Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (10): 99-108.DOI: 10.13304/j.nykjdb.2022.0405

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Yuyue LIANG1,2( ), Kan ZHENG2, Junfang XIA2(

), Kan ZHENG2, Junfang XIA2( )

)

Received:2022-05-16

Accepted:2022-07-23

Online:2023-10-15

Published:2023-10-27

Contact:

Junfang XIA

通讯作者:

夏俊芳

作者简介:梁玉玥 E-mail: 274655882@qq.com;

基金资助:CLC Number:

Yuyue LIANG, Kan ZHENG, Junfang XIA. Performance Simulation and Experiment on Detection and Seed Blowing Device for Rice and Wheat Seeding Device[J]. Journal of Agricultural Science and Technology, 2023, 25(10): 99-108.

梁玉玥, 郑侃, 夏俊芳. 稻麦兼用排种器检测与吹种装置性能模拟与试验[J]. 中国农业科技导报, 2023, 25(10): 99-108.

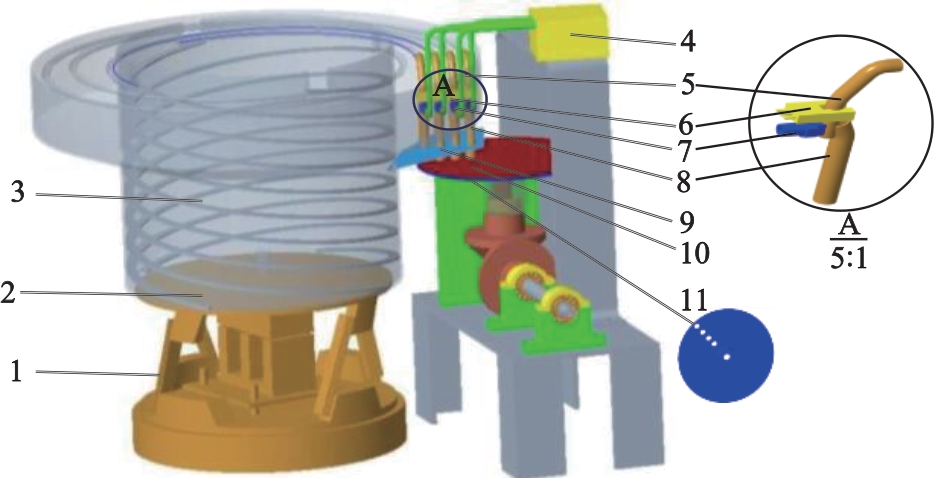

Fig. 1 Structure of seed metering deviceNote:1—Seed supply device; 2—Hopper; 3—Spiral guide; 4—Solenoid valve; 5—Sorting tube; 6—Photoelectric sensor; 7—Blow nozzle valve; 8—Seed filling tube; 9—Tank return seed; 10—Up seed plate; 11—Lower seed plate.

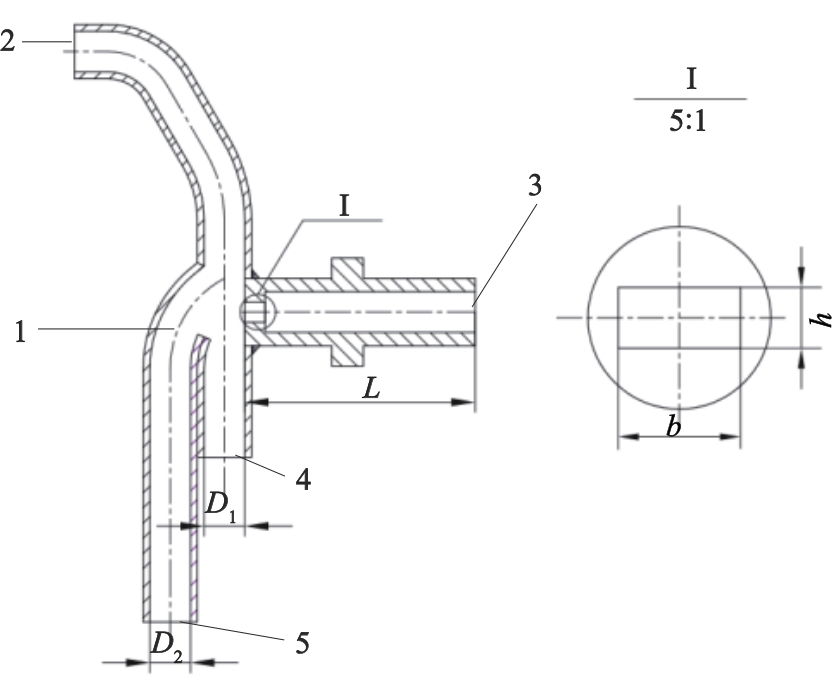

Fig. 3 Blowing deviceNote:1—Gas-solid two phase flow mixing pipeline; 2—Seeds entrance; 3—Air inlet; 4—Parting outlet; 5—Gas-solid two phase flow outlet.

| 喷嘴 Nozzle tube | 长度 Length | 宽度 Width | 高度 Height |

|---|---|---|---|

| Type 1 | 18 | 5 | 5 |

| Type 2 | 18 | 6 | 4 |

| Type 3 | 18 | 7 | 3 |

Table 1 Structural parameters of nozzle tubes with different cross-sectional areas

| 喷嘴 Nozzle tube | 长度 Length | 宽度 Width | 高度 Height |

|---|---|---|---|

| Type 1 | 18 | 5 | 5 |

| Type 2 | 18 | 6 | 4 |

| Type 3 | 18 | 7 | 3 |

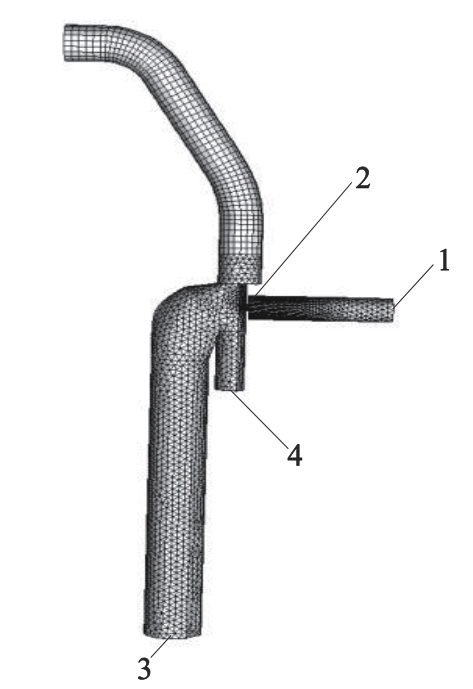

Fig. 5 Grid of blowing-deviceNote:1—Air pressure inlet; 2—Air velocity inlet; 3—Gas-solid two phase flow pressure outlet; 4—Discharge pressure outlet.

| 水平 Level | 气流入口压力 Air inlet pressure/Pa | 工作转速 Working speed/(r∙min-1) |

|---|---|---|

| 1 | 100 | 12 |

| 2 | 300 | 20 |

| 3 | 500 | 28 |

Table 2 Simulation test design level

| 水平 Level | 气流入口压力 Air inlet pressure/Pa | 工作转速 Working speed/(r∙min-1) |

|---|---|---|

| 1 | 100 | 12 |

| 2 | 300 | 20 |

| 3 | 500 | 28 |

| 气流入口压力 Air inlet pressure/Pa | 工作转速 Working speed/(r∙min-1) | 水稻响应值 Rice response value/N | 小麦响应值 Wheat response value/N | ||||

|---|---|---|---|---|---|---|---|

| Fz | Fx | FP | Fz | Fx | FP | ||

| 100 | 12 | 2.03×10-4 | 2.17×10-3 | 2.18×10-3 | 8.75×10-5 | 9.76×10-4 | 9.80×10-4 |

| 300 | 12 | 2.07×10-4 | 3.21×10-3 | 3.22×10-3 | 9.06×10-5 | 1.64×10-3 | 1.64×10-3 |

| 500 | 12 | 2.13×10-4 | 4.24×10-3 | 4.25×10-3 | 9.41×10-5 | 3.01×10-3 | 3.01×10-3 |

| 100 | 20 | 2.07×10-4 | 2.23×10-3 | 2.24×10-3 | 1.13×10-4 | 7.01×10-4 | 7.10×10-4 |

| 300 | 20 | 2.16×10-4 | 3.41×10-3 | 3.42×10-3 | 1.26×10-4 | 2.44×10-3 | 2.45×10-3 |

| 500 | 20 | 2.18×10-4 | 5.37×10-3 | 5.47×10-3 | 1.19×10-4 | 3.82×10-3 | 3.85×10-3 |

| 100 | 28 | 2.21×10-4 | 2.25×10-3 | 2.28×10-3 | 1.24×10-4 | 1.32×10-3 | 1.35×10-3 |

| 300 | 28 | 2.34×10-4 | 4.36×10-3 | 4.36×10-3 | 1.31×10-4 | 3.98×10-3 | 4.00×10-3 |

| 500 | 28 | 2.28×10-4 | 6.51×10-3 | 6.53×10-3 | 1.28×10-4 | 5.38×10-3 | 5.39×10-3 |

Table 3 Seed stress under different airflow inlet pressure and working speed

| 气流入口压力 Air inlet pressure/Pa | 工作转速 Working speed/(r∙min-1) | 水稻响应值 Rice response value/N | 小麦响应值 Wheat response value/N | ||||

|---|---|---|---|---|---|---|---|

| Fz | Fx | FP | Fz | Fx | FP | ||

| 100 | 12 | 2.03×10-4 | 2.17×10-3 | 2.18×10-3 | 8.75×10-5 | 9.76×10-4 | 9.80×10-4 |

| 300 | 12 | 2.07×10-4 | 3.21×10-3 | 3.22×10-3 | 9.06×10-5 | 1.64×10-3 | 1.64×10-3 |

| 500 | 12 | 2.13×10-4 | 4.24×10-3 | 4.25×10-3 | 9.41×10-5 | 3.01×10-3 | 3.01×10-3 |

| 100 | 20 | 2.07×10-4 | 2.23×10-3 | 2.24×10-3 | 1.13×10-4 | 7.01×10-4 | 7.10×10-4 |

| 300 | 20 | 2.16×10-4 | 3.41×10-3 | 3.42×10-3 | 1.26×10-4 | 2.44×10-3 | 2.45×10-3 |

| 500 | 20 | 2.18×10-4 | 5.37×10-3 | 5.47×10-3 | 1.19×10-4 | 3.82×10-3 | 3.85×10-3 |

| 100 | 28 | 2.21×10-4 | 2.25×10-3 | 2.28×10-3 | 1.24×10-4 | 1.32×10-3 | 1.35×10-3 |

| 300 | 28 | 2.34×10-4 | 4.36×10-3 | 4.36×10-3 | 1.31×10-4 | 3.98×10-3 | 4.00×10-3 |

| 500 | 28 | 2.28×10-4 | 6.51×10-3 | 6.53×10-3 | 1.28×10-4 | 5.38×10-3 | 5.39×10-3 |

| 作物 Crop | 方差来源 Source of variance | 平方和 Sum of squared | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 水稻 Rice | 工作转速 Working speed/(r∙min-1) | 1.37×10-5 | 2 | 35.01 | 0.002 9** |

| 入口压力 Air inlet pressure/Pa | 2.81×10-6 | 2 | 7.22 | 0.047 1* | |

| 误差 Error | 7.80×10-7 | 4 | |||

| 总和 Sum | 1.72×10-5 | 8 | |||

| 小麦 Wheat | 工作转速 Working speed/(r∙min-1) | 1.42×10-5 | 2 | 21.20 | 0.007 4** |

| 入口压力 Air inlet pressure/Pa | 4.66×10-6 | 2 | 6.97 | 0.049 8* | |

| 误差 Error | 1.34×10-6 | 4 | |||

| 总和 Sum | 2.02×10-5 | 8 |

Table 4 Variance analysis on various factors on force

| 作物 Crop | 方差来源 Source of variance | 平方和 Sum of squared | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 水稻 Rice | 工作转速 Working speed/(r∙min-1) | 1.37×10-5 | 2 | 35.01 | 0.002 9** |

| 入口压力 Air inlet pressure/Pa | 2.81×10-6 | 2 | 7.22 | 0.047 1* | |

| 误差 Error | 7.80×10-7 | 4 | |||

| 总和 Sum | 1.72×10-5 | 8 | |||

| 小麦 Wheat | 工作转速 Working speed/(r∙min-1) | 1.42×10-5 | 2 | 21.20 | 0.007 4** |

| 入口压力 Air inlet pressure/Pa | 4.66×10-6 | 2 | 6.97 | 0.049 8* | |

| 误差 Error | 1.34×10-6 | 4 | |||

| 总和 Sum | 2.02×10-5 | 8 |

| 气流入口压力 Air inlet pressure/Pa | 工作转速 Working speed/(r∙min-1) | 水稻响应值 Rice response value/(m∙s-1) | 小麦响应值 Wheat response value/(m∙s-1) | ||||

|---|---|---|---|---|---|---|---|

| vx | vz | vp | vx | vz | vp | ||

| 100 | 12 | 20.14 | 1.04 | 20.17 | 22.22 | 1.13 | 22.25 |

| 300 | 12 | 23.51 | 1.19 | 23.54 | 25.76 | 1.24 | 25.79 |

| 500 | 12 | 26.68 | 1.25 | 26.71 | 28.98 | 1.28 | 29.01 |

| 100 | 20 | 23.42 | 1.43 | 23.46 | 24.10 | 1.45 | 24.14 |

| 300 | 20 | 27.92 | 1.48 | 26.57 | 28.58 | 1.54 | 28.62 |

| 500 | 20 | 29.30 | 1.52 | 29.34 | 30.99 | 1.63 | 31.03 |

| 100 | 28 | 26.29 | 1.67 | 26.34 | 27.40 | 1.82 | 27.46 |

| 300 | 28 | 28.76 | 1.74 | 28.81 | 30.79 | 1.79 | 30.84 |

| 500 | 28 | 30.67 | 1.75 | 30.72 | 33.10 | 1.88 | 33.15 |

Table 5 Mean velocity under different airflow inlet pressure and working speed

| 气流入口压力 Air inlet pressure/Pa | 工作转速 Working speed/(r∙min-1) | 水稻响应值 Rice response value/(m∙s-1) | 小麦响应值 Wheat response value/(m∙s-1) | ||||

|---|---|---|---|---|---|---|---|

| vx | vz | vp | vx | vz | vp | ||

| 100 | 12 | 20.14 | 1.04 | 20.17 | 22.22 | 1.13 | 22.25 |

| 300 | 12 | 23.51 | 1.19 | 23.54 | 25.76 | 1.24 | 25.79 |

| 500 | 12 | 26.68 | 1.25 | 26.71 | 28.98 | 1.28 | 29.01 |

| 100 | 20 | 23.42 | 1.43 | 23.46 | 24.10 | 1.45 | 24.14 |

| 300 | 20 | 27.92 | 1.48 | 26.57 | 28.58 | 1.54 | 28.62 |

| 500 | 20 | 29.30 | 1.52 | 29.34 | 30.99 | 1.63 | 31.03 |

| 100 | 28 | 26.29 | 1.67 | 26.34 | 27.40 | 1.82 | 27.46 |

| 300 | 28 | 28.76 | 1.74 | 28.81 | 30.79 | 1.79 | 30.84 |

| 500 | 28 | 30.67 | 1.75 | 30.72 | 33.10 | 1.88 | 33.15 |

| 作物 Crop | 方差来源 Source of variance | 平方和 Sum of squared | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 水稻 Rice | 工作转速 Working speed/(r∙min-1) | 47.11 | 2 | 76.21 | 0.000 7** |

| 入口压力 Air inlet pressure/Pa | 40.12 | 2 | 64.91 | 0.000 9** | |

| 误差 Error | 1.24 | 4 | |||

| 总和 Sum | 88.46 | 8 | |||

| 小麦 Wheat | 工作转速 Working speed/(r∙min-1) | 63.00 | 2 | 182.47 | 0.000 1** |

| 入口压力 Air inlet pressure/Pa | 34.61 | 2 | 100.22 | 0.000 3** | |

| 误差 Error | 0.69 | 4 | |||

| 总和 Sum | 98.30 | 8 |

Table 6 Variance analysis on various factors on velocity

| 作物 Crop | 方差来源 Source of variance | 平方和 Sum of squared | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 水稻 Rice | 工作转速 Working speed/(r∙min-1) | 47.11 | 2 | 76.21 | 0.000 7** |

| 入口压力 Air inlet pressure/Pa | 40.12 | 2 | 64.91 | 0.000 9** | |

| 误差 Error | 1.24 | 4 | |||

| 总和 Sum | 88.46 | 8 | |||

| 小麦 Wheat | 工作转速 Working speed/(r∙min-1) | 63.00 | 2 | 182.47 | 0.000 1** |

| 入口压力 Air inlet pressure/Pa | 34.61 | 2 | 100.22 | 0.000 3** | |

| 误差 Error | 0.69 | 4 | |||

| 总和 Sum | 98.30 | 8 |

| 时间间隔 Time interval | 水稻 Rice | 小麦 Wheat |

|---|---|---|

| Δt1 | 11.1 | 8.0 |

| Δt2 | 7.0 | 8.0 |

| Δt3 | 10.1 | 7.2 |

| Δt4 | 9.0 | 9.8 |

| Δt5 | 10.2 | 9.7 |

Table 7 Seed spacing time

| 时间间隔 Time interval | 水稻 Rice | 小麦 Wheat |

|---|---|---|

| Δt1 | 11.1 | 8.0 |

| Δt2 | 7.0 | 8.0 |

| Δt3 | 10.1 | 7.2 |

| Δt4 | 9.0 | 9.8 |

| Δt5 | 10.2 | 9.7 |

延时时间 Time interval/ms | 水稻吹种数量 Number of blown rice seeds | 小麦吹种数量 Number of blown wheat seeds |

|---|---|---|

| 10 | 111.8 | 201.2 |

| 11 | 385.6 | 211.4 |

| 12 | 477.4 | 424.6 |

| 13 | 300.2 | 399.8 |

| 14 | 251.4 | 287.4 |

Table 8 Number of seed blowing under different delay time between grains

延时时间 Time interval/ms | 水稻吹种数量 Number of blown rice seeds | 小麦吹种数量 Number of blown wheat seeds |

|---|---|---|

| 10 | 111.8 | 201.2 |

| 11 | 385.6 | 211.4 |

| 12 | 477.4 | 424.6 |

| 13 | 300.2 | 399.8 |

| 14 | 251.4 | 287.4 |

| 1 | 丛锦玲,廖庆喜,曹秀英,等.油菜小麦兼用排种盘的排种器充种性能[J].农业工程学报,2014,30(8):30-39. |

| CONG J L, LIAO Q X, CAO X Y, et al.. Seed filling performance of dual-purpose seed plate in metering device for both rapeseed & wheat seed [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(8):30-39. | |

| 2 | 邢赫,臧英,王在满,等.水稻气力式分层充种室设计与试验[J].农业工程学报,2016,32(8):9-17. |

| XING H, ZANG Y, WANG Z M, et al.. Design and experiment of stratified seed-filling room on rice pneumatic device [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(8):9-17. | |

| 3 | 黄明涛.水稻机械化插秧技术分析与种植机械发展趋势探究[J].黑龙江科技信息,2016(3):261. |

| 4 | DICAJI H Z, TAHERI M R Y, MINAEI S. Air-jet seed knockout device for pneumatic precision planters [J]. Agric. Mech. Africa Latin Am., 2010, 41(1):45-50. |

| 5 | TOPAKCI M, KARAYEL D, CANAKCI M, et al.. Sesame hill dropping performance of a vacuum seeder for different tillage practices [J]. Appl. Eng. Agric., 2011, 27(2):203-209. |

| 6 | FURUHATA M, CHOSA T, SHIOYA Y, et al.. Developing direct seeding cultivation using an air assisted strip seeder [J]. Japan Agric. Res. Quarterly, 2015, 49(3):227-233. |

| 7 | 戴志刚,周先竹,王忠良,等.小麦-水稻轮作种植模式下秸秆机械化粉碎还田技术[J].农技服务,2014,31(11):34-35. |

| 8 | RAJAIAH P, MANI I, KUMAR A, et al.. Development and evaluation of electronically controlled precision seed-metering device for direct-seeded paddy planter [J]. Indian J. Agric. Sci., 2016, 86(5):598-604. |

| 9 | 梅志雄,夏俊芳,张居敏,等.稻麦两用螺旋舀种式排种器排种性能试验[J].华中农业大学学报,2020,39(5):136-146. |

| MEI Z X, XIA J F, ZHANG J M, et al.. Seeding performance of seed metering device with spiral tube scooping for rice and wheat [J]. J. Huazhong Agric. Univ., 2020, 39(5):136-146. | |

| 10 | 杜俊,夏俊芳,张居敏,等.稻麦兼用型气力滚筒精量排种器设计与试验[J].华中农业大学学报,2020,39(3):127-134. |

| DU J, XIA J F, ZHANG J M, et al.. Design and experiment of pneumatic drum type metering device for rice and wheat [J]. J. Huazhong Agric. Univ., 2020, 39(3):127-134. | |

| 11 | 何丽楠,赵明明,赵天才,等.稻麦兼用螺旋槽式排种器的设计与试验[J].湖南农业大学学报(自然科学版), 2019, 45(6):657-663. |

| HE L N, ZHAO M M, ZHAO T C, et al.. Design and experimental of the spiral trough seed metering for rice and wheat [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2019, 45(6):657-663. | |

| 12 | 唐楠锐,周勇,张国忠,等.搅种型孔式水稻穴播排种器的性能模拟与试验[J].中国农业科技导报,2022,24(4):107-115. |

| TANG N R, ZHOU Y, ZHANG G Z, et al.. Performance simulation and experiment of stirred and bunch rice seeding device [J]. J. Agric. Sci. Technol., 2022, 24(4):107-115. | |

| 13 | 曹成茂,秦宽,王安民,等.水稻直播机气吹辅助勺轮式排种器设计与试验[J].农业机械学报,2015,46(1):66-72. |

| CAO C M, QIN K, WANG A M, et al.. Design and experiment on rice hill seeder with air-blowing special hole and scoop-wheel [J]. Trans. Chin. Soc. Agric. Mach., 2015, 46(1):66-72. | |

| 14 | 赵晓顺,于华丽,马跃进,等.负压式小麦精量排种器参数优化与试验[J].农业工程学报,2017,33(11):11-18. |

| ZHAO X S, YU H L, MA Y J, et al.. Parameter optimization and experiment of negative pressure precision seed-metering device for wheat [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(11):11-18. | |

| 15 | 赵金,郑超,张晋国,等.差速充种沟式小麦单粒排种器优化设计与试验[J].农业机械学报,2020,51(12):65-74. |

| ZHAO J, ZHENG C, ZHANG J G, et al.. Parameter optimization and experiment of differential filling groove single grain seed-metering device for wheat [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(12):65-74. | |

| 16 | 梁玉玥,郑侃,杜俊,等.稻麦兼用排种器振动供种装置性能试验[J].沈阳农业大学学报,2021,52(6):708-717. |

| LIANG Y Y, ZHENG K, DU J, et al.. Performance test on vibrating feeder of seed metering device [J]. J. Shenyang Agric. Univ., 2021,52(6):708-717. | |

| 17 | 雷小龙,廖宜涛,王磊,等.油麦兼用型气送式集排器增压管气固两相流仿真与参数优化 [J].农业工程学报,2017,33(19):67-75. |

| LEI X L, LIAO Y T, WANG L, et al.. Simulation of gas-solid two-phase flow and paramerer optimization of pressurized tube of air-assisted centralized metering device for rapeseed and wheat [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(19):67-75. | |

| 18 | 许虎,吴文勇,王振华, 等.基于CFD的斜三通管水力特性分析及流场计算[J].排灌机械工程学报,2020,38(11):1138-1144. |

| XU H, WU W Y, WANG Z H, et al.. Hydraulic characteristics analysis and flow field calculation of inclined tee pipes based on CFD [J]. J. Drain. Irri. Mach. Eng., 2020, 38(11):1138-1144. | |

| 19 | 朱彤,丛锦玲,齐贝贝, 等.机械气力组合式花生精量排种器设计与试验[J].中国机械工程,2020,31(21):2592-2600. |

| ZHU T, CONG J L, QI B B, et al.. Design and test of mechanical-pneumatic combined peanut precision metering device [J]. China Mech. Eng., 2020, 31(21):2592-2600. | |

| 20 | 张甜,蒋乐,李兆东, 等.光纤计数式油菜精量排种器种子流检测系统研究[J].农业机械学报,2023,54(1):64-74, 145. |

| ZHANG T, JIANG L, LI Z D, et al.. Study on seed flow detection system of fiber counting precision seed metering device for rape [J]. Trans. Chin. Soc. Agric. Mach., 2023, 54(1):64-74, 145. |

| [1] | Zheng QIAN, Sunzhe YANG, Guoqing ZHANG, Ziwei GUO, Linpeng ZHANG, Jiaxing WAN, Hongyun YANG. Rice Nitrogen Nutrition Diagnosis Based on Convolutional Neural Network [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 113-121. |

| [2] | Huijun LI, Weijian ZHANG, Weijian WU, Gaoyang LI, Yijie CHEN, Fengcheng HUANG, Yongxiang HUANG, Zhong LIN, Zhen ZHEN. Effects of Sea Rice on Soil Chemical Properties and Microbial Community Structure in Coastal Solonchaks [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 147-156. |

| [3] | Jingjuan GAO, Chenyu ZHU, Yuqin KE, Chaoyuan ZHENG, Chunying LI, Wenqing LI. Effects of Organic Fertilizer Application Period on Carbon and Nitrogen Metabolism in Flue-cured Tobacco Under Tobacco-Rice Rotation [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 157-165. |

| [4] | Shegang SHAO, Ting LI, Yong LIU, Lanwen LIN, Dong ZHANG, Dong NI, Junjie LI, Li’an ZHU. Effects of Exogenous Promoting Bacteria Agent on Decomposition Characteristics and Microbial Community Structure of Rice Straw [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 166-177. |

| [5] | Lili SHAN. Effects of Low Temperature During Booting Stage on Rice Physiology and Alleviating Effect of Exogenous Melatonin [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 23-33. |

| [6] | Ying ZHOU, Jingyong LI, Linxiu DAI, Dicai AO, Ziyi LI, Fan YANG, Junwei GU, Qiang XU, Zhi DOU, Hui GAO. Effect of Melatonin Spraying on Rice Yield Formation and Lodging Resistance Under Rice-Crayfish Coculture Mode [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 34-42. |

| [7] | Xuemin JIANG, Xiangqian CHEN, Hongyan LI, Qiyan JIANG. Metabolomic Analysis of Wheat Response to Salt Stress [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 43-56. |

| [8] | Mingyu ZHAO, Hao JIA, Xiaoyu SHI, Yi PAN, Yuyun HUANG, Kaicheng WANG, Qingquan CHU. Distribution of Winter Wheat Water Footprint in Huang-Huai-Hai Farming Region in Recent 30 Years [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 138-147. |

| [9] | Zhigang ZHENG, Li XIANG, Gongyi LIU, Cai XU, Bin QIN, Weiqin WANG, Huabin ZHENG, Qiyuan TANG. Effects of Nitrogen Application Rate and Density on Growth and Yield of Orderly Machine-thrown Early Rice [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 132-143. |

| [10] | Feifan HOU, Xiaowen ZHANG, Jiaqi WANG, Jianzhen ZHANG, Kaiquan LI, Xuebin YIN. Effect of Selenium Fertilizer Application Position on Physiological Characters and Selenium Accumulation in Wheat [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 144-152. |

| [11] | Dongmeng ZHANG, Dongping YAO, Jun WU, Qiuhong LUO, Wen ZHUANG, Xionglun LIU, Qiyun DENG, Bin BAI. Effect of Natural Low Temperature on Cooking and Eating Quality of Rice During Grain Filling Stage [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 144-153. |

| [12] | Hongyuan LIU, Zhihua ZHOU, Guangxin ZHAO, Yanjun WANG, Nana WANG. Effects of Modified Cellulose on Germination and Dryland Soil Physicochemical Properties of Upland Rice [J]. Journal of Agricultural Science and Technology, 2023, 25(5): 168-175. |

| [13] | Chen CHEN, Ke SHI, Changwei ZHU, Guiying JIANG, Lan LUO, Weiwei MENG, Fang LIU, Fengmin SHEN, Shiliang LIU. Effects of Planting Density and Nitrogen Application Rate on Wheat Photosynthetic Characteristics, Yield, and Soil Nitrogen Content in Fluvo-aquic Soil in Northern Henan Province [J]. Journal of Agricultural Science and Technology, 2023, 25(5): 24-33. |

| [14] | Fenfang XIAO, Conghe ZHANG, Hui WANG, Yafeng YE, Daolin ZHANG, Heting WANG, Bo LI, Yuejin WU, Binmei LIU. Simulation and Optimization of Pneumatic Conveying System for Hybrid Rice Pollen Collection Device [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 110-122. |

| [15] | Yanjun KE, Yumeng ZHANG, Yanjie GUO, Lijuan ZHANG, Zitao ZHANG, Yanzhi JI. Effects of Bio-organic Fertilizer Combined with Subsoiling on Farmland Soil Fertility and Crop Yield [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 157-166. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号