Journal of Agricultural Science and Technology ›› 2024, Vol. 26 ›› Issue (6): 82-90.DOI: 10.13304/j.nykjdb.2022.1001

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Guoqiang DUN1,2( ), Xingpeng WU2, Xinxin JI2, Fuli ZHANG1, Wenyi JI3, Yongzhen YANG4

), Xingpeng WU2, Xinxin JI2, Fuli ZHANG1, Wenyi JI3, Yongzhen YANG4

Received:2022-11-17

Accepted:2022-12-29

Online:2024-06-15

Published:2024-06-12

顿国强1,2( ), 吴星澎2, 纪欣鑫2, 张福利1, 纪文义3, 杨永振4

), 吴星澎2, 纪欣鑫2, 张福利1, 纪文义3, 杨永振4

作者简介:顿国强E-mail:dunguoqiangpatent@163.com

基金资助:CLC Number:

Guoqiang DUN, Xingpeng WU, Xinxin JI, Fuli ZHANG, Wenyi JI, Yongzhen YANG. Simulation and Optimization of Soybean Plot Metering Device with Double Swing Plate[J]. Journal of Agricultural Science and Technology, 2024, 26(6): 82-90.

顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90.

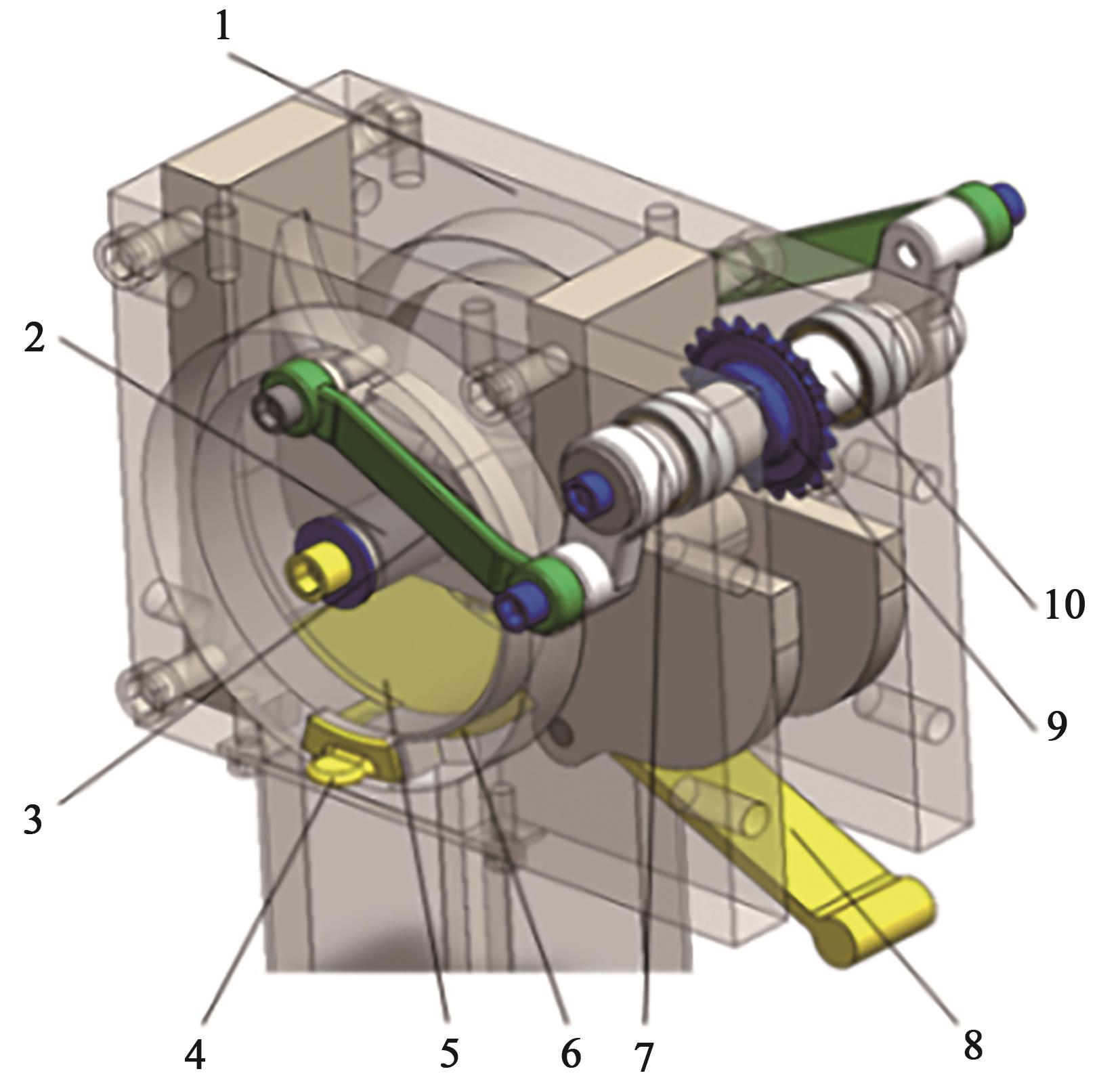

Fig. 1 Structure of seed-metering device of double-swing seed platesNote:1—Seed box; 2—Seed plate shaft; 3—Connecting rod; 4—Hole block; 5—Seed plate; 6—Seed stopping board; 7—Crank; 8—Seed cleaning board; 9—Chain wheel; 10—Drive shaft.

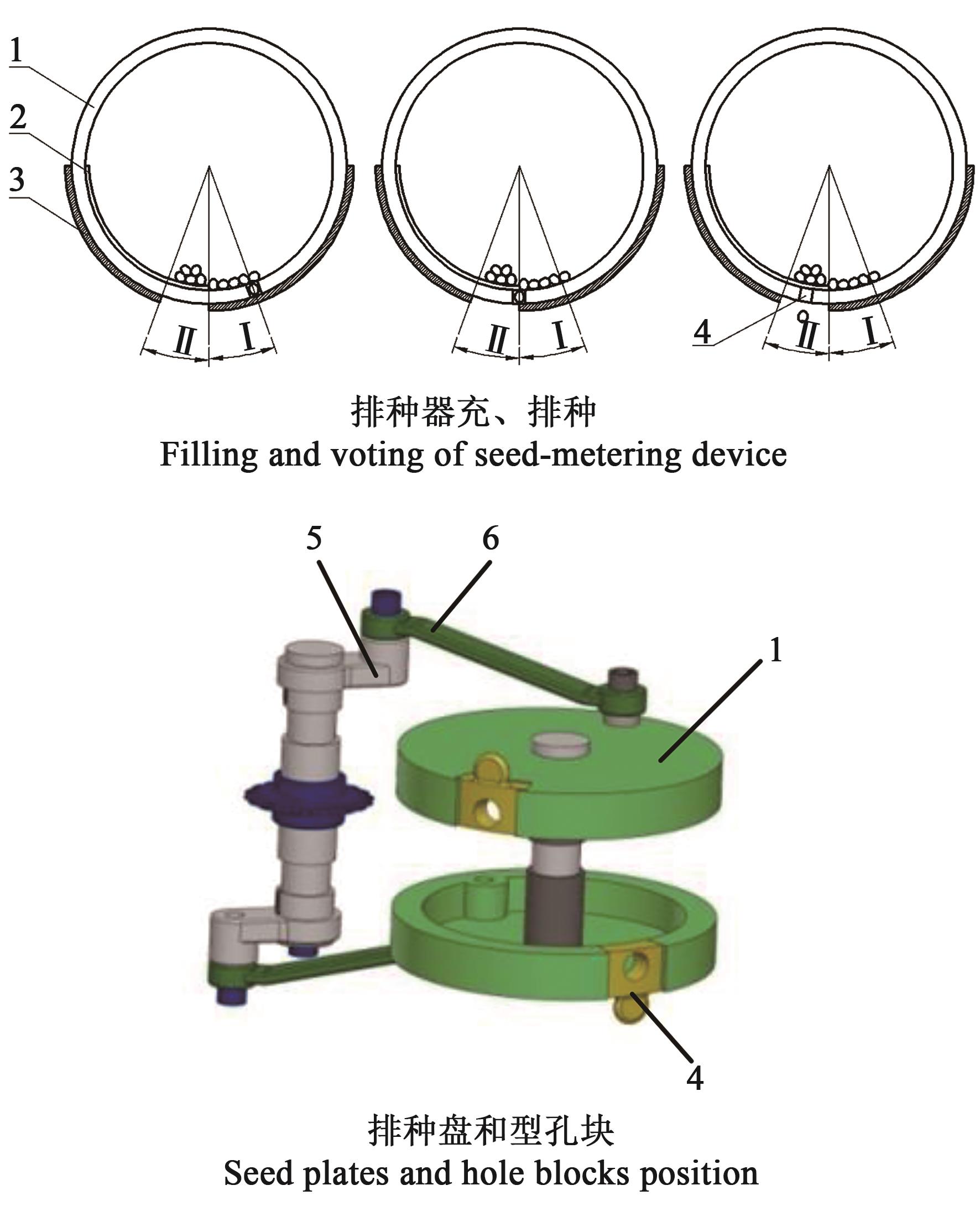

Fig. 2 Working principle of seed-metering device of double-swing seed platesNote:1—Seed plate; 2—Seed stopping board; 3—Shell 4—Hole; 5—Crank; 6—Connecting rod; Ⅰ—Seed filling zone; Ⅱ—Seed voting zone.

Fig. 3 Filling process of the seedNote:r—Radius of the seed of positive sphere, mm; vk—Relative velocity of seed and seed plate, mm·s-1; l—Diameter of the hole, mm;a—Short axis of the ellipsoid seed, mm; b—Long axis of the ellipsoid seed, mm; O—Barycenter of the seed.

项目 Item | 属性 Attribute | 数值 Value |

|---|---|---|

大豆颗粒 Soybean particle | 泊松比 Poisson ratio | 0.25 |

剪切模量 Shear modulus /Pa | 1.04×106 | |

| 密度Density/(kg·m-3) | 1230 | |

塑料 Plastic | 泊松比 Poisson ratio | 0.30 |

剪切模量 Shear modulus /Pa | 1.04×107 | |

| 密度Density/(kg·m-3) | 1290 | |

大豆-大豆 Soybean- soybean | 碰撞恢复系数 Restitution coefficient | 0.60 |

静摩擦系数 Static friction coefficient | 0.45 | |

滚动摩擦系数 Rolling friction coefficient | 0.05 | |

大豆-塑料 Soybean-plastic | 碰撞恢复系数 Restitution coefficient | 0.6 |

静摩擦系数 Static friction coefficient | 0.4 | |

滚动摩擦系数 Rolling friction coefficient | 0.01 |

Table 1 Simulation parameters settings

项目 Item | 属性 Attribute | 数值 Value |

|---|---|---|

大豆颗粒 Soybean particle | 泊松比 Poisson ratio | 0.25 |

剪切模量 Shear modulus /Pa | 1.04×106 | |

| 密度Density/(kg·m-3) | 1230 | |

塑料 Plastic | 泊松比 Poisson ratio | 0.30 |

剪切模量 Shear modulus /Pa | 1.04×107 | |

| 密度Density/(kg·m-3) | 1290 | |

大豆-大豆 Soybean- soybean | 碰撞恢复系数 Restitution coefficient | 0.60 |

静摩擦系数 Static friction coefficient | 0.45 | |

滚动摩擦系数 Rolling friction coefficient | 0.05 | |

大豆-塑料 Soybean-plastic | 碰撞恢复系数 Restitution coefficient | 0.6 |

静摩擦系数 Static friction coefficient | 0.4 | |

滚动摩擦系数 Rolling friction coefficient | 0.01 |

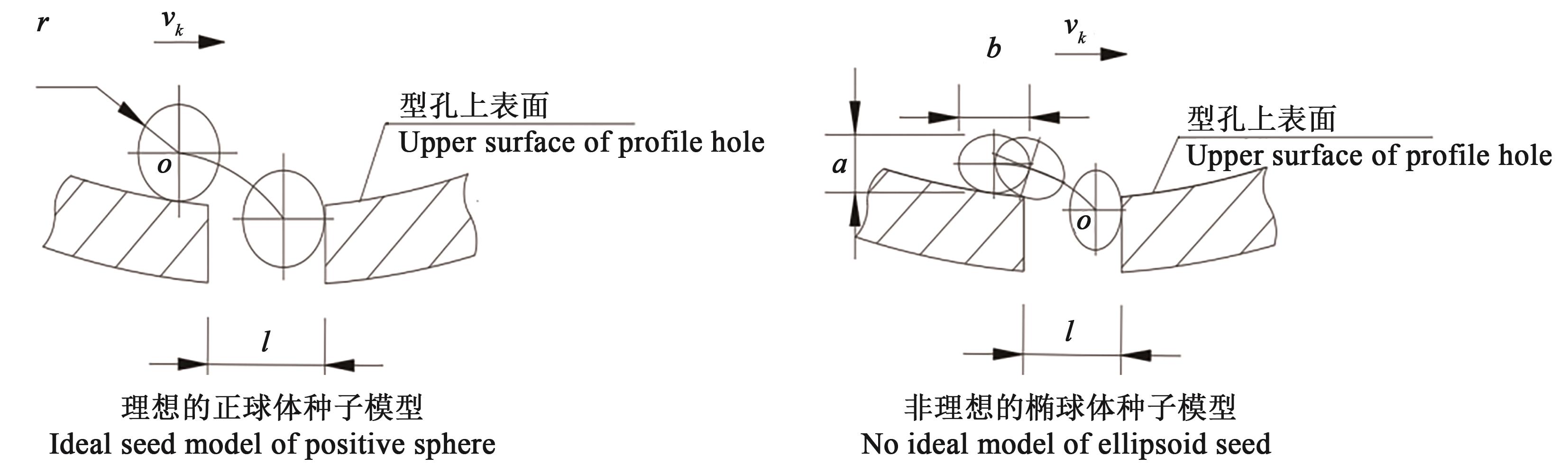

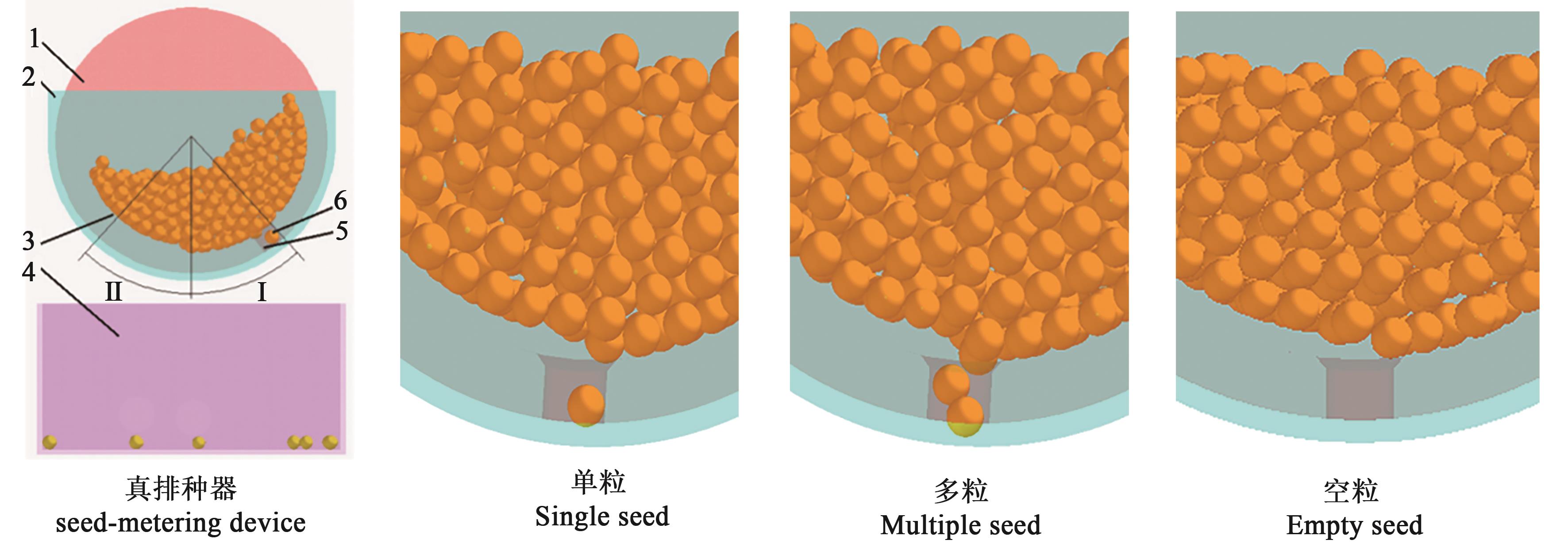

Fig. 4 Simulation process of seed-metering deviceNote:1—Seed plate; 2—Shell; 3—Seed stopping board; 4—Seed collection box; 5—Hole; 6—Soybean particle; Ⅰ—Seed filling zone; Ⅱ—Seed voting zone.

水平 Level | x1:型孔孔径 Hole diameter/mm | x2:摆动频率 Swing frequency/Hz |

|---|---|---|

| 1.414 | 10.00 | 2.00 |

| 1 | 9.71 | 1.78 |

| 0 | 9.00 | 1.25 |

| -1 | 8.29 | 0.72 |

| -1.414 | 8.00 | 0.50 |

Table 2 Factors and levels of test

水平 Level | x1:型孔孔径 Hole diameter/mm | x2:摆动频率 Swing frequency/Hz |

|---|---|---|

| 1.414 | 10.00 | 2.00 |

| 1 | 9.71 | 1.78 |

| 0 | 9.00 | 1.25 |

| -1 | 8.29 | 0.72 |

| -1.414 | 8.00 | 0.50 |

| 序号Code | x1:型孔孔径 Hole diameter | x2:摆动频率 Swing frequency | Y1:单粒率 Single-seed rate/% | Y2:多粒率 Multi-seed rate/% | Y3:空粒率 Empty-seed rate/% |

|---|---|---|---|---|---|

| 1 | -1 | -1 | 63 | 9 | 28 |

| 2 | 1 | -1 | 84 | 16 | 0 |

| 3 | -1 | 1 | 67 | 10 | 23 |

| 4 | 1 | 1 | 64 | 16 | 20 |

| 5 | -1.414 | 0 | 62 | 8 | 30 |

| 6 | 1.414 | 0 | 68 | 16 | 16 |

| 7 | 0 | -1.414 | 74 | 12 | 14 |

| 8 | 0 | 1.414 | 60 | 15 | 25 |

| 9 | 0 | 0 | 72 | 11 | 17 |

| 10 | 0 | 0 | 77 | 13 | 10 |

| 11 | 0 | 0 | 78 | 13 | 9 |

| 12 | 0 | 0 | 75 | 14 | 11 |

| 13 | 0 | 0 | 70 | 14 | 16 |

Table 3 Results of simulation test

| 序号Code | x1:型孔孔径 Hole diameter | x2:摆动频率 Swing frequency | Y1:单粒率 Single-seed rate/% | Y2:多粒率 Multi-seed rate/% | Y3:空粒率 Empty-seed rate/% |

|---|---|---|---|---|---|

| 1 | -1 | -1 | 63 | 9 | 28 |

| 2 | 1 | -1 | 84 | 16 | 0 |

| 3 | -1 | 1 | 67 | 10 | 23 |

| 4 | 1 | 1 | 64 | 16 | 20 |

| 5 | -1.414 | 0 | 62 | 8 | 30 |

| 6 | 1.414 | 0 | 68 | 16 | 16 |

| 7 | 0 | -1.414 | 74 | 12 | 14 |

| 8 | 0 | 1.414 | 60 | 15 | 25 |

| 9 | 0 | 0 | 72 | 11 | 17 |

| 10 | 0 | 0 | 77 | 13 | 10 |

| 11 | 0 | 0 | 78 | 13 | 9 |

| 12 | 0 | 0 | 75 | 14 | 11 |

| 13 | 0 | 0 | 70 | 14 | 16 |

评价指标 Evaluation index | 来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

单粒率 Single-seed rate | 模型Model | 531.95 | 5 | 106.39 | 8.99 | 0.005 9 | ** |

| x1 | 87.68 | 1 | 87.68 | 7.41 | 0.029 7 | * | |

| x2 | 160.20 | 1 | 160.20 | 13.54 | 0.007 9 | ** | |

| x1x2 | 144.00 | 1 | 144.00 | 12.17 | 0.010 1 | * | |

| x12 | 101.78 | 1 | 101.78 | 8.60 | 0.021 9 | * | |

| x22 | 55.52 | 1 | 55.52 | 4.69 | 0.067 0 | ||

| 残差Residual | 82.82 | 7 | 11.83 | ||||

| 失拟项Lack of fit | 37.62 | 3 | 12.54 | 1.11 | 0.443 2 | ||

| 纯误差Pure error | 45.20 | 4 | 11.30 | ||||

| 总和Total | 614.77 | 12 | |||||

多粒率 Multi-seed rate | 模型Model | 77.33 | 2 | 38.67 | 37.31 | < 0.000 1 | ** |

| x1 | 73.89 | 1 | 73.89 | 67.44 | < 0.000 1 | ** | |

| x2 | 3.44 | 1 | 3.44 | 3.32 | 0.098 6 | ||

| 残差Residual | 7.67 | 10 | 1.04 | ||||

| 失拟项Lack of fit | 4.36 | 6 | 0.73 | 0.48 | 0.795 8 | ||

| 纯误差Pure error | 6.00 | 4 | 1.50 | ||||

| 总和Total | 87.69 | 12 |

Table 4 Results of variance analysis

评价指标 Evaluation index | 来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

单粒率 Single-seed rate | 模型Model | 531.95 | 5 | 106.39 | 8.99 | 0.005 9 | ** |

| x1 | 87.68 | 1 | 87.68 | 7.41 | 0.029 7 | * | |

| x2 | 160.20 | 1 | 160.20 | 13.54 | 0.007 9 | ** | |

| x1x2 | 144.00 | 1 | 144.00 | 12.17 | 0.010 1 | * | |

| x12 | 101.78 | 1 | 101.78 | 8.60 | 0.021 9 | * | |

| x22 | 55.52 | 1 | 55.52 | 4.69 | 0.067 0 | ||

| 残差Residual | 82.82 | 7 | 11.83 | ||||

| 失拟项Lack of fit | 37.62 | 3 | 12.54 | 1.11 | 0.443 2 | ||

| 纯误差Pure error | 45.20 | 4 | 11.30 | ||||

| 总和Total | 614.77 | 12 | |||||

多粒率 Multi-seed rate | 模型Model | 77.33 | 2 | 38.67 | 37.31 | < 0.000 1 | ** |

| x1 | 73.89 | 1 | 73.89 | 67.44 | < 0.000 1 | ** | |

| x2 | 3.44 | 1 | 3.44 | 3.32 | 0.098 6 | ||

| 残差Residual | 7.67 | 10 | 1.04 | ||||

| 失拟项Lack of fit | 4.36 | 6 | 0.73 | 0.48 | 0.795 8 | ||

| 纯误差Pure error | 6.00 | 4 | 1.50 | ||||

| 总和Total | 87.69 | 12 |

评价指标 Evaluation index | 来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

空粒率 Empty-seed rate | 模型Model | 754.27 | 5 | 150.85 | 11.30 | 0.003 0 | ** |

| x1 | 322.57 | 1 | 322.57 | 24.17 | 0.001 7 | ** | |

| x2 | 116.71 | 1 | 116.71 | 8.75 | 0.021 2 | * | |

| x1x2 | 156.25 | 1 | 156.25 | 11.71 | 0.011 1 | * | |

| x12 | 130.13 | 1 | 130.13 | 9.75 | 0.016 8 | * | |

| x22 | 46.13 | 1 | 46.13 | 3.46 | 0.105 4 | ||

| 残差Residual | 93.42 | 7 | 13.35 | ||||

| 失拟项Lack of fit | 40.22 | 3 | 13.41 | 1.01 | 0.476 2 | ||

| 纯误差Pure error | 53.20 | 4 | 13.30 | ||||

| 总和Total | 847.69 | 12 |

Table 4 Results of variance analysis

评价指标 Evaluation index | 来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

空粒率 Empty-seed rate | 模型Model | 754.27 | 5 | 150.85 | 11.30 | 0.003 0 | ** |

| x1 | 322.57 | 1 | 322.57 | 24.17 | 0.001 7 | ** | |

| x2 | 116.71 | 1 | 116.71 | 8.75 | 0.021 2 | * | |

| x1x2 | 156.25 | 1 | 156.25 | 11.71 | 0.011 1 | * | |

| x12 | 130.13 | 1 | 130.13 | 9.75 | 0.016 8 | * | |

| x22 | 46.13 | 1 | 46.13 | 3.46 | 0.105 4 | ||

| 残差Residual | 93.42 | 7 | 13.35 | ||||

| 失拟项Lack of fit | 40.22 | 3 | 13.41 | 1.01 | 0.476 2 | ||

| 纯误差Pure error | 53.20 | 4 | 13.30 | ||||

| 总和Total | 847.69 | 12 |

| 项目Item | 标准要求Standard requirements/% | 台架试验结果Bench test results/% | 田间试验结果Field test results/% |

|---|---|---|---|

| 合格指数Qualified index | >60 | 75.5 | 71.4 |

| 重播指数Multiples index | <30 | 16.9 | 18.8 |

| 漏播指数Miss index | <15 | 7.6 | 9.8 |

Table 5 Results of test

| 项目Item | 标准要求Standard requirements/% | 台架试验结果Bench test results/% | 田间试验结果Field test results/% |

|---|---|---|---|

| 合格指数Qualified index | >60 | 75.5 | 71.4 |

| 重播指数Multiples index | <30 | 16.9 | 18.8 |

| 漏播指数Miss index | <15 | 7.6 | 9.8 |

| 1 | 周家鹏, 王延耀. 小区播种机净种系统的研究[J]. 农机化研究, 2016, 38(10): 109-113. |

| ZHOU J P, WANG Y Y. Plot seeder seed-clearing system research [J]. J. Agric. Mechan. Res., 2016, 38(10): 109-113. | |

| 2 | 常建国, 刘兴博, 叶彤, 等. 农业小区田间育种试验机械的现状及发展[J]. 农机化研究, 2011, 33(2): 238-241. |

| CHANG J G, LIU X B, YE T, et al.. Agricultural plot field trial breeding status and development of machuinery [J]. J. Agric. Mech. Res., 2011, 33(2): 238-241. | |

| 3 | 王琛, 刘扬, 段俊兆, 等. 育种试验小区播种机排种器性能及应用分析[J]. 农业机械, 2012(28): 124-126. |

| WANG C, LIU Y, DUAN J Z, et al.. Performance and application analysis of seeder arrangement in breeding test plot [J]. Farm Mach, 2012(28): 124-126. | |

| 4 | 刘曙光, 尚书旗, 杨然兵, 等. 小区播种机的发展分析[J]. 农机化研究, 2011, 33(3): 237-241. |

| LIU S G, SHANG S Q, YANG R B, et al.. Analysis of plot seeder development [J]. J. Agric. Mechan. Res., 2011,33(3):237-2 41. | |

| 5 | 宋江腾, 张淑敏. 小区播种机的研究现状及发展方向[J]. 农机化研究, 2004(4): 14-16. |

| SONG J T, ZHANG S M. Current situation and development orientation of plot seeder [J]. J. Agric. Mech. Res., 2004(4): 14-16. | |

| 6 | 杨薇, 王飞, 赫志飞, 等. 小区育种机械发展现状及展望[J].农业工程, 2014, 4(6):7-9, 56. |

| YANG W, WANG F, HE Z F, et al.. Development present situation and prospect of plot breeding machinery [J]. Agic. Eng., 2014, 4(6): 7-9, 56. | |

| 7 | 刘宏新, 刘俊孝, 唐师法, 等. 对置斜盘高速精密大豆排种器设计与充种机理分析[J]. 农业工程学报, 2016, 32(20): 24-31. |

| LIU H X, LIU J X, TANG S F, et al.. Design on opposed inclined-plate high-speed precision seed-metering device and its working mechanism analysis [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(20): 24-31. | |

| 8 | 刘龙, 安雪, 余永昌, 等. 基于电控自动净种窝眼轮式大豆播种器的设计与试验[J]. 农机化研究, 2021, 43(7): 58-63. |

| LIU L, AN X, YU Y C, et al.. Design and experiment of automatic seed-clearing wheel-type soybean seeder based on electronic control [J]. J. Agric. Mech. Res., 2021, 43(7): 58-63. | |

| 9 | 贾洪雷, 赵佳乐, 郭明卓, 等. 双凹面摇杆式排种器设计与性能试验[J]. 农业机械学报, 2015, 46(1): 60-65+72. |

| JIA H L, ZHAO J L, GUO M Z, et al.. Design and performance experiment on double-concave surface rocker type seed metering device [J]. Trans. Chin. Soc. Agric. Mach., 2015, 46(1):60-65+72. | |

| 10 | 姜峰, 陈海涛, 王业成. 小区育种插装式排种器的设计[J]. 农业工程学报, 2010, 26(S1): 9-12. |

| JING F, CHEN H T, WANG Y C. Design of insert-metering device for subdistrict breeding seeder [J]. Trans. Chin. Soc. Agric. Eng., 2010, 26(S1): 9-12. | |

| 11 | 黄珊珊, 陈海涛, 王业成. 插装式大豆小区播种机排种系统预充种清种机构的设计[J]. 大豆科学, 2017, 36(4): 626-631. |

| HUANG S S, CHEN H T, WANG Y C. Design on the pro filling seed-clearing institution of insert-metering system for soybean sub-distrct seeder [J]. Soybean Sci., 2017, 36(4): 626-631. | |

| 12 | 顿国强, 毛宁, 刘文辉,等. 四杆平移式大豆小区育种排种器设计与试验[J]. 农业机械学报, 2022, 53(4): 70-78. |

| DUN G Q, MAO N, LIU W H, et al.. Design and experiment of four-bar translational seed metering device for soybean plot breeding [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(4): 70-78. | |

| 13 | 顿国强, 杨永振, 郭艳玲, 等. 不同品种大豆种子充填特性的EDEM仿真分析[J]. 河南农业大学学报, 2019, 53(1): 93-98. |

| DUN G Q, YANG Y Z, GUO Y L, et al.. Analysis of edem simulation of different soybean seed filling characteristics [J], J. Henan Agric.Univ., 2019, 53(1): 93-98. | |

| 14 | 王瑞芳, 李占勇, 窦如彪, 等. 水平转筒内大豆颗粒随机运动与混合特性模拟[J].农业机械学报, 2013, 44(6): 93-99. |

| WANG R F, LI Z Y, DOU R B, et al.. Simulation on random mo-tion and mixing characteristic for soybean in rotary drum [J]. Trans. Chin. Soc. Agric. Mach., 2013,44(6): 93-99. | |

| 15 | 张婷婷, 尚书旗, 王东伟. 六行同步小区条播机的研制[J]. 农机化研究, 2017, 39(5): 144-149. |

| ZHANG T T, SHANG S Q, WANG D W. Design of six lines synchronous plot seeder [J]. J. Agric. Mechan. Res., 2017, 39(5): 144-149. | |

| 16 | 陶桂香, 衣淑娟, 汪春, 等. 水稻钵盘精量播种机充种性能试验[J]. 农业工程学报, 2013, 29(08): 44-50. |

| TAO G X, YI S J, WANG C, et al.. Performance experiments of bowl dish precision seeder for rice in fillingprocessing [J]. Trans. Chin. Soc. Agric. Eng., 2013, 29(8):44-50. | |

| 17 | 曹秀英, 廖庆喜, 丛锦玲, 等. 离心式油菜精量排种器型孔结构设计与试验[J]. 农业机械学报, 2014, 45(S1): 40-46. |

| CAO X Y, LIAO Q X, CONG J L, et al.. Design and experiment on metering hole structure of centrifugal precision metering device for rapeseed [J]. Trans. Chin. Soc. Agric. Mach., 2014, 45(S1):40-46. | |

| 18 | 牟忠秋, 衣淑娟, 李衣菲, 等. 气吸式玉米精量排种器性能试验研究[J]. 农机化研究, 2019, 41(5): 142-147. |

| MOU Z Q, YI S J, LI Y F, et al.. Experimental study on the performance of air-suction corn precision seeding [J]. J. Agric. Mechan. Res., 2019(5): 142-147. | |

| 19 | 史嵩, 张东兴, 杨丽, 等. 基于EDEM软件的气压组合孔式排种器充种性能模拟与验证[J]. 农业工程学报, 2015, 31(3): 62-69. |

| SHI S, ZHANG D X, YANG L, et al.. Simulation and erify-cation of seed-filling performance of pneumatic-combined holesmaize precision seed-metering device based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(3): 62-69. | |

| 20 | 郝文录, 刘恒新, 张维和, 等. 播种机质量评价技术规范: [S]. 北京: 中国标准出版社, 2006. |

| [1] | Wenyue WANG, Zhipeng YAO, Yang YU, Yiqiang GE. Scientific and Technological Innovation of Soybean Seed Industry in China:Current Situation and Strategy [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 1-6. |

| [2] | Yuanhao HUANG, Lazhen QUAN, Guangfa HU, Wei QUAN, Fanggang SHI. Calibration of Discrete Element Contact Parameters for Various Materials and Soils with Different Moisture Content [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 98-109. |

| [3] | Lin CHEN, Nanhui YU, Lizong WANG, Jijun FAN, Gang LEI, Xiaopeng LIU, Long ZHOU, Jin ZHOU. Measurement of Contact Parameters and Discrete Element Simulation Calibration of Rice Bran and Broken Rice [J]. Journal of Agricultural Science and Technology, 2024, 26(2): 127-136. |

| [4] | Jianmin YAO, Junkui MA, Zhongxiang WANG, Xinyuan BI, Ruizhen LI, Ruiping YANG, Zhao LIU, Fenghui GUO. Application Effect of Full Biodegradable Water Permeable Plastic Film in Soybean-Maize Belt Composite Planting [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 178-185. |

| [5] | Rui TIAN, Hua ZHANG, Meihong HUANG, Zhenqi SHAO, Xihuan LI, Caiying ZHANG. Mining of Candidate Genes and Genetic Loci Conferring Drought Tolerance in Soybean [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 69-82. |

| [6] | Chenyang ZHANG, Minggang XU, Fei WANG, Ran LI, Nan SUN. Effects of Manure Application on Soybean Yield and Soil Nutrients in China [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 148-156. |

| [7] | Boyang KE, Wenlong LI, Caiying ZHANG. Expressions of SWEET Genes During Pod and Seed Developments and Under Different Stress Conditions in Soybean [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 33-52. |

| [8] | Yaqian SUN, Shiliang CHEN, Jiahao CHU, Xihuan LI, Caiying ZHANG. Mining of QTLs and Candidate Genes for Pod and Seed Traits via Combining BSA-seq and Linkage Mapping in Soybean [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 29-42. |

| [9] | Jian HU, Gang CHE, Lin WAN, Huiru ZHOU, Guang LI. Study of Soybean Row Line Extraction Method Under High Light Conditions [J]. Journal of Agricultural Science and Technology, 2023, 25(5): 106-111. |

| [10] | Zitao MA, Zhihao ZHAO, Wei QUAN, Fanggang SHI, Chen GAO, Mingliang WU. Calibration of Discrete Element Parameter of Rice Stubble Straw Based on EDEM [J]. Journal of Agricultural Science and Technology, 2023, 25(11): 103-113. |

| [11] | Zhenqi SHAO, Wenlong LI, Youbin KONG, Hui DU, Zhanjun LI, Xihuan LI, Caiying ZHANG. Identification of Soybean Quality Traits and Screening of Elite Germplasms in Huang-Huai-Hai Ecoregion [J]. Journal of Agricultural Science and Technology, 2023, 25(11): 58-69. |

| [12] | Zhanwu YANG, Hui DU, Xinzhu XING, Wenlong LI, Youbin KONG, Xihuan LI, Caiying ZHANG. Functional Analysis of Cytochrome P450 Family GmCYP78A71 in Soybean Nodulation [J]. Journal of Agricultural Science and Technology, 2023, 25(1): 50-57. |

| [13] | Feixiang LI, Peng WANG, Yunfei WANG, Yuefeng GE, Kaiyi TANG, Dezhi LI. Calibration of Discrete Element Parameters of Corn Coated Seeds Based on Stacking Test [J]. Journal of Agricultural Science and Technology, 2022, 24(7): 97-107. |

| [14] | Zhenxiang TIAN, Wei DING, Zhuo CHENG, Hangyu DAI. Isolation of Endophytic Bacteria in Soybean and Its Action Effect [J]. Journal of Agricultural Science and Technology, 2022, 24(6): 47-57. |

| [15] | Jianwei YAN, Song WEI, Dongjun HU, Qihe LIU, Fuigui ZHANG. Parameter Calibration of Radish Seeds with Different Filling Particle Radius by DEM [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 119-128. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号