Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (7): 101-110.DOI: 10.13304/j.nykjdb.2024.0052

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Xiaobo XI( ), Jieyuan DING, Wendi ZHANG, Yangjie SHI, Yifu JIN, Ruihong ZHANG(

), Jieyuan DING, Wendi ZHANG, Yangjie SHI, Yifu JIN, Ruihong ZHANG( )

)

Received:2024-01-19

Accepted:2024-05-09

Online:2025-07-15

Published:2025-07-11

Contact:

Ruihong ZHANG

奚小波( ), 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏(

), 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏( )

)

通讯作者:

张瑞宏

作者简介:奚小波 E-mail: xxbctg@126.com;

基金资助:CLC Number:

Xiaobo XI, Jieyuan DING, Wendi ZHANG, Yangjie SHI, Yifu JIN, Ruihong ZHANG. Design and Experiment of Orchard Obstacle Avoidance Weeding Cultivator[J]. Journal of Agricultural Science and Technology, 2025, 27(7): 101-110.

奚小波, 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏. 一种果园中耕避障除草机的设计与试验[J]. 中国农业科技导报, 2025, 27(7): 101-110.

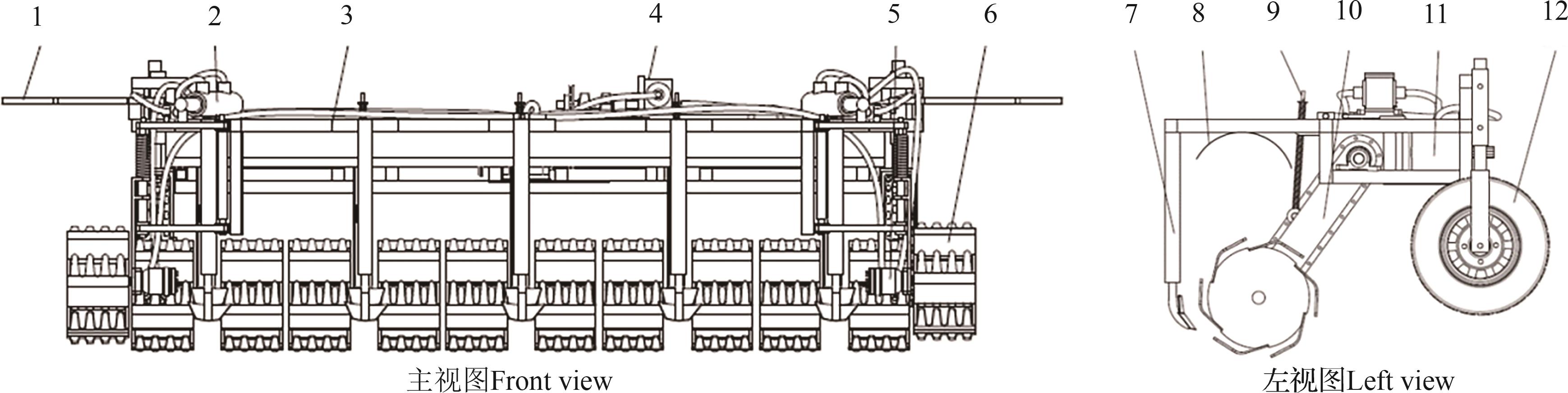

Fig. 1 Overall structure of orchard obstacle avoidance weeding cultivatorNote: 1—Obstacle avoidance pole; 2—Hydraulic obstacle avoidance components; 3—Frame; 4—Hydraulic valve; 5—Hydraulic motor; 6—Weeding wheel; 7—Weeder tine; 8—Mudguard; 9—Spring buffer mechanism; 10—Chain wheel drive box; 11—Intermediate gearbox; 12—Walking wheel.

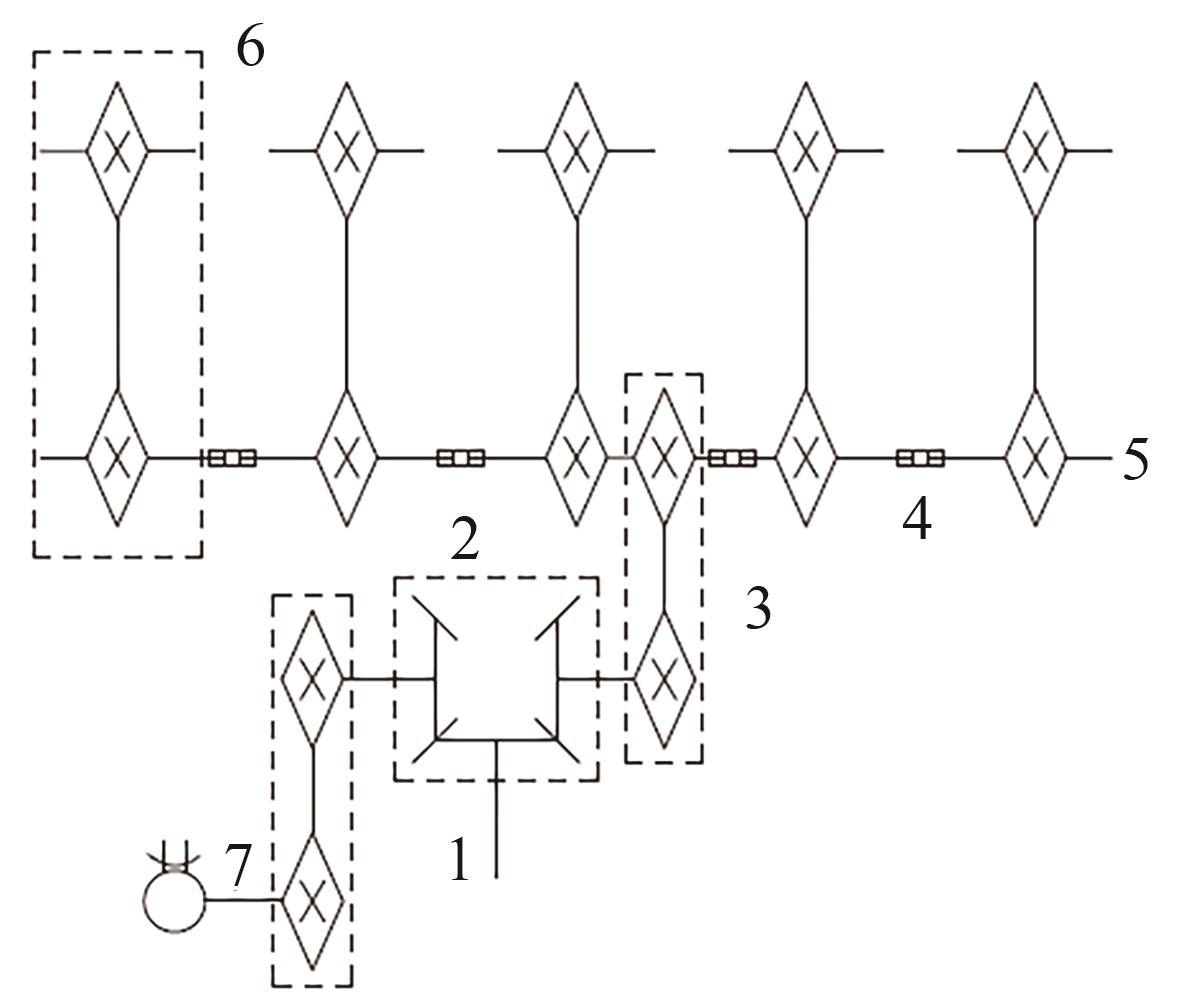

Fig. 2 Inter-row weeding mechanism transmissionNote: 1—Power-failure detection input shaft; 2—Bevel gear box; 3—Sprocket feed; 4—Coupling; 5—Main driving shaft; 6—Weed removal unit; 7—Hydraulic pump.

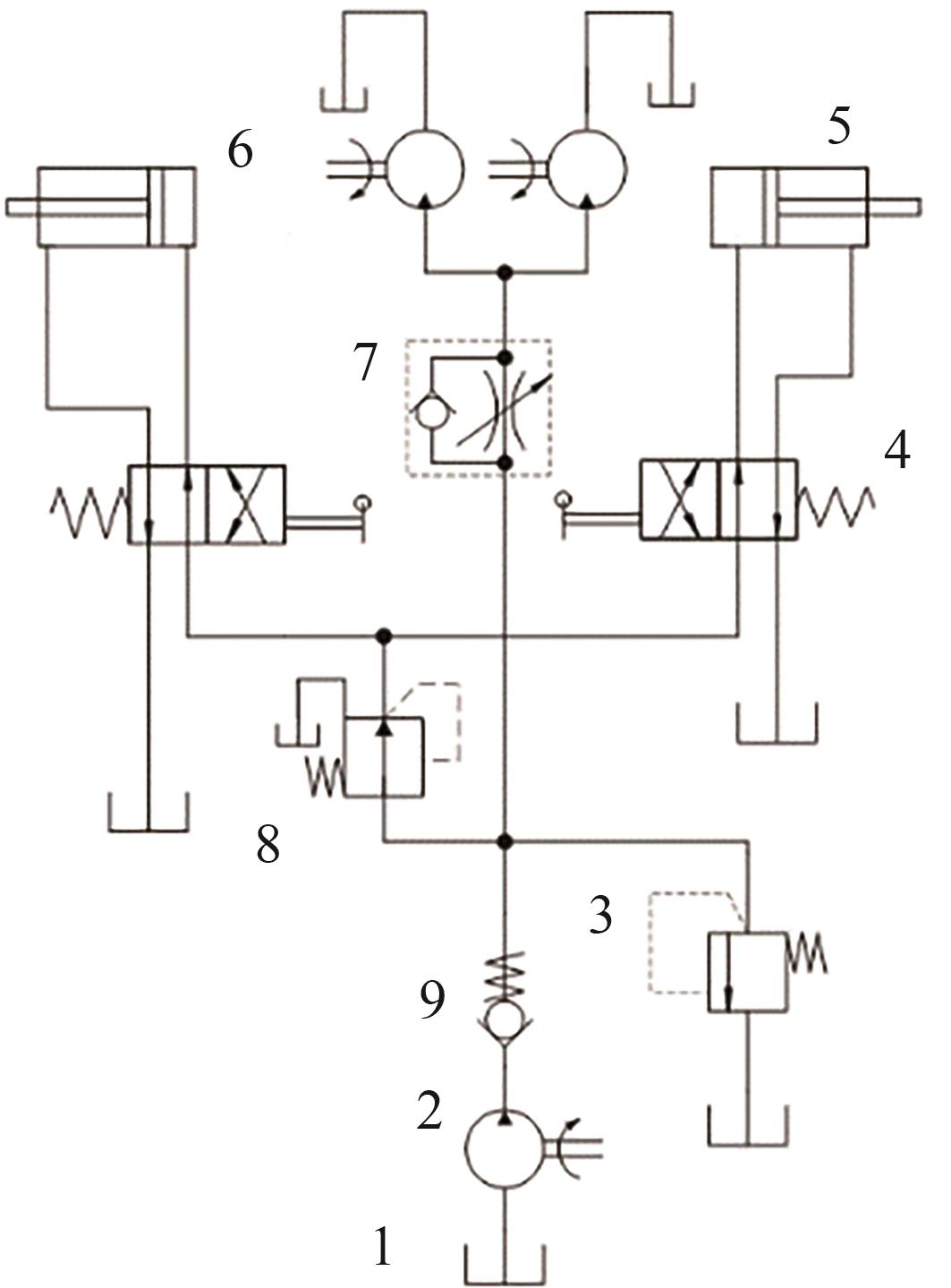

Fig. 3 Intra-row weeding mechanism hydraulic systemNote: 1—Hydraulic reservoir;2—Hydraulic pump;3—Overflow valve;4—Reversing valve;5—Hydraulic cylinder;6—Hydraulic motor;7—Speed-control valve;8—Reducing valve;9—Check valve.

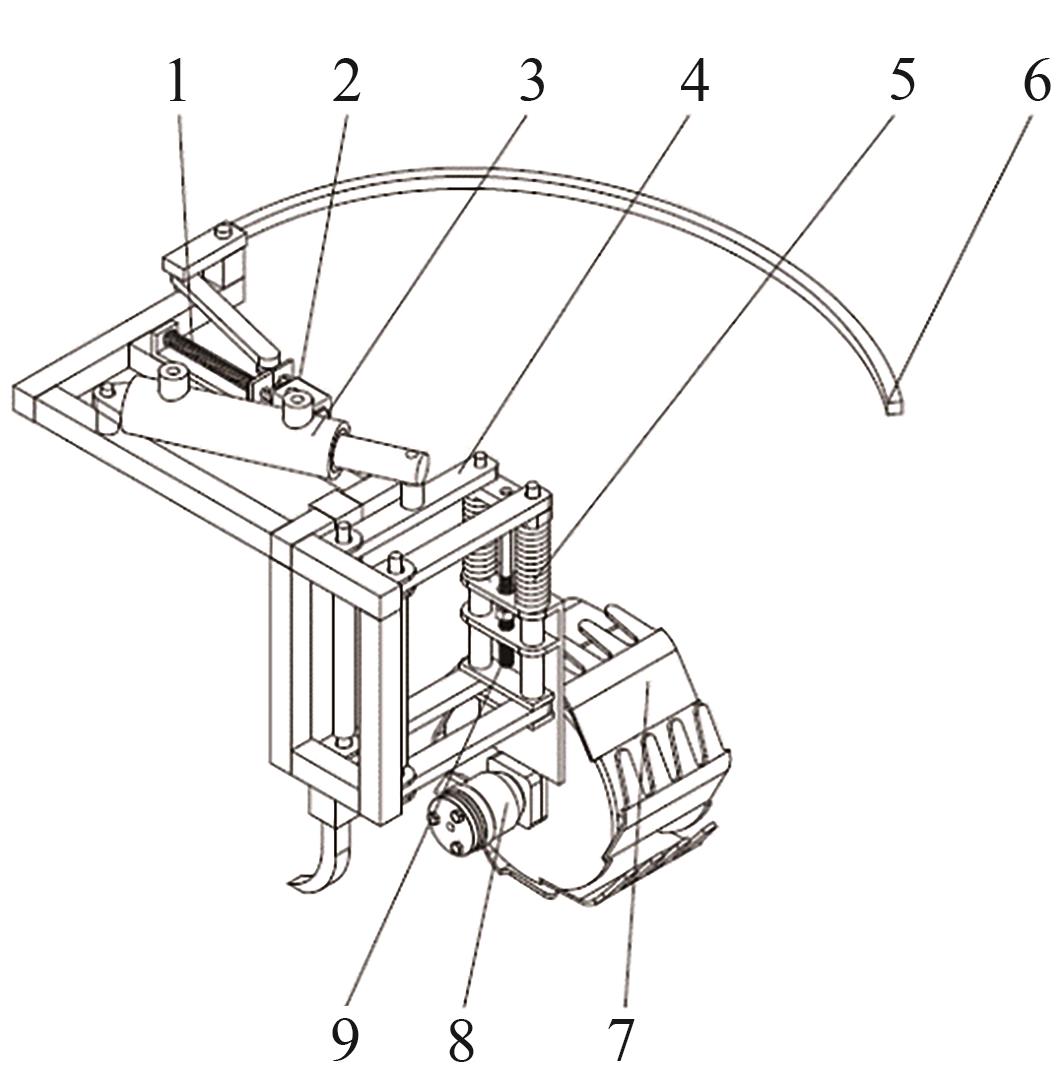

Fig. 5 Obstacle avoidance mechanismNote: 1—Reset spring; 2—Reversing valve; 3—Hydraulic cylinder; 4—Obstacle avoidance connecting rod; 5—Buffer spring; 6—Obstacle avoidance pole; 7—Weeding wheel; 8—Hydraulic motor; 9—Regulating stem.

项目 Item | 数值 Value |

|---|---|

尺寸(长×宽×高) Dimensions (length × width × height)/mm | 2 975×1 438×928 |

与拖拉机连接方式 Coupling mean | 三点悬挂 Trifilar suspension |

配套动力 Matching power/kW | 54.1 |

耕深 Tillage depth/cm | 8 |

作业幅宽 Working width/cm | 300 |

除草轮转速 Weeding wheel rotation speed/(r·min-1) | 500 |

Table 1 Overall performance parameters

项目 Item | 数值 Value |

|---|---|

尺寸(长×宽×高) Dimensions (length × width × height)/mm | 2 975×1 438×928 |

与拖拉机连接方式 Coupling mean | 三点悬挂 Trifilar suspension |

配套动力 Matching power/kW | 54.1 |

耕深 Tillage depth/cm | 8 |

作业幅宽 Working width/cm | 300 |

除草轮转速 Weeding wheel rotation speed/(r·min-1) | 500 |

项目 Item | 参数 Parameter | 数值 Value |

|---|---|---|

土壤颗粒 Soil particle | 泊松比Poisson ratio | 0.3 |

| 剪切模量Shear modulus/Pa | 6×107 | |

| 密度Density /(kg·m-3) | 1 596 | |

| 颗粒半径Particle radius/mm | 10 | |

| 恢复系数Coefficient of restitution | 0.5 | |

| 静摩擦系数Coefficient of static friction | 0.5 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 | |

除草轮 Weeding wheel | 泊松比Poisson ratio | 0.31 |

| 剪切模量Shear modulus/Pa | 2×108 | |

| 密度Density/(kg·m-3) | 7 850 | |

| 恢复系数Coefficient of restitution | 0.35 | |

| 静摩擦系数Coefficient of static friction | 0.29 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 |

Table 2 Discrete element simulation parameters

项目 Item | 参数 Parameter | 数值 Value |

|---|---|---|

土壤颗粒 Soil particle | 泊松比Poisson ratio | 0.3 |

| 剪切模量Shear modulus/Pa | 6×107 | |

| 密度Density /(kg·m-3) | 1 596 | |

| 颗粒半径Particle radius/mm | 10 | |

| 恢复系数Coefficient of restitution | 0.5 | |

| 静摩擦系数Coefficient of static friction | 0.5 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 | |

除草轮 Weeding wheel | 泊松比Poisson ratio | 0.31 |

| 剪切模量Shear modulus/Pa | 2×108 | |

| 密度Density/(kg·m-3) | 7 850 | |

| 恢复系数Coefficient of restitution | 0.35 | |

| 静摩擦系数Coefficient of static friction | 0.29 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 |

| 水平Level | A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) |

|---|---|---|---|

| -1 | 20 | 150 | 1.2 |

| 0 | 50 | 360 | 1.4 |

| 1 | 80 | 500 | 1.6 |

Table 3 Experimental factor level

| 水平Level | A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) |

|---|---|---|---|

| -1 | 20 | 150 | 1.2 |

| 0 | 50 | 360 | 1.4 |

| 1 | 80 | 500 | 1.6 |

序号 Serial number | 因素水平Factor level | 土壤扰动表面积 Soil disturbance surface area/m2 | ||

|---|---|---|---|---|

A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) | ||

| 1 | 20 | 150 | 1.2 | 0.917 2 |

| 2 | 20 | 360 | 1.4 | 1.782 8 |

| 3 | 20 | 500 | 1.6 | 2.095 4 |

| 4 | 50 | 150 | 1.4 | 0.933 2 |

| 5 | 50 | 360 | 1.6 | 1.613 8 |

| 6 | 50 | 500 | 1.2 | 3.033 4 |

| 7 | 80 | 150 | 1.6 | 1.230 4 |

| 8 | 80 | 360 | 1.2 | 2.709 7 |

| 9 | 80 | 500 | 1.4 | 3.144 0 |

| K1 | 4.795 4 | 3.080 8 | 6.660 3 | |

| K2 | 5.580 4 | 6.106 3 | 5.860 0 | |

| K3 | 7.084 1 | 8.272 8 | 4.939 6 | |

| k1 | 1.598 5 | 1.026 9 | 2.220 1 | |

| k2 | 1.860 1 | 2.035 4 | 1.953 3 | |

| k3 | 2.361 4 | 2.757 6 | 1.646 5 | |

| 极差R | 0.762 9 | 1.730 7 | 0.573 6 | |

影响程度 Influence degree | B>A>C | |||

最优组合 Optimal composition | A3B3C1 | |||

Table 4 Orthogonal experimental results and range analysis

序号 Serial number | 因素水平Factor level | 土壤扰动表面积 Soil disturbance surface area/m2 | ||

|---|---|---|---|---|

A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) | ||

| 1 | 20 | 150 | 1.2 | 0.917 2 |

| 2 | 20 | 360 | 1.4 | 1.782 8 |

| 3 | 20 | 500 | 1.6 | 2.095 4 |

| 4 | 50 | 150 | 1.4 | 0.933 2 |

| 5 | 50 | 360 | 1.6 | 1.613 8 |

| 6 | 50 | 500 | 1.2 | 3.033 4 |

| 7 | 80 | 150 | 1.6 | 1.230 4 |

| 8 | 80 | 360 | 1.2 | 2.709 7 |

| 9 | 80 | 500 | 1.4 | 3.144 0 |

| K1 | 4.795 4 | 3.080 8 | 6.660 3 | |

| K2 | 5.580 4 | 6.106 3 | 5.860 0 | |

| K3 | 7.084 1 | 8.272 8 | 4.939 6 | |

| k1 | 1.598 5 | 1.026 9 | 2.220 1 | |

| k2 | 1.860 1 | 2.035 4 | 1.953 3 | |

| k3 | 2.361 4 | 2.757 6 | 1.646 5 | |

| 极差R | 0.762 9 | 1.730 7 | 0.573 6 | |

影响程度 Influence degree | B>A>C | |||

最优组合 Optimal composition | A3B3C1 | |||

| 指标Index | 机具速度 Machine speed/(m·s-1) | ||

|---|---|---|---|

| 1.2 | 1.4 | 1.6 | |

树木总数 Total number of trees | 20 | 25 | 23 |

避障完成总数 Number of obstacle avoidance | 20 | 25 | 23 |

避障率 Obstacle avoidance percentage/% | 100 | 100 | 100 |

Table 5 Obstacle avoidance pass rate test results

| 指标Index | 机具速度 Machine speed/(m·s-1) | ||

|---|---|---|---|

| 1.2 | 1.4 | 1.6 | |

树木总数 Total number of trees | 20 | 25 | 23 |

避障完成总数 Number of obstacle avoidance | 20 | 25 | 23 |

避障率 Obstacle avoidance percentage/% | 100 | 100 | 100 |

测试项目 Testing item | 复位弹簧弹性系数 Elastic coefficient of reset spring/(N·mm-1) | |

|---|---|---|

| 20 | 30 | |

树木总数 Total number of trees | 20 | 20 |

避障完成总数 Number of obstacle avoidance | 20 | 20 |

避障率 Obstacle avoidance percentage/% | 100 | 100 |

果树擦伤数 Number of fruit tree abrasions | 0 | 3 |

果树损伤比 Scratch ratio of fruit trees/% | 0 | 15 |

Table 6 Damage rate test results

测试项目 Testing item | 复位弹簧弹性系数 Elastic coefficient of reset spring/(N·mm-1) | |

|---|---|---|

| 20 | 30 | |

树木总数 Total number of trees | 20 | 20 |

避障完成总数 Number of obstacle avoidance | 20 | 20 |

避障率 Obstacle avoidance percentage/% | 100 | 100 |

果树擦伤数 Number of fruit tree abrasions | 0 | 3 |

果树损伤比 Scratch ratio of fruit trees/% | 0 | 15 |

试验序号 Test number | 果园总面积 Total orchard area/m2 | 去除树干后的土地面积 Land area without tree trunks/m2 | 实际耕作面积 Actual tillage area/m2 | 漏耕率 Missed tillage rate/% |

|---|---|---|---|---|

| 1 | 30 | 24 | 23.25 | 3.23 |

| 2 | 30 | 23 | 22.10 | 4.07 |

| 3 | 30 | 25 | 24.40 | 2.46 |

| 4 | 30 | 26 | 24.95 | 4.21 |

| 5 | 30 | 24 | 23.25 | 3.23 |

Table 7 Missed tillage rate test results

试验序号 Test number | 果园总面积 Total orchard area/m2 | 去除树干后的土地面积 Land area without tree trunks/m2 | 实际耕作面积 Actual tillage area/m2 | 漏耕率 Missed tillage rate/% |

|---|---|---|---|---|

| 1 | 30 | 24 | 23.25 | 3.23 |

| 2 | 30 | 23 | 22.10 | 4.07 |

| 3 | 30 | 25 | 24.40 | 2.46 |

| 4 | 30 | 26 | 24.95 | 4.21 |

| 5 | 30 | 24 | 23.25 | 3.23 |

试验序号 Test number | 平均值 Average/mm | 标准差 Standard deviation/mm | 变异系数 Coefficient of variation/% | 稳定性系数 Stability coefficient/% |

|---|---|---|---|---|

| 1 | 79.5 | 1.68 | 2.11 | 97.89 |

| 2 | 81.2 | 2.28 | 2.81 | 97.19 |

| 3 | 82.0 | 2.00 | 2.49 | 97.51 |

| 4 | 81.0 | 1.14 | 1.40 | 98.60 |

Table 8 Tillage depth test results

试验序号 Test number | 平均值 Average/mm | 标准差 Standard deviation/mm | 变异系数 Coefficient of variation/% | 稳定性系数 Stability coefficient/% |

|---|---|---|---|---|

| 1 | 79.5 | 1.68 | 2.11 | 97.89 |

| 2 | 81.2 | 2.28 | 2.81 | 97.19 |

| 3 | 82.0 | 2.00 | 2.49 | 97.51 |

| 4 | 81.0 | 1.14 | 1.40 | 98.60 |

| [1] | 白勇, 王晓燕, 胡光, 等. 非化学方法在农田杂草防治中的应用[J]. 农业机械学报, 2007, 38(4): 191-196. |

| BAI Y, WANG X Y, HU G, et al.. Review of the development in non-chemical weed management [J]. Trans.Chin.Soc.Agric.Mach., 2007, 38(4): 191-196. | |

| [2] | CORDILL C, GRIFT T E.Design and testing of an intra-row mechanical weeding machine for corn [J]. Biosyst.Eng., 2011,110(3): 247-252. |

| [3] | 齐月, 李俊生, 闫冰, 等. 化学除草剂对农田生态系统野生植物多样性的影响[J]. 生物多样性, 2016, 24(2): 228-236. |

| QI Y, LI J S, YAN B, et al.. Impact of herbicides on wild plant diversity in agro-ecosystems:a review [J]. Biodivers. Sci., 2016, 24(2): 228-236. | |

| [4] | 王金峰, 王金武, 闫东伟, 等. 3SCJ-2型水田行间除草机设计与试验[J]. 农业机械学报, 2017, 48(6): 71-78, 202. |

| WANG J F, WANG J W, YAN D W, et al.. Design and experiment of 3SCJ-2 type row weeding machine for paddy field [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(6): 71-78, 202. | |

| [5] | REBICH R A, COUPE R H, THURMAN E M. Herbicide concentrations in the Mississippi River Basin—the importance of chloroacetanilide herbicide degradates [J]. Sci. Total Environ., 2004, 321(1/2/3): 189-199. |

| [6] | 张晋, 陈伟, 朱继平, 等. 果园自动避障中耕除草管理机设计与试验[J]. 中国农机化学报, 2020, 41(8): 40-49. |

| ZHANG J, CHEN W, ZHU J P, et al.. Design and experiment of automatic obstacle avoidance cultivation weeding management machine [J]. J. Chin. Agric. Mech., 2020, 41(8): 40-49. | |

| [7] | 朱站伟, 汤智辉, 何义川, 等. 果园株间除草自动避障装置的设计与试验[J]. 农机化研究, 2020, 42(6): 147-153. |

| ZHU Z W, TANG Z H, HE Y C, et al.. Design and experiment of automatic obstacle avoidance device for weeding between plants [J]. J. Agric. Mech. Res., 2020, 42(6): 147-153. | |

| [8] | 陈平录, 许静, 翟因敏, 等. 丘陵山区低矮树型果园立式微耕机的设计与试验[J]. 机械设计与制造, 2021(2):299-303. |

| CHEN P L, XU J, ZHAI Y M, et al.. Design and experimental study of vertical micro-cultivator for low trees in hilly orchard [J]. Mach. Des. Manuf., 2021(2): 299-303. | |

| [9] | 鲍秀兰, 严煜, 毛金城, 等. 果园割草机器人甩刀设计与分析[J]. 华中农业大学学报, 2020, 39(6): 136-143. |

| BAO X L, YAN Y, MAO J C, et al.. Design and analyses of swinging blade for orchard mowing robot [J]. J. Huazhong Agric. Univ., 2020, 39(6): 136-143. | |

| [10] | 付作立, 王德成, 李卫, 等. 双圆盘式苜蓿旋转切割器设计与试验[J]. 农业机械学报, 2018, 49(): 214-220. |

| FU Z L, WANG D C, LI W, et al.. Design and experiment of two-disc rotary mower of alfalfa [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(S1): 214-220. | |

| [11] | 王永烁, 康建明, 彭强吉, 等. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| WANG Y S, KANG J M, PENG Q J, et al.. Design and experiment of obstacle avoidance weeding machine for fruit trees [J]. J. Jilin Univ. (Eng. Technol.), 2023, 53(8): 2410-2420. | |

| [12] | SCARFONE A, PICCHIO R, DEL GIUDICE A, et al.. Semi-automatic guidance vs . manual guidance in agriculture: a comparison of work performance in wheat sowing [J/OL]. Electronics, 2021, 10(7): 825 [2024-12-30]. . |

| [13] | 高文杰, 张锋伟, 戴飞, 等. 果园机械化装备研究进展与展望[J]. 林业机械与木工设备, 2021, 49(12): 9-20. |

| GAO W J, ZHANG F W, DAI F, et al.. Research progress and prospects of orchard mechanized equipment [J]. For. Mach. Woodwork. Equip., 2021, 49(12): 9-20. | |

| [14] | 吕金庆, 刘金妮, 赵治明, 等. 马铃薯碎土整地联合作业机设计与试验[J]. 农业机械学报, 2023, 54(8): 19-29. |

| LYU J Q, LIU J N, ZHAO Z M, et al.. Design and test of key components of potato soil-crushing site preparation machine [J]. Trans. Chin. Soc. Agric. Mach., 2023, 54(8): 19-29. | |

| [15] | 杨启志, 杨鑫宇, 赫明胜, 等. 葡萄分层旋抛式清土起藤机高效旋抛刀设计与试验[J]. 农业工程学报, 2022, 38(24): 44-51. |

| YANG Q Z, YANG X Y, HE M S, et al.. Design and experiment of the rotary throwing knife of wine grape cleaning machine [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(24): 44-51. | |

| [16] | 张帅磊. 深松铲错位布置对土壤扰动影响的仿真与试验研究[D]. 杨凌: 西北农林科技大学, 2018. |

| ZHANG S L. Simulations and experiments of soil disturbance as affected by the dislocation arrangement of subsoilers [D]. Yangling: Northwest A&F University, 2018. | |

| [17] | 崔宏伟. 水田除草机自动避苗控制系统研究[D]. 广州: 华南农业大学, 2017. |

| CUI H W. Study on control system with automatic avoiding rice seedlings ofweeder for paddy [D]. Guangzhou: South China Agricultural University, 2017. | |

| [18] | 丁艳, 朱继平, 袁栋, 等. 旋耕机: [S]. 北京:中国标准出版社, 2017. |

| [19] | 李宝筏. 农业机械学[M]. 北京: 中国农业出版社, 2003:1-438. |

| [20] | 朱站伟. 果园株间除草自动避障装置的设计与试验研究[D]. 石河子: 石河子大学, 2020. |

| ZHU Z W.Design and experimental study of an automatic obstacle avoidance device between weeds in orchards [D]. Shihezi: Shihezi University, 2020. | |

| [21] | 中国农机研究院. 农业机械设计手册[M]. 北京: 中国农业科学技术出版社, 2007: 1-1885. |

| [22] | 沈启扬, 雷哓晖, 马拯胞, 等. F. US-UFO型果园避障割草机试验研究[J]. 中国农机化学报, 2021, 42(10): 65-71, 77. |

| SHEN Q Y, LEI X H, MA Z B, et al.. Experimental study on F. US-UFO mower for avoiding obstacles in orchards [J]. J. Chin. Agric. Mech., 2021, 42(10): 65-71, 77. | |

| [23] | 杨毅, 弋晓康, 何义川, 等. 主干型果园株间避障割草机的设计与试验[J]. 塔里木大学学报, 2023, 35(4): 78-87. |

| YANG Y, YI X K, HE Y C, et al.. Design and experiment of obstacle avoidance mower for trunk orchards [J]. J. Tarim Univ., 2023, 35(4): 78-87. | |

| [24] | 李雪军, 王鹏飞, 丁顺荣, 等. 基于虚拟正交试验果园垄面割草机侧刀盘切割性能分析[J]. 中国农业科技导报, 2020, 22(9): 113-121. |

| LI X J, WANG P F, DING S R, et al.. Cutting performance of side cutter head of orchard mower based on virtual orthogonal test [J]. J. Agric. Sci. Technol., 2020, 22(9): 113-121. |

| [1] | Jing XU, Han LI, Pinglu CHEN, Jiangni LUO, Chenglu TANG, Muhua LIU. Calibration and Validation of Discrete Element Model for Camelliaoleifera Seed Meal [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 112-121. |

| [2] | Changlong FENG, Chunguang HUANG, Chenyang NING, Shuping LI, Kejin CHEN. Optimization of Performance and Characteristics of Spiral Drill Bit Excavation Mechanism for Planting Machine [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 89-98. |

| [3] | Xiangzhou TIAN, Fuqiang HE, Fajiang CHEN, Luxin ZHAN. Calibration of Discrete Elemental Parameters of Wood Powder with Different Moisture Content Based on Angle of Repose [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 118-128. |

| [4] | Guoqiang DUN, Lei WANG, Xinxin JI, Xinbo JIANG, Yu ZHAO, Na GUO. Calibration and Verification of Discrete Element Parameters of Jinxiang Purple Garlic Seeds [J]. Journal of Agricultural Science and Technology, 2024, 26(8): 131-139. |

| [5] | Shijian BAI, Jinge HU, Chao LI, Junshe CAI. Effects of 3 Trellis Systems on Cultivation Characters and Berry Quality of ‘Xinyu’ Grape [J]. Journal of Agricultural Science and Technology, 2024, 26(8): 63-73. |

| [6] | Guoqiang DUN, Xingpeng WU, Xinxin JI, Fuli ZHANG, Wenyi JI, Yongzhen YANG. Simulation and Optimization of Soybean Plot Metering Device with Double Swing Plate [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 82-90. |

| [7] | Ming LI, Shuai DONG, Yongqiang PANG, Jiehua YAN, Wangzhong YE. Design Improvement and Test of Aeolian Sand Mixing Cutter [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 87-96. |

| [8] | Yuanhao HUANG, Lazhen QUAN, Guangfa HU, Wei QUAN, Fanggang SHI. Calibration of Discrete Element Contact Parameters for Various Materials and Soils with Different Moisture Content [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 98-109. |

| [9] | Lin CHEN, Nanhui YU, Lizong WANG, Jijun FAN, Gang LEI, Xiaopeng LIU, Long ZHOU, Jin ZHOU. Measurement of Contact Parameters and Discrete Element Simulation Calibration of Rice Bran and Broken Rice [J]. Journal of Agricultural Science and Technology, 2024, 26(2): 127-136. |

| [10] | Hao GUO, Ronglei TAN, Jinpeng YANG, Jun YU, Wenchang HUANG, Jiuhong YANG, Baoming QIAO, Ruiwei YANG, Fangsen XU, Chunlei YANG, Guangda DING. Effects of Shading Cultivation on Leaf Uniformity of Cigar-wrapper Tobacco (Nicotiana tabacum) [J]. Journal of Agricultural Science and Technology, 2024, 26(2): 216-225. |

| [11] | Dafang YANG, Feixiang LI, Yuefeng GE, Yichen LI. Study on Fertilizer Discharge Performance of External Groove Wheel Fertilizer Applicator Based on Discrete Element Method [J]. Journal of Agricultural Science and Technology, 2024, 26(12): 88-97. |

| [12] | Ruikang SUN, Jinghua FU, Minjun XU. Research Progress of Aquaponics System [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 227-233. |

| [13] | Xiaoyun HUANG, Xiusheng HUANG, Yuanquan CHEN, Xiaohong LIN, Haidong HAN, Deqing FENG, Tao LUO. Environmental Impact Analysis of Anoectochilus roxburghii Imitated Wild Cultivated Under Fir Trees [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 176-185. |

| [14] | Shiying ZHOU, Yanchen LIU, Yang ZHANG, Xuesong YANG, Weijun GUAN, Yang GAO. Isolational Culture and Biological Identification of Japanese Large Ear White Rabbit Bone Marrow Mesenchymal Stem Cells [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 96-105. |

| [15] | Zhongxiu RAO, Jimin SUN, Na ZHANG, Longtao LI, Chunhua DONG, Zengping YANG, Fengqiu HUANG. Impacts from Adding Artemisia argyi Straw into Substrates on Growth and Quality of Pleurotus ostreatus [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 208-215. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号