中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (6): 154-164.DOI: 10.13304/j.nykjdb.2021.1035

• 食品质量 加工储运 • 上一篇

杨伊琳1( ), 丁俊雄1, 吴小华1(

), 丁俊雄1, 吴小华1( ), 王鹏1, 孙东亮1, 于馨尧1, 张振涛2, 李栋3

), 王鹏1, 孙东亮1, 于馨尧1, 张振涛2, 李栋3

收稿日期:2021-12-03

接受日期:2022-05-05

出版日期:2023-06-01

发布日期:2023-07-28

通讯作者:

吴小华

作者简介:杨伊琳E-mail:yangyilin210@163.com;

基金资助:

Yilin YANG1( ), Junxiong DING1, Xiaohua WU1(

), Junxiong DING1, Xiaohua WU1( ), Peng WANG1, Dongliang SUN1, Xinyao YU1, Zhentao ZHANG2, Dong LI3

), Peng WANG1, Dongliang SUN1, Xinyao YU1, Zhentao ZHANG2, Dong LI3

Received:2021-12-03

Accepted:2022-05-05

Online:2023-06-01

Published:2023-07-28

Contact:

Xiaohua WU

摘要:

为确定香菇热风干燥的最佳工艺参数,以新鲜香菇为试验对象,开展多目标优化研究。以相对湿度、风速和单位载荷量为自变量,以干香菇的色差、水溶性蛋白含量和干燥时间为响应值,建立香菇热风干燥多目标综合评分模型,通过响应曲面法优化得到香菇热风干燥的最佳工艺参数。结果表明,色差为3.58、水溶性蛋白含量为46.39 mg·g-1、干燥时间为12.5 h,干燥条件50 ℃时,最佳干燥工艺参数为相对湿度27.1%、风速5 m·s-1、单位载荷量4 kg·m-2;将优化目标的模型预测值与试验值相比较,平均相对误差仅为6.6%,最大相对误差为7.4%。研究结果表明,基于响应曲面法建立的综合评分预测模型不仅可用于香菇热风干燥过程,还为提高干香菇的营养和感官品质提供理论指导。

中图分类号:

杨伊琳, 丁俊雄, 吴小华, 王鹏, 孙东亮, 于馨尧, 张振涛, 李栋. 基于响应曲面法优化香菇热风干燥工艺参数[J]. 中国农业科技导报, 2023, 25(6): 154-164.

Yilin YANG, Junxiong DING, Xiaohua WU, Peng WANG, Dongliang SUN, Xinyao YU, Zhentao ZHANG, Dong LI. Optimization of Hot-air Drying Process Parameters of Lentinus edodes Based on Response Surface[J]. Journal of Agricultural Science and Technology, 2023, 25(6): 154-164.

| 参数 Parameter | 水平 Level | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| 干燥温度 Drying temperature/℃ | 45 | 50 | 55 | 60 |

| 相对湿度 Relative humidity/% | 25 | 30 | 35 | 40 |

| 风速 Wind speed/(m·s-1) | 2 | 3 | 4 | 5 |

| 单位载荷量 Unit load/(kg·m-2) | 2 | 4 | 6 | 8 |

表1 香菇水分比热风干燥试验方案

Table 1 Test plan for the moisture ratio of lentinus edodes to hot air drying

| 参数 Parameter | 水平 Level | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| 干燥温度 Drying temperature/℃ | 45 | 50 | 55 | 60 |

| 相对湿度 Relative humidity/% | 25 | 30 | 35 | 40 |

| 风速 Wind speed/(m·s-1) | 2 | 3 | 4 | 5 |

| 单位载荷量 Unit load/(kg·m-2) | 2 | 4 | 6 | 8 |

| 水平 Level | 因素 Factor | ||

|---|---|---|---|

| X1:相对湿度 Relative humidity/% | X2:风速 Wind speed/(m·s-1) | X3:单位载荷量 Unit load/ (kg·m-2) | |

| -1 | 25 | 3 | 4 |

| 0 | 30 | 4 | 6 |

| 1 | 35 | 5 | 8 |

表2 响应曲面工艺参数与水平

Table 2 Response surface technology parameter and level

| 水平 Level | 因素 Factor | ||

|---|---|---|---|

| X1:相对湿度 Relative humidity/% | X2:风速 Wind speed/(m·s-1) | X3:单位载荷量 Unit load/ (kg·m-2) | |

| -1 | 25 | 3 | 4 |

| 0 | 30 | 4 | 6 |

| 1 | 35 | 5 | 8 |

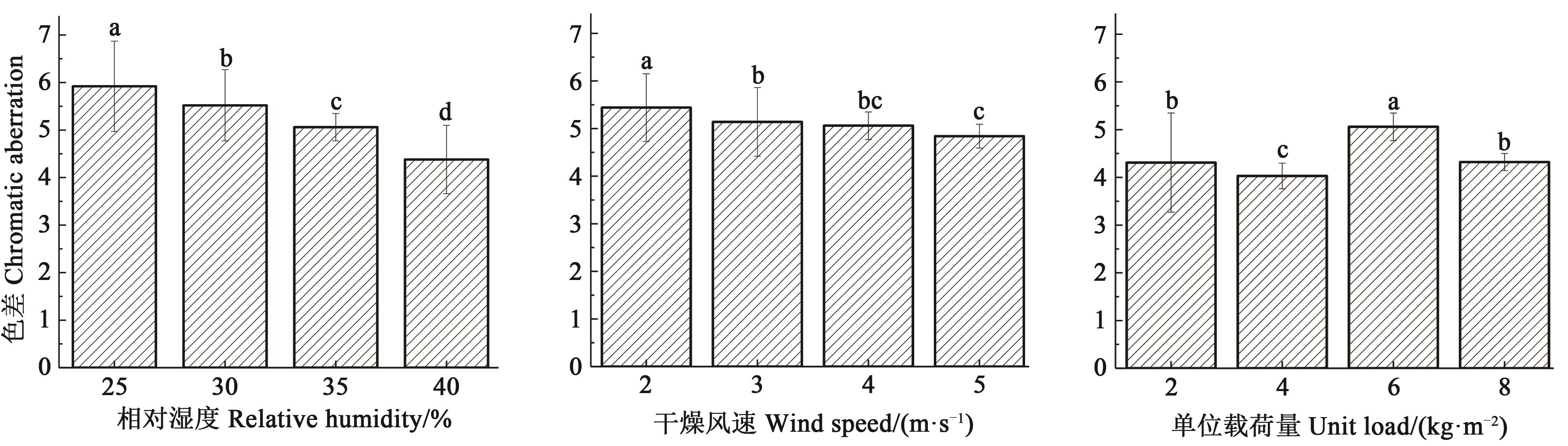

图1 不同干燥参数下干香菇的色差注:图中不同小写字母表示P<0.05水平差异显著。

Fig. 1 Color difference of dry Lentinus edodes under drying parametersNote:Different small letters in the figure indicate significant differences at P<0.05 level.

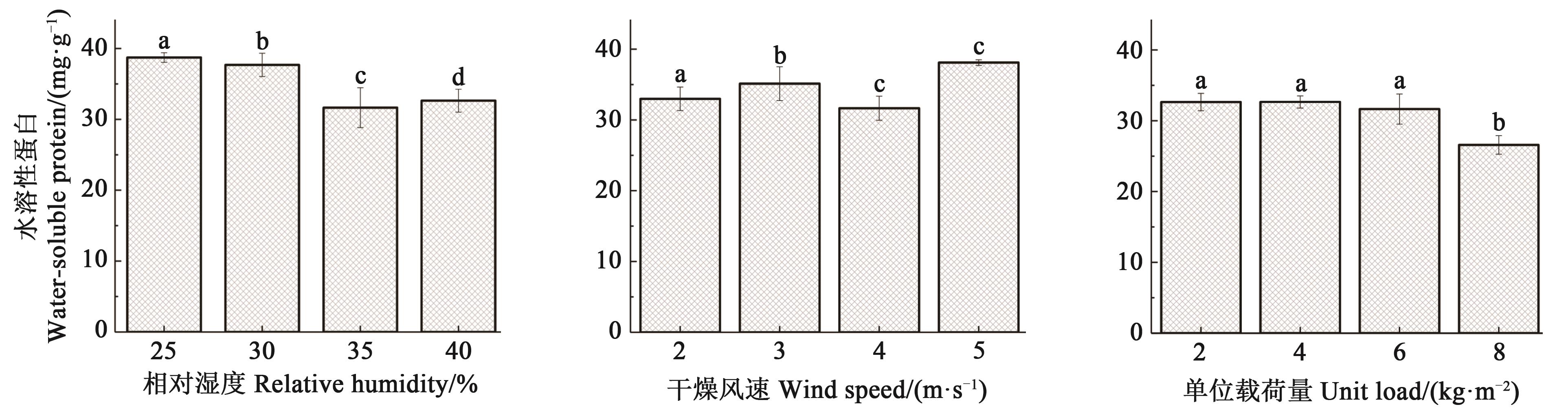

图2 不同干燥参数下香菇的水溶性蛋白含量注:图中不同小写字母表示P<0.05水平差异显著。

Fig. 2 Water-soluble protein content of Lentinus edodes under different drying parametersNote:Different small letters in the figure indicate significant differences at P<0.05 level.

| 序号 Number | X1 | X2 | X3 | Y1 | Y2/(mg·g-1) | Y3/h |

|---|---|---|---|---|---|---|

| 1 | 0 | -1 | -1 | 3.56 | 45.15 | 15.00 |

| 2 | -1 | 1 | 0 | 4.40 | 40.32 | 13.50 |

| 3 | 0 | 0 | 0 | 4.22 | 35.24 | 14.50 |

| 4 | -1 | -1 | 0 | 5.48 | 40.66 | 14.50 |

| 5 | 1 | 0 | -1 | 3.87 | 42.40 | 13.50 |

| 6 | 0 | 0 | 0 | 3.92 | 38.72 | 13.50 |

| 7 | 1 | 1 | 0 | 3.38 | 37.85 | 15.00 |

| 8 | 0 | 1 | -1 | 3.17 | 44.82 | 13.00 |

| 9 | 1 | -1 | 0 | 3.95 | 51.05 | 16.50 |

| 10 | -1 | 0 | 1 | 4.84 | 40.74 | 15.00 |

| 11 | 0 | 0 | 0 | 4.52 | 37.49 | 14.00 |

| 12 | 0 | 0 | 0 | 4.26 | 36.24 | 14.00 |

| 13 | 0 | -1 | 1 | 5.02 | 51.77 | 16.00 |

| 14 | 1 | 0 | 1 | 3.67 | 42.34 | 17.00 |

| 15 | 0 | 1 | 1 | 4.04 | 47.68 | 14.00 |

| 16 | -1 | 0 | -1 | 4.36 | 42.14 | 12.50 |

| 17 | 0 | 0 | 0 | 4.17 | 38.11 | 14.00 |

表3 响应曲面试验条件及结果

Table 3 Response surface experimental conditions and results

| 序号 Number | X1 | X2 | X3 | Y1 | Y2/(mg·g-1) | Y3/h |

|---|---|---|---|---|---|---|

| 1 | 0 | -1 | -1 | 3.56 | 45.15 | 15.00 |

| 2 | -1 | 1 | 0 | 4.40 | 40.32 | 13.50 |

| 3 | 0 | 0 | 0 | 4.22 | 35.24 | 14.50 |

| 4 | -1 | -1 | 0 | 5.48 | 40.66 | 14.50 |

| 5 | 1 | 0 | -1 | 3.87 | 42.40 | 13.50 |

| 6 | 0 | 0 | 0 | 3.92 | 38.72 | 13.50 |

| 7 | 1 | 1 | 0 | 3.38 | 37.85 | 15.00 |

| 8 | 0 | 1 | -1 | 3.17 | 44.82 | 13.00 |

| 9 | 1 | -1 | 0 | 3.95 | 51.05 | 16.50 |

| 10 | -1 | 0 | 1 | 4.84 | 40.74 | 15.00 |

| 11 | 0 | 0 | 0 | 4.52 | 37.49 | 14.00 |

| 12 | 0 | 0 | 0 | 4.26 | 36.24 | 14.00 |

| 13 | 0 | -1 | 1 | 5.02 | 51.77 | 16.00 |

| 14 | 1 | 0 | 1 | 3.67 | 42.34 | 17.00 |

| 15 | 0 | 1 | 1 | 4.04 | 47.68 | 14.00 |

| 16 | -1 | 0 | -1 | 4.36 | 42.14 | 12.50 |

| 17 | 0 | 0 | 0 | 4.17 | 38.11 | 14.00 |

方差来源 Source of variance | Y1 | Y2 | Y3 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

总和 Sum | 自由度 Degree of freedom | 平均值 Average value | F值 F value | P值 P value | 总和 Sum | 自由度 Degree of freedom | 平均值 Average value/(mg·g-1) | F值 F value | P值 P value | 总和 Sum | 自由度 Degree of freedom | 平均值 Average value/h | F值 F value | P值 P value | |

| 模型 Model | 4.76 | 9 | 0.53 | 4.52 | 0.029 7 | 338.30 | 9 | 37.59 | 6.94 | 0.009 1 | 20.63 | 9 | 2.29 | 5.70 | 0.015 9 |

| X1 | 2.22 | 1 | 2.22 | 18.95 | 0.003 3 | 11.96 | 1 | 11.96 | 2.21 | 0.181 0 | 5.28 | 1 | 5.28 | 13.14 | 0.008 4 |

| X2 | 1.14 | 1 | 1.14 | 9.75 | 0.016 8 | 40.32 | 1 | 40.32 | 7.44 | 0.029 4 | 5.28 | 1 | 5.28 | 13.14 | 0.008 4 |

| X3 | 0.85 | 1 | 0.85 | 7.28 | 0.030 7 | 8.04 | 1 | 8.04 | 1.48 | 0.262 6 | 8.00 | 1 | 8.00 | 19.91 | 0.002 9 |

| X1X2 | 0.07 | 1 | 0.07 | 0.56 | 0.480 0 | 41.34 | 1 | 41.34 | 7.63 | 0.028 0 | 0.06 | 1 | 0.06 | 0.16 | 0.705 0 |

| X1X3 | 0.12 | 1 | 0.12 | 0.99 | 0.353 1 | 0.45 | 1 | 0.45 | 0.08 | 0.781 8 | 0.25 | 1 | 0.25 | 0.62 | 0.456 1 |

| X2X3 | 0.09 | 1 | 0.09 | 0.74 | 0.416 8 | 3.53 | 1 | 3.53 | 0.65 | 0.445 8 | 0.00 | 1 | 0.00 | 0.00 | 1.000 0 |

| X12 | 0.11 | 1 | 0.11 | 0.93 | 0.366 1 | 0.02 | 1 | 0.02 | 0.38×10-2 | 0.952 5 | 0.81 | 1 | 0.81 | 2.01 | 0.199 6 |

| X22 | 0.02 | 1 | 0.02 | 0.21 | 0.660 0 | 121.87 | 1 | 121.87 | 22.49 | 0.002 1 | 0.81 | 1 | 0.81 | 2.01 | 0.199 6 |

| X32 | 0.16 | 1 | 0.16 | 1.36 | 0.282 4 | 97.62 | 1 | 97.62 | 18.02 | 0.003 8 | 0.02 | 1 | 0.02 | 0.04 | 0.845 4 |

| 残差 Residual | 0.82 | 7 | 0.17 | — | — | 37.93 | 7 | 5.42 | — | — | 2.81 | 7 | 0.40 | — | — |

| 失拟性 Lack of fit | 0.63 | 3 | 0.21 | 4.59 | 0.087 5 | 29.95 | 3 | 9.98 | 5.01 | 0.076 9 | 2.31 | 3 | 0.77 | 6.17 | 0.055 6 |

| 纯误差 Pure error | 0.18 | 4 | 0.05 | — | — | 7.98 | 4 | 1.99 | — | — | 0.50 | 4 | 0.13 | — | — |

| 总离差 Total deviation | 5.57 | 16 | — | — | — | 376.23 | 16 | — | — | — | 23.44 | 16 | — | — | — |

表4 香菇色差回归方程系数及方差分析

Table 4 Mushroom color difference regression equation coefficient and variance analysis table

方差来源 Source of variance | Y1 | Y2 | Y3 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

总和 Sum | 自由度 Degree of freedom | 平均值 Average value | F值 F value | P值 P value | 总和 Sum | 自由度 Degree of freedom | 平均值 Average value/(mg·g-1) | F值 F value | P值 P value | 总和 Sum | 自由度 Degree of freedom | 平均值 Average value/h | F值 F value | P值 P value | |

| 模型 Model | 4.76 | 9 | 0.53 | 4.52 | 0.029 7 | 338.30 | 9 | 37.59 | 6.94 | 0.009 1 | 20.63 | 9 | 2.29 | 5.70 | 0.015 9 |

| X1 | 2.22 | 1 | 2.22 | 18.95 | 0.003 3 | 11.96 | 1 | 11.96 | 2.21 | 0.181 0 | 5.28 | 1 | 5.28 | 13.14 | 0.008 4 |

| X2 | 1.14 | 1 | 1.14 | 9.75 | 0.016 8 | 40.32 | 1 | 40.32 | 7.44 | 0.029 4 | 5.28 | 1 | 5.28 | 13.14 | 0.008 4 |

| X3 | 0.85 | 1 | 0.85 | 7.28 | 0.030 7 | 8.04 | 1 | 8.04 | 1.48 | 0.262 6 | 8.00 | 1 | 8.00 | 19.91 | 0.002 9 |

| X1X2 | 0.07 | 1 | 0.07 | 0.56 | 0.480 0 | 41.34 | 1 | 41.34 | 7.63 | 0.028 0 | 0.06 | 1 | 0.06 | 0.16 | 0.705 0 |

| X1X3 | 0.12 | 1 | 0.12 | 0.99 | 0.353 1 | 0.45 | 1 | 0.45 | 0.08 | 0.781 8 | 0.25 | 1 | 0.25 | 0.62 | 0.456 1 |

| X2X3 | 0.09 | 1 | 0.09 | 0.74 | 0.416 8 | 3.53 | 1 | 3.53 | 0.65 | 0.445 8 | 0.00 | 1 | 0.00 | 0.00 | 1.000 0 |

| X12 | 0.11 | 1 | 0.11 | 0.93 | 0.366 1 | 0.02 | 1 | 0.02 | 0.38×10-2 | 0.952 5 | 0.81 | 1 | 0.81 | 2.01 | 0.199 6 |

| X22 | 0.02 | 1 | 0.02 | 0.21 | 0.660 0 | 121.87 | 1 | 121.87 | 22.49 | 0.002 1 | 0.81 | 1 | 0.81 | 2.01 | 0.199 6 |

| X32 | 0.16 | 1 | 0.16 | 1.36 | 0.282 4 | 97.62 | 1 | 97.62 | 18.02 | 0.003 8 | 0.02 | 1 | 0.02 | 0.04 | 0.845 4 |

| 残差 Residual | 0.82 | 7 | 0.17 | — | — | 37.93 | 7 | 5.42 | — | — | 2.81 | 7 | 0.40 | — | — |

| 失拟性 Lack of fit | 0.63 | 3 | 0.21 | 4.59 | 0.087 5 | 29.95 | 3 | 9.98 | 5.01 | 0.076 9 | 2.31 | 3 | 0.77 | 6.17 | 0.055 6 |

| 纯误差 Pure error | 0.18 | 4 | 0.05 | — | — | 7.98 | 4 | 1.99 | — | — | 0.50 | 4 | 0.13 | — | — |

| 总离差 Total deviation | 5.57 | 16 | — | — | — | 376.23 | 16 | — | — | — | 23.44 | 16 | — | — | — |

| 参数 Parameter | 优化结果 Optimization results | 相对湿度 Relative humidity/% | 风速 Wind speed/(m·s-1) | 单位载荷量 Unit load/(kg·m-2) |

|---|---|---|---|---|

| 色差 Chromatic aberration | 3.301 | 33.58 | 5.0 | 4.0 |

| 水溶性蛋白含量 Water-soluble protein content/(mg·g-1) | 55.02 | 33.80 | 3.0 | 8.0 |

| 干燥时间 Drying time/h | 12.57 | 27.69 | 4.8 | 4.0 |

表5 单目标优化结果

Table 5 Model regression validation data

| 参数 Parameter | 优化结果 Optimization results | 相对湿度 Relative humidity/% | 风速 Wind speed/(m·s-1) | 单位载荷量 Unit load/(kg·m-2) |

|---|---|---|---|---|

| 色差 Chromatic aberration | 3.301 | 33.58 | 5.0 | 4.0 |

| 水溶性蛋白含量 Water-soluble protein content/(mg·g-1) | 55.02 | 33.80 | 3.0 | 8.0 |

| 干燥时间 Drying time/h | 12.57 | 27.69 | 4.8 | 4.0 |

方差来源 Source of variance | 总和 Sum | 自由度 Degree of freedom | 平均值 Average value | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 0.308 6 | 9 | 0.034 3 | 4.11 | 0.038 0 |

| X1 | 0.014 1 | 1 | 0.014 1 | 1.69 | 0.234 4 |

| X2 | 0.002 5 | 1 | 0.002 5 | 0.30 | 0.600 7 |

| X3 | 0.030 0 | 1 | 0.030 0 | 3.59 | 0.100 1 |

| X1X2 | 0.042 4 | 1 | 0.042 4 | 5.08 | 0.058 8 |

| X1X3 | 0.000 6 | 1 | 0.000 6 | 0.07 | 0.793 0 |

| X2X3 | 0.000 8 | 1 | 0.000 8 | 0.09 | 0.771 4 |

| X12 | 0.007 5 | 1 | 0.007 5 | 0.90 | 0.374 8 |

| X22 | 0.091 0 | 1 | 0.091 0 | 10.90 | 0.013 1 |

| X32 | 0.113 3 | 1 | 0.113 3 | 13.56 | 0.007 8 |

| 残差 Residual | 0.058 5 | 7 | 0.008 4 | — | — |

| 失拟性 Lack of fit | 0.038 0 | 3 | 0.012 7 | 2.49 | 0.199 9 |

| 纯误差 Pure error | 0.020 4 | 4 | 0.005 1 | — | — |

| 总离差 Total deviation | 0.367 0 | 16 | — | — | — |

表6 香菇综合评分回归方程系数及方差

Table 6 Mushroom drying time regression equation coefficient and variance analysis table

方差来源 Source of variance | 总和 Sum | 自由度 Degree of freedom | 平均值 Average value | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 0.308 6 | 9 | 0.034 3 | 4.11 | 0.038 0 |

| X1 | 0.014 1 | 1 | 0.014 1 | 1.69 | 0.234 4 |

| X2 | 0.002 5 | 1 | 0.002 5 | 0.30 | 0.600 7 |

| X3 | 0.030 0 | 1 | 0.030 0 | 3.59 | 0.100 1 |

| X1X2 | 0.042 4 | 1 | 0.042 4 | 5.08 | 0.058 8 |

| X1X3 | 0.000 6 | 1 | 0.000 6 | 0.07 | 0.793 0 |

| X2X3 | 0.000 8 | 1 | 0.000 8 | 0.09 | 0.771 4 |

| X12 | 0.007 5 | 1 | 0.007 5 | 0.90 | 0.374 8 |

| X22 | 0.091 0 | 1 | 0.091 0 | 10.90 | 0.013 1 |

| X32 | 0.113 3 | 1 | 0.113 3 | 13.56 | 0.007 8 |

| 残差 Residual | 0.058 5 | 7 | 0.008 4 | — | — |

| 失拟性 Lack of fit | 0.038 0 | 3 | 0.012 7 | 2.49 | 0.199 9 |

| 纯误差 Pure error | 0.020 4 | 4 | 0.005 1 | — | — |

| 总离差 Total deviation | 0.367 0 | 16 | — | — | — |

响应值 Response value | 色差 Chromatic aberration | 水溶性蛋白含量 Water-soluble protein content/(mg·g-1) | 干燥时间 Drying time/h |

|---|---|---|---|

| 预测值 Predictive value | 3.58 | 46.39 | 12.5 |

| 试验值 Experimental value | 3.79 | 49.82 | 13.5 |

| 相对误差 Relative error/% | 5.5 | 6.9 | 7.4 |

表7 试验值与预测值对比

Table 7 Comparison of experimental value and predicted value

响应值 Response value | 色差 Chromatic aberration | 水溶性蛋白含量 Water-soluble protein content/(mg·g-1) | 干燥时间 Drying time/h |

|---|---|---|---|

| 预测值 Predictive value | 3.58 | 46.39 | 12.5 |

| 试验值 Experimental value | 3.79 | 49.82 | 13.5 |

| 相对误差 Relative error/% | 5.5 | 6.9 | 7.4 |

| 1 | 王教领,宋卫东,任彩红,等.我国香菇干燥技术研究进展[J].中国农机化学报,2021,42(7):76-83. |

| WANG J L, SONG W D, REN C H, et al.. Research on the drying progress of lentinus edodes in China [J]. J. Chin. Agric. Mech., 2021, 42(7): 76-83. | |

| 2 | SANODIYA G S, THAKUR G B, PRASAD K S. Lentinus edodes (a macrofungus with pharmacological activities) [J]. Curr. Med. Chem., 2010,17(22): 2419-2430. |

| 3 | CHEN H L, JU Y, LI J J, et al.. Antioxidant activities of polysaccharides from Lentinus edodes and their significance for disease prevention [J]. Int. J. Biol. Macromol., 2012, 50(1): 214-218. |

| 4 | FEENEY M J, DWYER J, HASLERLEWIS C M, et al.. Mushrooms and health summit proceedings [J]. J. Nutr., 2014, 144(7): 1128S-1136S. |

| 5 | CHEN L, GONG Y, CAI Y, et al.. Genome sequence of the edible cultivated mushroom Lentinula edodes (Shiitake) reveals insights into lignocellulose degradation [J/OL]. PLoS ONE, 2016, 11(8): e0160336 [2021-10-22]. . |

| 6 | WU F, ZHOU L W, YANG Z L, et al.. Resource diversity of Chinese macrofungi (edible) medicinal and poisonous species [J]. Fungal Divers., 2019, 98: 1-76. |

| 7 | LIU J, JIA L, KAN J, et al.. In vitro and in vivo antioxidant activity of ethanolic extract of white button mushroom (Agaricus bisporus) [J]. Food Chem. Toxicol., 2013, 51: 310-316. |

| 8 | MATTILA P, KÖNKÖ K, EUROLA M, et al.. Contents of vitamins, mineral elements, and some phenolic compounds in cultivated mushrooms [J]. J. Agric. Food Chem., 2001, 49(5): 2343-2348. |

| 9 | TAX E N, COSAN G, ÖTLES S. Optimization of process conditions to improve the quality properties of healthy watermelon snacks developed by hot-air drying [J]. J. Food Meas. Charact., 2021(15): 2146-2160. |

| 10 | 陈新瑶,董星,陈景杰,等.响应曲面法优化猴头菇粗多糖的提取工艺[J].中国农业科技导报,2017,19(3):131-136. |

| CHEN X Y, DONG X, CHEN J J, et al.. Optimization of extraction process for crude polysaccharide from Hericium erinaceus by response surface methodology [J]. J. Agric. Sci. Technol., 2017, 19(3): 131-136. | |

| 11 | 黎斌,彭桂兰,罗传伟,等.油菜籽真空干燥工艺优化[J].食品与发酵工业,2016,42(12):105-110. |

| LI B, PENG G L, LUO C W, et al.. Optimization of rapeseed vacuum drying process [J]. Food Ferment. Ind., 2016, 42(12): 105-110. | |

| 12 | ZHANG W P, CHEN C, PAN Z L, et al.. Vacuum and infrared-assisted hot air impingement drying for improving the processing performance and quality of Poria cocos (Schw.) Wolf Cubes [J/OL]. Foods, 2021, 10(5): 992 [2021-10-22]. . |

| 13 | SHRIVASTAVA A, TRIPATHI A D, PAUL V, et al.. Optimization of spray drying parameters for custard apple (Annona squamosa L.) pulp powder development using response surface methodology (RSM) with improved physicochemical attributes and phytonutrients [J/OL]. LWT-Food Sci. Technol., 2021, 151: 112091 [2021-10-22]. . |

| 14 | YE L, LI Y P, QIN X L, et al.. Evaluation research on agricultural informatization level in tropical areas of China based on entropy method [J]. Appl. Mech. Mater., 2014 (596): 280-285. |

| 15 | 杨伊琳,丁俊雄,吴小华,等.香菇热风干燥特性及动力学模型[J].中国农业大学学报,2022,27(4):135-144. |

| YANG Y L, DING J X, WU X H, et al.. Characteristics of Lentinus edodes hot-air drying and its kinetic model [J]. J. China Agric. Univ., 2022, 27(4): 135-144. | |

| 16 | 于海明.山楂微波热风耦合干燥数学模型研究及干燥设备设计[D].长春:吉林大学,2015. |

| YU H M. Research on mathematical model of microwave hot-air coupling drying of hawthorn and design of drying equipment [D]. Changchun: Jilin University, 2015. | |

| 17 | LAHSASNI S, KOUHILA M, MAHROUZ M, et al.. Thin layer convective solar drying and mathematical modeling of prickly pear peel (Opuntia ficusindica) [J]. Energy, 2004, 29: 211-224. |

| 18 | 陈健凯,林河通,林艺芬,等.基于品质和能耗的杏鲍菇微波真空干燥工艺参数优化[J].农业工程学报,2014,30(3):277-284. |

| CHEN J K, LIN H T, LIN Y F, et al.. Optimization of microwave vacuum drying process parameters of Pleurotus eryngii based on quality and energy consumption [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(3): 277-284. | |

| 19 | 张慧,张裕仁,杨佳,等.响应面法优化香菇热风-微波联合干燥工艺[J].食品工业科技,2019,40(14):214-221, 23. |

| ZHANG H, ZHANG Y R, YANG J, et al.. Response surface methodology to optimize the hot-air-microwave combined drying process of Lentinus edodes [J]. Food Ind. Tech., 2019, 40(14): 214-221, 232. | |

| 20 | 张宁.香菇中的化学成分及相关应用的基础研究[D].天津:天津大学,2013. |

| ZHANG N. Basic research on chemical constituents and related applications in Lentinus edodes [D]. Tianjin: Tianjin University, 2013. | |

| 21 | 王生昌,付迪,陈娟娟,等.基于熵值法的汽车动力性能主观评价指标权重确定方法[J].公路交通科技,2015,32(7):153-158. |

| WANG S C, FU D, CHEN J J, et al.. Method for determining weights of subjective evaluation indexes of automobile power performance based on entropy method [J]. J. Highway Transport. Res. Dev., 2015, 32(7): 153-158. | |

| 22 | KATAYAMA S, SAEKI H. Cooperative effect of relative humidity and glucose concentration on improved solubility of shellfish muscle protein by the Maillard reaction [J]. Fisheries Sci., 2004, 70: 159-166. |

| 23 | FURLAN A L, BIANUCCI E, GIORDANO W, et al.. Proline metabolic dynamics and implications in drought tolerance of peanut plants [J]. Plant Physiol. Biochem., 2020, 151: 566-578. |

| 24 | 赵昕源,欧阳杰,马田田,等.南极磷虾体内主要营养活性物质在热处理过程中的流向[J].水产学报,2021,45(7):1172-1180. |

| ZHAO X Y, OUYANG J, MA T T, et al.. Flow direction of main nutrient substances in Antarctic krill (Euphausia superba) during heat treatment [J]. J. Fish. China, 2021, 45(7): 1172-1180. | |

| 25 | 魏荣男.南极磷虾粉加工工艺的优化[D].上海:上海大学,2017. |

| WEI R N. The optimization of the technology of Antarctic krill powder processing [D]. Shanghai: Shanghai University, 2017. | |

| 26 | YU X L, ZIELINSKA M, JU H Y, et al.. Multistage relative humidity control strategy enhances energy and exergy efficiency of convective drying of carrot cubes [J/OL]. Int. J. Heat Mass Tran., 2020, 149: 119231 [2021-10-22]. . |

| 27 | DOYMAZ I. Drying behaviour of green beans [J]. J. Food Eng., 2005, 69: 161-165. |

| 28 | GIRI S K, PRASAD S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms [J]. J. Food Eng., 2007, 78: 512-521. |

| 29 | ELIK A. Hot air-assisted radio frequency drying of black carrot pomace (kinetics and product quality) [J/OL]. Innov. Food Sci. Emerg., 2021, 73: 102800 [2021-10-22]. . |

| [1] | 张冬梦, 姚栋萍, 吴俊, 罗秋红, 庄文, 刘雄伦, 邓启云, 柏斌. 灌浆期田间自然低温对稻米蒸煮食味品质的影响[J]. 中国农业科技导报, 2023, 25(6): 144-153. |

| [2] | 孙正冉, 张翠萍, 张晋丽, 吴昊, 刘秀艳, 王振凯, 杨玉珍, 贺道华. 喷施化学打顶剂对关中棉区棉花植株生长的影响[J]. 中国农业科技导报, 2023, 25(4): 167-177. |

| [3] | 赵文军, 杨继周, 尹梅, 陈检锋, 薛开政, 胡保文, 付利波, 王伟, 王志远, 杨艳鲜, 陈华. 绿肥模式下减量施氮对烤烟产量与品质的影响[J]. 中国农业科技导报, 2023, 25(4): 189-196. |

| [4] | 王向东, 宋玥, 马艳芝. 不同生姜品种的品质比较与综合评价[J]. 中国农业科技导报, 2023, 25(4): 56-66. |

| [5] | 许娜丽, 余慧霞, 姚明明, 王彦青, 李清峰, 刘彩霞, 孙刚, 陈佳静, 龙姣卉, 王掌军. 基于SSR和SRAP标记小麦资源遗传多样性及农艺性状分析[J]. 中国农业科技导报, 2023, 25(3): 30-46. |

| [6] | 董伟欣, 李东晓, 张月辰. 不同氮素水平对夏玉米生理参数及产量品质的影响[J]. 中国农业科技导报, 2023, 25(1): 142-152. |

| [7] | 陈元伟, 郑华斌, 王慰亲, 旷娜, 罗友谊, 邹丹, 唐启源. 刈割处理对再生稻头季全株生物量、青贮品质和再生季产量的影响[J]. 中国农业科技导报, 2022, 24(8): 161-171. |

| [8] | 张家智, 王文玉, 王兴宇, 张常钰, 石书文, 何雨宣, 周红媛, 刘丽华, 郑桂萍. 不同耕作模式下穴苗数对北方粳稻品质的影响[J]. 中国农业科技导报, 2022, 24(7): 150-158. |

| [9] | 赵晨光, 牛司耘, 陈勋, 方丽, 李海涛, 王佩星, 沈镔镔, 石元值. 复合肥料对茶叶产量、品质及茶园土壤肥力的影响[J]. 中国农业科技导报, 2022, 24(6): 206-217. |

| [10] | 伊六喜, 萨如拉, 范鑫, 赵灿, 李茹, 斯钦巴特尔. 油用亚麻主要品质和农艺性状的变异分析[J]. 中国农业科技导报, 2022, 24(5): 56-67. |

| [11] | 成广雷, 邱军, 王晓光, 徐田军, 陈传永, 张春原, 夏千千, 吴元奇, 赵久然, 王荣焕. 我国青贮玉米组合(品种)的农艺性状、生物产量和品质变化[J]. 中国农业科技导报, 2022, 24(4): 30-37. |

| [12] | 董云萍, 龙宇宙, 林兴军, 莫丽珍, 朱华康, 赵青云, 孙燕. 不同施肥量对小粒咖啡产量、品质及经济效益的影响[J]. 中国农业科技导报, 2022, 24(3): 197-203. |

| [13] | 包奇军, 潘永东, 张华瑜, 柳小宁, 张东佳, 赵锋, 牛小霞, 陈军. 甘肃与欧洲、北美啤酒大麦品种农艺及品质性状比较分析[J]. 中国农业科技导报, 2022, 24(3): 57-66. |

| [14] | 周旋, 杨嫔玲, 彭建伟, 柴慧清, 钟雪梅, 康兴蓉, 龙俊佑, 张慧茹. 功能菌型复合肥减施对结球甘蓝产量、品质及经济效益的影响[J]. 中国农业科技导报, 2022, 24(2): 184-192. |

| [15] | 刘著文, 杨龙飞, 刘茂林, 贾国涛, 姚倩, 马一琼, 崔廷, 杨欣玲, 陈洋, 程良琨. 不同土壤改良剂对土壤养分及烤烟内在品质的影响[J]. 中国农业科技导报, 2022, 24(11): 190-198. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号