Germplasm Resources [J]. Journal of Agricultural Science and Technology, 2023, 25(10): 54-64. |

| [11] | Geng LI, Yuanyuan ZHAO, Yuyuan CHENG, Jiang WU, Weidong DUAN, Guangting YIN, Qian LI, Chen CHEN, Fei ZHENG, Yuan LIU, Hongzhi SHI. Effects of Different Organic-inorganic Nitrogen Ratios on Soil Carbon and Nitrogen and Upper Leaf Quality in Nanyang Tobacco Area [J]. Journal of Agricultural Science and Technology, 2023, 25(1): 175-186. |

| [12] | Xiaoling ZHAI, Ruixia WANG, Lian ZHANG, Juan JIAO, Yugang LI, Shengjian WANG, Xiaolei QI, Hongmei GE, Shengquan ZHANG. Genetic Relationship of Wheat Derivatives Variety (Line) from Yannong 74(11) Using High-density 90K SNP Array [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 35-43. |

| [13] | Tianwei PENG, Huiya XIE, Sijun LI, Yixuan LIU, Kaifeng SHUAI, Yuanyuan PENG, Qing WANG, Diqin LI. Effects of Sodium Dinitrate with Bacillus Sbutilis Complex on Growth and Physiological Indexes of Tobacco Seedlings [J]. Journal of Agricultural Science and Technology, 2022, 24(4): 154-161. |

| [14] | Yu WANG, Chunguang LI, Huan LIU, Yuehua ZHANG, Xiaomin FENG, Yaoguang LI, Huaiqi LI, Yanqiu JING, Mi SUN. Study on Chloroplast Ultrastructure of Flue-cured Tobacco Leaves and Its Relationship with Degrading Products of Plastid Pigment [J]. Journal of Agricultural Science and Technology, 2022, 24(3): 67-76. |

| [15] | Jun LUO, Hong ZHOU, Facong QIAN, Junying LI. Effects of Shading on Nicotine Synthesis of Flue-cured Tobacco [J]. Journal of Agricultural Science and Technology, 2022, 24(2): 115-123. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号